News

Operating specifications for drop test machine

Release time:2019-04-11 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

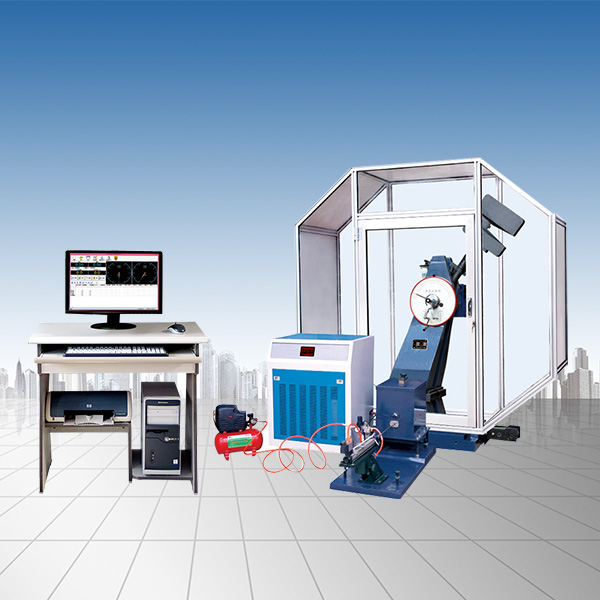

The drop tester can conduct free drop tests on the surface, angle and edge of the packaging, and is equipped with a digital height display instrument and a decoder for height tracking, so that the product drop height can be accurately given, and the error with the preset drop height is no more than 2% or 10mm. This machine adopts a single-arm double-column structure, with electric reset, electronically controlled drop and electric lifting devices: easy to use; the unique hydraulic buffering device greatly improves the service life, stability and safety of the machine. Single-arm setting allows easy placement of products, and the angle error of the impact surface and the floor plane of the drop angle is less than or equal to 5. Below I will share with you the operating specifications of the fall test machine.

Operating specifications of fall test machine

1. Wiring: Connect the randomly included power cord to the three-phase power supply and ground it, and use randomly to carry the control box and the test machine;

The connection wire is connected according to the adaptation of the plug, and the rising/fall command is tested. (If the rising key is pressed during the trial operation but runs downward or the falling key is pressed but the rising key is pressed, you only need to change the phase number at the power supply;

2. Adjustment of drop height:

3. Place the object to be tested on the workbench and fix it with a fixing rod;

4. Press the rise button on the drop test machine to raise the object to be measured to the set height;

5. Press the drop button to instantly disengage the work surface from the measured object, and the measured object will fall freely;

6. Press the reset key to restore the workbench to its working state;

7. If the test is repeated, repeat the above steps;

8. After the test of the drop test machine: Press the lower key to make the work surface operate to the lowest position and turn off the power button.

Mechanical equipment is essentially the same. Only by mastering the correct method can the entire experimental process be smoother and the experimental data are more accurate. The above are the operating specifications of the drop test machine, and I hope it can help you.

Recommended productsPRODUCTS