News

Components and functions of electronic universal tensile testing machine

Release time:2019-04-30 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

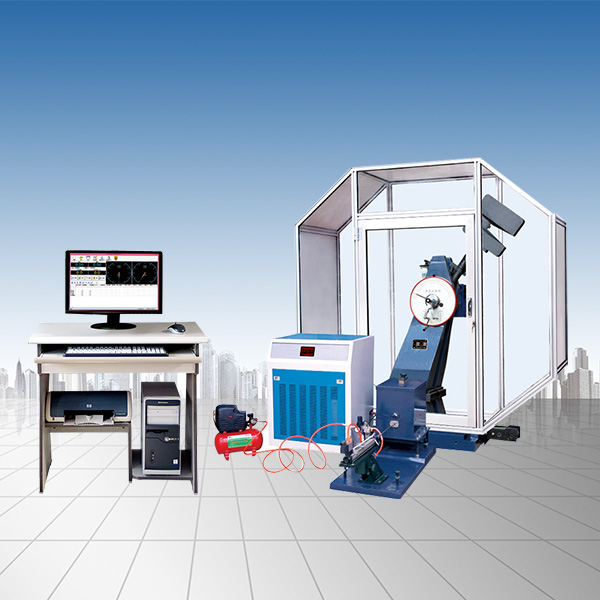

The electronic universal tensile tester is a new generation of dual-space microcomputer controlled electronic universal tester designed specifically for universities and research institutes. The computer system controls the rotation of the servo motor through the speed control system, and after deceleration, the speed reduction system drives the moving crossbar to rise and fall through the precision lead screw pair, completing the test sample's mechanical properties such as tensile, compression, ring stiffness, bending, shear, etc. In addition, it is equipped with a wide variety of test accessories, which has very broad application prospects in the mechanical properties test of metals, non-metals, composite materials and products. This time I will share with you the components and functions of the electronic universal tensile testing machine.

The electronic universal tensile testing machine mainly includes 1. Software control part 2. Motor 3. Transmission part 4. Screw 5. The main components of the sensor are analyzed from these aspects.

1. Software and hardware

With the maturity of electronic universal tensile testing machine technology, many companies have begun to develop control software. A software with good performance is improved through practice. The newly opened software functions can be realized, but the stability and data acquisition accuracy may vary greatly. The motor sensor used is very accurate, but the software acquisition frequency is relatively low, so it cannot achieve its effect at all.

2. Motor

Most electronic universal tensile testing machines adopt an AC servo speed regulation system, with stable and reliable performance, and have protection devices such as overcurrent, overvoltage, and overload. There is also an electronic universal tensile testing machine on the market that uses ordinary three-phase motors or variable frequency motors. This motor uses analog signal control, slow control reaction and inaccurate positioning. Generally, if the speed regulation range is narrow, there will be no low speed or if there will be low speed, there will be no high speed, and the speed control will be inaccurate.

3. Transmission system

There are two main transmission parts of the electronic universal tensile tester: one is the arc synchronous gear belt and the precision lead screw secondary transmission; the other is the ordinary belt transmission. The first transmission method is smooth, has low noise, high transmission efficiency, high accuracy and long service life. The second transmission method cannot guarantee the synchronization of the transmission, so the accuracy and stability are not as good as the first transmission system.

4. Ball screw

The ball screw and important components in the transmission of the electronic universal tensile test machine are now used in ball screw and trapezoidal screw. Generally speaking, the gap between trapezoidal lead screws is relatively large, the friction force is relatively large, and the service life is short. If a trapezoidal lead screw is used, the assembly accuracy of the entire test machine will be greatly reduced.

V. Sensor

Sensors are important components of the accuracy and strength stability of the test machine. Currently, the types of electronic universal tensile test machine sensors on the market include S-type and spoke type. The internal resistance strain gauge of the sensor is not very accurate, the glue used to fix the strain gauge is poor in aging resistance, and the poor material of the sensor will all affect the accuracy of the sensor.

To sum up, it is a related introduction to the components and functions of the electronic universal tensile tester. In the process of selection, users can make choices based on their own situation. Only by having a certain understanding of it can users choose products and equipment that are more suitable for them. Friendly reminder: If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

- Previous article:Structure and test principle of hammering Brinell hardness meter

- Next article:Working conditions of rubber tensile testing machine

Recommended productsPRODUCTS