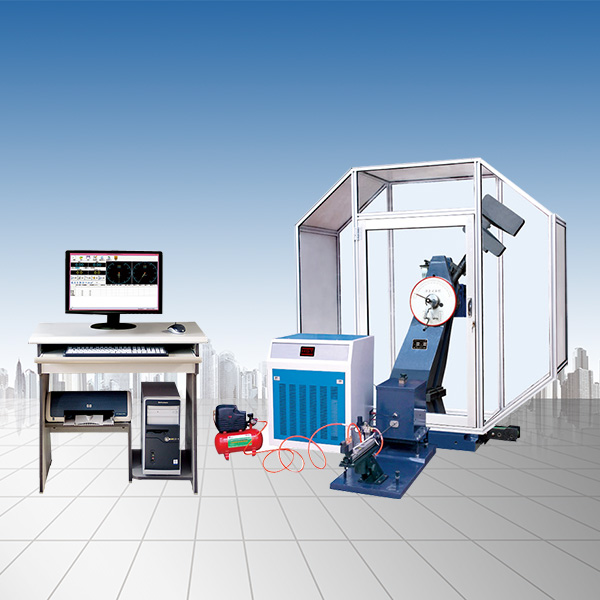

Microcomputer-controlled ultra-low temperature fully automatic impact tester JBDW-300C

Microcomputer-controlled ultra-low temperature fully automatic impact tester JBDW-300C

1. Performance description

JBDW-300C low-temperature impact testing machine is used to test the performance of metal materials to resist impact under dynamic loads. It is an essential testing instrument for metallurgical machinery manufacturing and other units, and is also an indispensable testing instrument for scientific research institutions to conduct new materials research.

1. This machine adopts fully automatic control, and the swing, hanging, feeding, positioning, impact and temperature adjustment equipment are all electrical and mechanically controlled. It is equipped with a special feeding device to automatically feed the material and automatically position the sample cross-section. The impact time until the sample is released from the oven is no more than 2 seconds, which meets the requirements of the metal low temperature chamonix impact test method. After impacting the sample, the remaining energy can be used to automatically swing, and prepare for the next test, which has high working efficiency;

2. The main body of the test machine is a split structure, cantilever hanging pendulum method, and the pendulum hammer body U-shaped;

3. The impact knife is installed and fixed with screws, making it easy to replace;

4. Sample simple-supported beam type support;

5. The host is equipped with a security protection pin and is equipped with a security protection net;

6. The test machine complies with the national standard GB/T3803-2002 "Inspection of Pendulum Impact Test Machine", and conducts impact tests on metal materials according to the national standard GB/T229-2007 "Metal Shabby Notch Impact Test Method".

2. Main technical parameters:

1. Impact energy: 150J, 300J

2. Pendulum pre-raising angle: 150°

3. Distance from center of the swing shaft to impact point: 750mm

4. Impact speed: 5.2m/s

5. Span of sample bearing: 40mm

6. Claw rounded corners: R1-1.5mm

7. Impact blade rounded corner: R2-2.5mm

8. Impact knife thickness: 16mm

9. Refrigeration method: liquid nitrogen refrigeration

10. Sample box capacity: 6

11. Low temperature range: 0-----196℃

12. Temperature control accuracy: fluctuation ±1.5℃, gradient 2℃

13. Sample size: 10×10×55mm

14. Dimensions: 1500 mm×850 mm×1340 mm

15. Net weight of test machine: 650Kg

16. Power supply: AC three-phase 380V±10% 50HZ 5A

17. Environmental conditions: There is no corrosive medium around, no vibration, and no strong electromagnetic field.

5. Main equipment configuration:

1. One 300 Joule host;

2. One pendulum with 150J and 300J

3. One motor (installed on the host);

4. Take a set of pendulum transmission devices (installed on the main machine);

5. A set of automatic hanging device (installed on the host);

6. A set of refrigeration temperature control devices;

7. A set of automatic feeding devices (installed on the main machine);

8. A set of safety protection networks;

9. One support calibrator;

10. One sample centering device;

11. One disassembler (change for pendulum)

12. Approach a proximity switch;

13. A set of special measurement and control software

14. One brand microcomputer and one printer

15. Four anchor screws

16. Adjust the slanted iron four pieces

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

Recommended informationNEWS

- [2023-07-06]Anchor cable dynamometer for coal mines

- [2023-07-06]Steel core aluminum stranded wire tensile testing machine

- [2023-07-06]Prestressed steel strand tensile test machine

- [2023-07-06]Steel strand tensile tester

- [2023-07-06]Steel strand test machine

- [2023-07-03]Chain horizontal tensile testing machine

- [2023-07-03]Ring chain horizontal tensile testing machine

- [2023-07-03]Chain tensile testing machine

- [2023-07-03]Projects that can be tested by electronic tensile testing machines

- [2023-02-23]Metal impact tester

- [2023-02-16]Things to note when operating the electronic universal testing machine software

- [2023-02-16]Impact testing machine Pendulum impact testing machine selection

- [2022-11-30]What should be paid attention to when operating the electro-hydraulic servo universal test machine?

- [2022-11-30]Electronic tensile testing machine

- [2022-11-30]What is the maintenance of the impact test machine?

- [2022-11-04]Standard impact test method for metal material notch specimens

- [2022-11-04]1000KN digital display manhole cover pressure tester

- [2022-11-04]Rubber material tensile testing machine