News

Common methods for troubleshooting buttons in paper tensile testing machines

Release time:2019-05-24 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

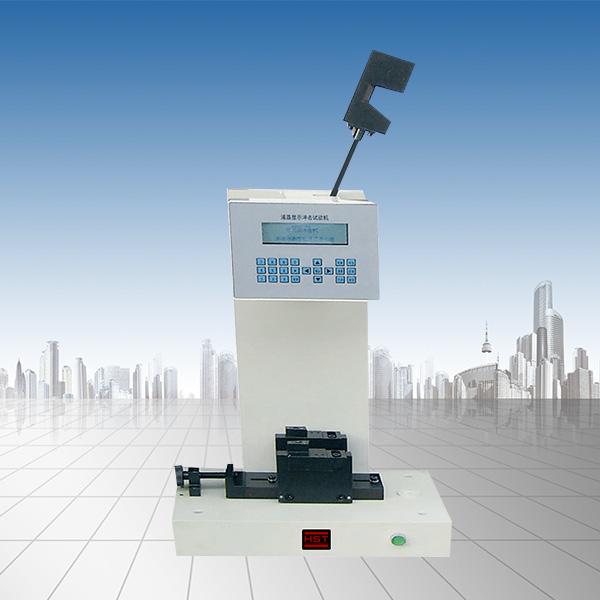

Paper tensile testing machine, also known as electronic tensile machine, can perform mechanical properties tests such as tensile, compression, bending, shear, and peeling. In terms of paper product testing, it is used to evaluate the fracture strength, tensile fracture load, fracture length and crack resistance coefficient of pulp and paper. It is an indispensable testing equipment in paper testing instruments.

Any machine will have problems or problems during use, causing troubles in related work. Today, our company's technicians will summarize some common button troubleshooting methods for paper tensile testing machines, helping everyone to troubleshoot problems and restore the normal operation of paper tensile testing machines as soon as possible.

1. The paper tension tester has no response to operation: the most common thing is that the rising key and falling keys of the beam have no response. Such a glitch causes the device to fail to work.

2. The operation of the paper tension tester is confusing: the main reason is that the functions of each key are inconsistent. Due to the transmission signal problem, the functions of the keys overlap and intersect each other, resulting in the failure of the experiment.

The above are two of our most common operations about touching keys. In order not to affect our experimental results and extend the service life of the experimental equipment, users must learn to solve the above simple fault problems by themselves. Everyone must keep in mind the next few key points to avoid causing unnecessary trouble to users.

1. For the situation where the paper tension tester has no response, first of all, it is necessary to determine whether the external power supply and transmission signal cable of the control box are connected correctly. If the rising key and falling key do not respond, the user can try to press other keys such as speed key, return key, clear key, calibration key and other buttons to see if they are responded. If none of them are responded, the greatest possibility is the connection problem of the external power supply. If it is just simply rising and falling, then the tester needs to be checked whether the limit protection device switch is touched. After checking and confirming that the above problem still occurs, it means that it is an internal problem of the instrument box. At this time, the manufacturer needs to carry out the next step of work.

2. Do not place the paper tension tester in places with high temperature, high humidity and strong magnetic fields. The magnetic field will affect the sensitivity of the buttons, and a humid environment will accelerate the damage of the electronic components of the instrument box, resulting in unpredictable problems. If the electronic components are damaged, this can only be replaced by the manufacturer.

The above is the common button troubleshooting method for paper tensile testing machines I shared with you. I hope it can help users solve their problems. If you have any questions during use, you can call our service hotline through the web page, and our company will arrange technicians to answer you. Welcome to call and support!

Recommended productsPRODUCTS