News

What are the technical requirements for creep testing machine

Release time:2019-06-13 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

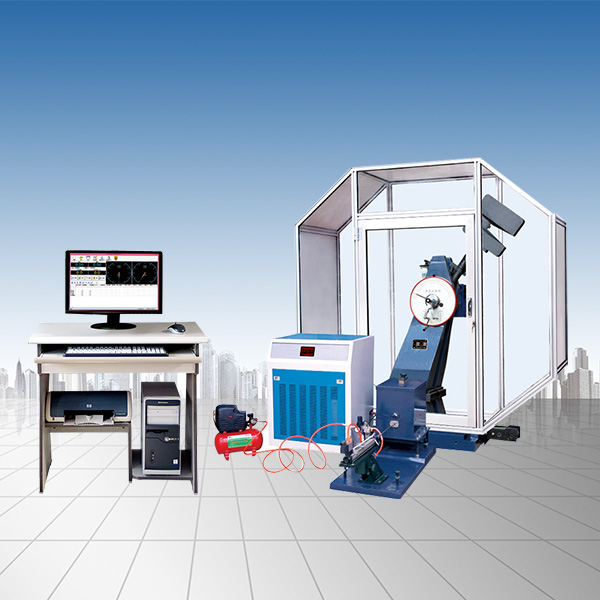

Creep testing machine, English name: Creeptesting machine, is used for tensile, compression durability, creep and relaxation tests of metal and non-metals. The creep tester is mainly used for tensile, compression durability, creep, relaxation tests, as well as low-cycle fatigue and creep fatigue tests of metal and non-metallic materials. The test method meets the relevant provisions of GB/T2039-1997 "Metal Tensile Creep Test Method", HB5151-1996 "Metal High Temperature Tensile Creep Test Method", HB5150-1996 "Metal High Temperature Tensile Test Method" and JJG276-88 "High Temperature Creep and Long-lasting Strength Test Machine". So what are the technical requirements for creep testing machines? Let me introduce it below:

Creep test machine test technical requirements:

1. Environment and working conditions: The test machine should be able to work normally under the following conditions

a) Room temperature within the range of 10℃-35℃;

b) The relative humidity is not greater than 80%;

c) In an environment without corrosive media around;

d) The fluctuation range of the power supply voltage is within ±10% of the rated voltage;

e} Correctly installed on solid foundation soil, level is 02/100;

2. Testing machine after-force, force measurement and deformation measurement device

2.1 The center lines of the upper and lower chucks of the test machine should be consistent, and the relative difference between the deformation of the two relative directions of the sample should not exceed 15%.

2.2 The test force applied or removed by the test machine should be stable and without vibration, and should be kept constant during the test.

2.3 The test force is within the range of 5%~100% of the maximum test force, and the maximum display value relative error of the force is ±1%.

2.4 The indication accuracy of the deformation measurement device should not be less than 0002mm

Note: Deformation measuring device with a minimum index value of Q01m can also be used.

3. Heating device, temperature measurement and control device

3.1 The heating device should ensure that the sample is heated evenly to the specified temperature, and the degradation remains stable throughout the test time: the temperature fluctuations and temperature gradients (temperature difference) at any point within the sample gauge distance should comply with the provisions of Table I.

3.2 The sensitive element for measuring temperature is a thermocouple sample with a gauge distance equal to or greater than 10m and is uniformly distributed within the gauge distance for the sample; a sample with a gauge distance less than 100mm and is distributed at both ends of the gauge distance for measurement.

3.3 The thermocouple hot end should be in close contact with the sample surface and prevent the influence of the heat radiation on the hot furnace wall; the cold end of the thermocouple compensation wire should be maintained at a constant temperature.

3.4 Thermocouple must pass the third-class standard thermocouple technology to ensure that the allowable errors should be subject to the total measurement verification regulations.

Any test machine has certain technical requirements, so are you clear about the test technology requirements of the creep test machine? I hope the above article can be helpful to everyone! If you want to know more detailed information about the test machine, you are welcome to follow our company. This not only provides you with high-quality test machine equipment, but also provides various equipment information to help everyone further understand the equipment. If you have any needs, please come and consult.

Recommended productsPRODUCTS