Industry Information

Comparison of experimental standards in China, the United States, Japan and other countries

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Recently, customers often ask about international standards such as the US standards and European standards. Because there are many standards and are not unified with the domestic standards, some customers are a little confused when asking. Here we briefly compare the test machine indicators of different countries, hoping to help you.

Tensile test is one of the commonly used test methods in the mechanical properties of most materials. In the experiment, data on various stages such as elastic variables, shaping variables, fractures, stretching, etc. were obtained to reflect the entire process of the material's resistance to external forces. The electronic universal testing machine has the characteristics of being simple and easy to prepare samples. The performance data detected in this experiment has very important application and reference value for design and material selection, new material development, procurement acceptance, quality control and safety assessment, etc.

The tensile test standards of different countries, the processing of test processes and results of the test machine are somewhat different from the regulations. We now compare the tensile test standards of metal materials from Japan, the United States and China. If you need more detailed information, please call and write to Jinan Hengsi Shanda Instrument Co., Ltd., and we will fully cooperate with your work.

1: Extension Measure.

1. Regulations on extensometers in E 8/E 8M-08, A 370-07 and ISO system standards

E 8/E 8M-08 A 370-07 ISO standard

Measurement parameters and range Level and accuracy min Measurement parameters and range Level and accuracy min Measurement parameters and range Level and accuracy min

Rp, Rt ±0.5% (grade B2) Rp and At ±0.5% (grade B2) Rp, Rt and Ae ±1% (grade B2)

Ag or Agt, A or At <5% ±0.5% (grade B2) Ag or Agt, A or At <5% ±0.5% (grade B2) Ag or Agt, A or At ±2% (grade B2)

5~50 5~50 ±1% (Class C)

≥50 ±2% (Grade D) ≥50 ±2% (Grade D)

※ E 8/E 8M-08 regulations:

Measure the non-proportional extension strength Rp, the specified total extension strength Rt and the yield point elongation Ae, and the extensometer gauge distance should be less than or equal to the gauge distance of the sample.

If a sample without shoulders is selected, the distance between the extensometer should be less than 80% of the distance between the collets when the sample is clamped on the test machine.

When determining elongation A after break or total elongation A after break, the extensometer gauge distance should be equal to the gauge distance of the sample. E 8/E 8M-08 stipulates that for most metal materials, the recommended calibration strain range is 0.2-2.0%.

In addition to the content listed below, the provisions of A 370-07 on the accuracy of extensometers are basically the same as those of E 8/E 8M-08. When measuring the specified Rp, when the non-proportional extension is greater than or equal to 0.2%, an extensometer (level B2 and above) with an accuracy of not less than ±0.5% should be selected for calibration in the strain range of 0.05 to 1.0%; when the non-proportional extension is less than 0.2%, an extensometer (level B1 and above) with an accuracy of not less than ±0.25% should be selected for calibration in the strain range of 0.05 to 1.0%, or an extensometer (level B2 and above) with an accuracy of not less than ±0.5% should be selected and the lower limit of the calibration strain range is reduced (for example, reduced to 0.01%). When determining the specified total extension strength Rt, an extensometer (grade B1 and above) with an accuracy of no less than ±0.25% should be selected.

※ ISO system standards stipulate:

When measuring yield behavior, the gauge distance of the extensometer should not be less than 1/2 of the gauge distance of the sample.

When determining the elongation A after break or the total elongation A of the fracture, the gauge distance should be equal to the gauge distance of the sample.

Summary: 1 is the provisions of the extensometers in E 8/E 8M-08, A 370-07 and ISO system standards. It can be seen from Table 1: For the requirements of the extensometer, the requirements of the ASTM standard are similar to the resolution requirements of the ISO system standards for the sample size measurement device; for the width of the plate sample, the requirements of A 370-07 are lower than those of E 8/E 8M-08 (0.13 vs 0.02mm). Except for the provision of 1, for specimens with small sizes less than 0.5 mm, E 8/E 8M-08, which stipulates that if possible the resolution is not greater than 1% of the small size of the specimen.

For asymmetric full-section samples, when using weighing method, E 8/E 8M-08 stipulates that the length of the sample is greater than 20 times the size on the cross-section, and the sample mass measurement accuracy should be no less than 0.5%.

The ISO system standard is strict and provides the calibration range of the extensometer when performing corresponding measurements. The ISO standard provides the lower limit of the extensometer gauge distance when measuring yield behavior, which helps reduce controversy during testing.

