News

Working conditions of rubber tensile testing machine

Release time:2019-05-22 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

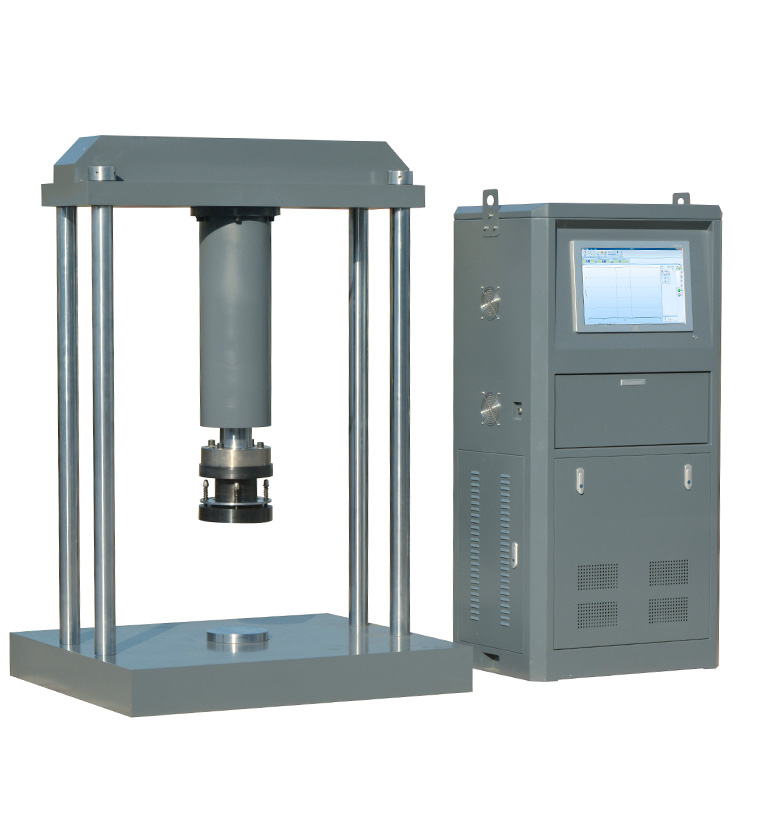

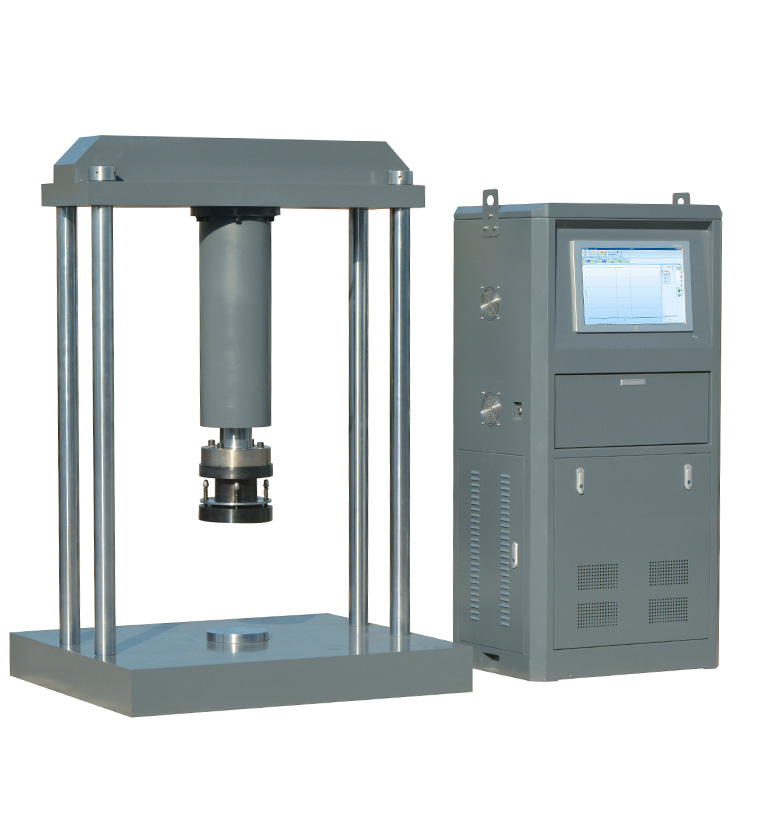

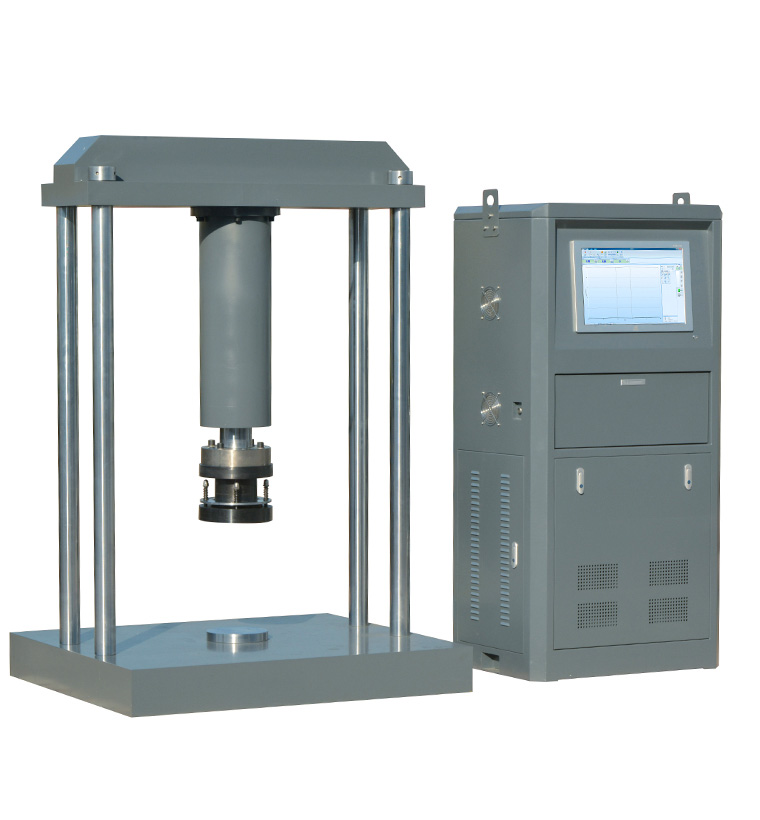

The rubber tensile testing machine is not only suitable for rubber but also for adding accessories. It can also be used for tensile testing, compression and bending tests of plastics, textiles, waterproof materials, wires, cables, mesh ropes, metal wires, metal rods, metal plates and other materials. It has functions such as digital display of test force, continuous adjustment of test speed, automatic shutdown of sample pull-off, peak maintenance and other functions.

The rubber tensile tester uses an integrated structure of the DC servo motor and speed regulation system to drive the synchronous belt deceleration mechanism, and after deceleration, the lead screw pair is driven to load. The electrical part consists of a load measurement system and a deformation measurement system. All control parameters and measurement results can be displayed in real time on the large screen LCD. It also has functions such as overload protection and displacement measurement. Suitable for performance testing of rubber, composite film, soft packaging materials, adhesives, adhesive tape, self-adhesive, rubber, paper and other products; it can save test data and results 6 times, and has necessary functions such as curve display and query. However, the working conditions of the rubber tensile testing machine are also very important. Let’s introduce it below:

Working conditions of rubber tensile testing machine:

1. Within the room temperature range of 10℃-35℃, the relative humidity shall not exceed 80%;

2. Install correctly on a solid foundation or workbench;

3. In a vibration-free environment;

4. No corrosive media around;

5. The fluctuation range of the power supply voltage should not exceed ±10% of the rated voltage;

6. The power supply of the test machine should be reliable grounded; the fluctuation of the frequency should not exceed ±2% of the rated frequency;

7. Install correctly on a solid basis.

With the continuous development and progress of science and technology and the continuous development of various industries, new requirements have been put forward for rubber tensile testing machine equipment and play an increasingly important role in various industries. Competition for rubber tensile testing machines is becoming increasingly fierce, while highly automated, intelligent, multi-functional, high-efficiency and low-consumption tensile testing machines and equipment are becoming increasingly popular in the industry. The degree of automation of process flow is getting higher and higher. The working conditions of using rubber tensile testing machines have also been improved, and the working conditions are also an important factor that determines the service life of the machine! I hope this article will be helpful to everyone!

Recommended productsPRODUCTS