Company News

10 steps of common material testing machine loading

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Material testing machineThere are often problems of this kind and that kind of problems during use, but the common problems that arise when loading data are as follows 10 aspects for reference by customers.

1. Lack of oil volume in the fuel tank. When loaded to the inevitable load, there is a "puff" or "puff" sound when the oil supply valve returns to the oil pipe, and there is little oil output and there are bubbles. When the load cannot rise again, no oil flows out of the return oil pipe. Cleaning method: Recharge oil into the test engine oil tank until the oil level reaches half of the oil viewing window.

2. The viscosity of oil is too low (the oil is constantly flowing out of the oil return pipe of the oil supply valve when loading). Ordinary mineral oil with medium viscosity is used, which does not contain water, acid and other inclusions, does not differentiate at room temperature, and does not thicken. It can be measured by a viscometer when needed. If the oil is not used properly, the valve and oil circuit will be inflated and can cause vibration or pipeline leakage. Oil should be used as required by the imitation order.

3. The oil pressure system of the test engine has serious oil leakage. The oil leakage in the oil circuit system is usually present at the connection of the buffer valve, oil return valve, oil supply valve, oil pump and pipeline. Just tighten the screws after adding pads. If the sealing gasket is broken, it must be removed and replaced with a new one. The gaskets should be made of copper or aluminum alloy.

4. The oil collector of the oil pump is not pressed on the pump body. In this way, each load can only reach the inevitable load, and the load cannot rise again, and the oil return pipe of the oil supply valve will not flow out. Sweep method: Use a wrench to tighten the fixing screws at the rear end of the oil pump. If there is still a problem, remove the oil collector and add a gasket between the oil collector and the pump body.

5. The common gap between the task piston and the oil cylinder is too large, and the gap is too oil spilled, which can be seen from the oil spill and other outlets. The method is to thicken the viscosity of the oil. If the problem cannot be handled, after careful measurement, you should go to the factory to exchange the piston and oil cylinder.

6.Testing machineThe gap between the force-measuring piston and the force-measuring cylinder is large. When it reaches a high tonnage, it can be seen from the lower part of the force-measuring cylinder. Normally, there is no oil drop or intermittent drops when there is high tonnage. If it flows out in a linear shape, it is explained that the force measuring piston should be replaced. When checking for oil leakage, you should pay attention to the difference between oil leakage at the joint and oil leakage at the cylinder plug, and you should not make a mistake in making a mistake because of misreading.

7. The piston and piston sleeve in the oil supply valve are damaged or the spring becomes soft. In this way, the load that can be reached by each load remains unchanged at all, and the oil supply valve is noisy. When the load cannot rise again, the oil output of the oil supply valve return pipe is large. The piston and piston sleeve should be taken out and ground. If the damage is serious, the spring should be replaced.

8. The oil supply valve has low stiffness in the spring, or saves the needle cavity and has infarction. The first thing to do is to show: each load can only reach the inevitable load. When the load cannot rise again, the oil output of the return oil pipe is large. Cleaning method: Change the pressure-regulating spring with suitable stiffness or clean dirt.

9. The gap between the damping needle and the damping hole of the oil supply valve is too small. The first display is that each load can only reach the inevitable load. When the load cannot rise again, the oil output of the oil return pipe of the oil supply valve is large. Sweep method: Take out the damping needle and use a file to properly file a part along the axial direction of the damping needle.

10. The belt that drives the oil pump to loosen and there is a slippage. After loading to a certain load, the oil supply valve returns to the oil pipe without oil flowing out, and the oil pump has no sound. Cleaning method: loosen the electric thought fixing screw, adjust the position, tighten the belt, and then tighten the electric thought fixing screw. If the belt is too deformed, a new belt must be replaced.

11. The oil pump plunger is rusted. The primary display: During the loading process, the oil output from the oil supply valve return pipe does not continue or is shaken. When a certain load cannot rise again, no oil flows out of the return oil pipe. Cleaning method: Take out the plunger and polish it again.

12. For test machines with fuse valves, when the load exceeds 3% to 5%, they can be turned on automatically, ensuring that the test machine will not be damaged due to excessive overload. When the safety valve is not properly conditioned, or when the valve tip and hole are not blocked tightly, the pressure will not be high. The adjustment method is to disassemble the safety valve regulating screws, reflect on the damage of parts and exchange them. If there is too much overload, rotate the screw downwards and vice versa.

MoreMaterial testing machineAll in Jinan Hengsi Shanda Instrument Co., Ltd.

- Previous article:Historical facts about the test machine

- Next article:Process of cantilever beam impact test machine

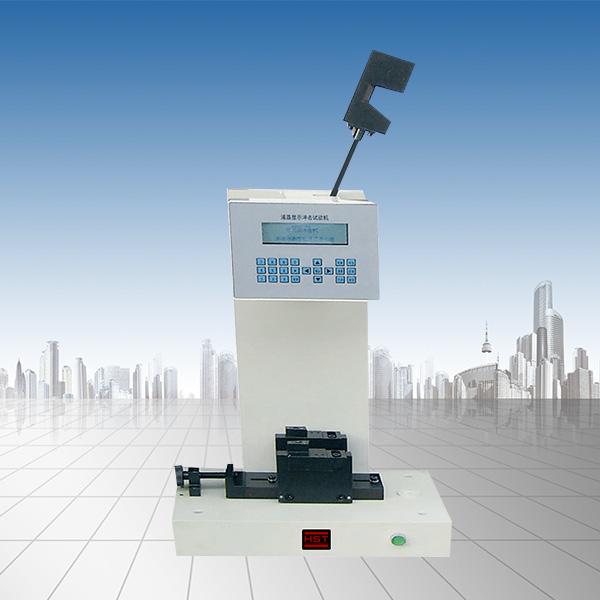

Recommended productsPRODUCTS