2. Sample size measurement device

2. Regulations on the resolution of sample size measurement devices by E 8/E 8M-08, A 370-07 and ISO system standards

E 8/E 8M-08

E 8/E 8M-08 A 370-07 ISO standard range (mm) Resolution (mm) Range (mm) Resolution (mm) Range (mm) Resolution (mm)

<0.5 0.002 Plate sample width 0.13 0.1~0.5 0.001

0.5~2.5 0.002 Width of plate sample 0.025 0.5~2.0 0.005

2.5~5 0.01 Rectangular specimen thickness 2.0~10 0.01

≥5 0.02 Cylindrical sample diameter ≥10 0.05

2 is the resolution of the sample size measurement device by E 8/E 8M-08, A 370-07 and ISO system standards. As can be seen from Table 2, the ASTM standard and the ISO system standard have similar resolution requirements for the sample size measurement device; for the width of the plate sample, the requirements of A 370-07 are lower than those of E 8/E 8M-08 (0.13 vs 0.02mm)

. Except for the provisions of 2, for specimens with small sizes less than 0.5mm, E 8/E 8M-08, if possible, the resolution is not greater than 1% of the small size of the specimen.

. Zhongbao Testing Equipment Co., Ltd.

For asymmetric full-section samples, when using weighing method, E 8/E 8M-08 stipulates that the length of the sample is greater than 20 times the size on the cross-section, and the sample mass measurement accuracy should be no less than 0.5%.

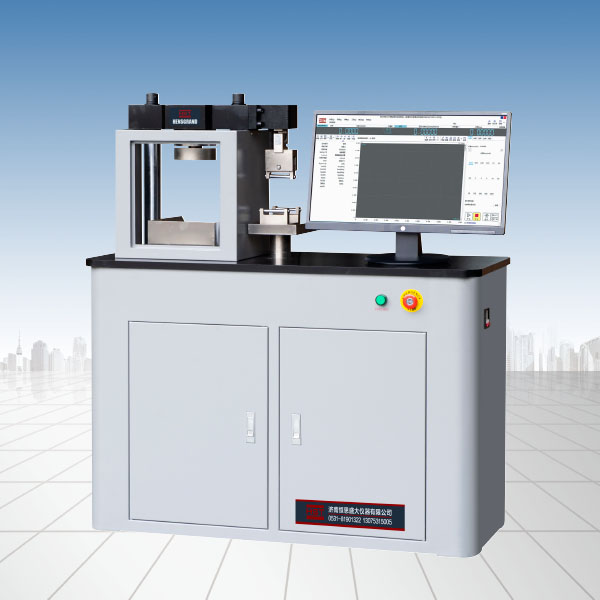

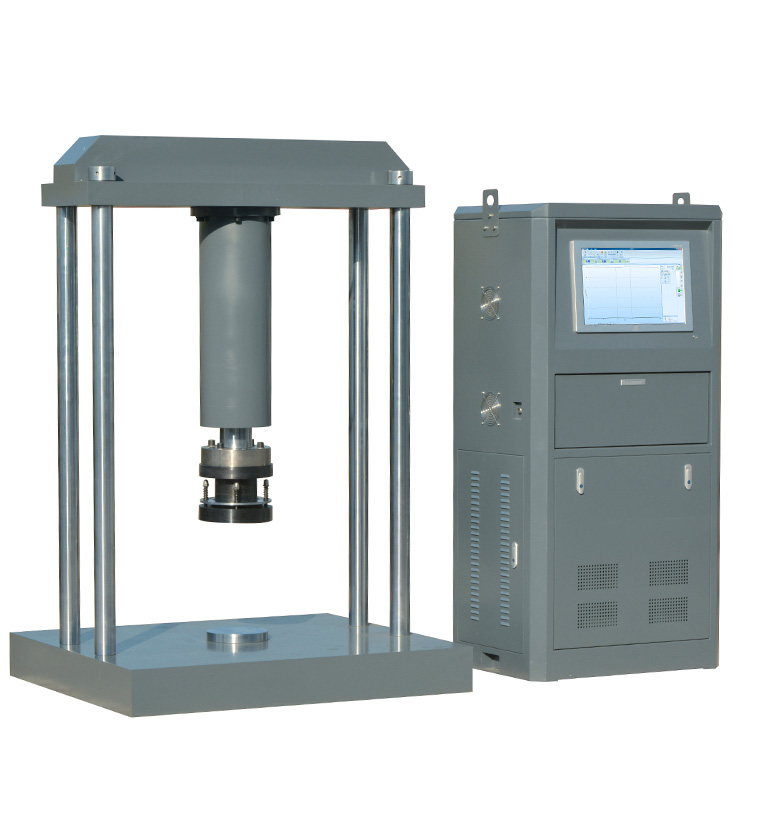

Recommended productsPRODUCTS