Plastic transition temperature drop hammer impact test machine

Plastic transition temperature drop hammer impact test machine

Product Description:

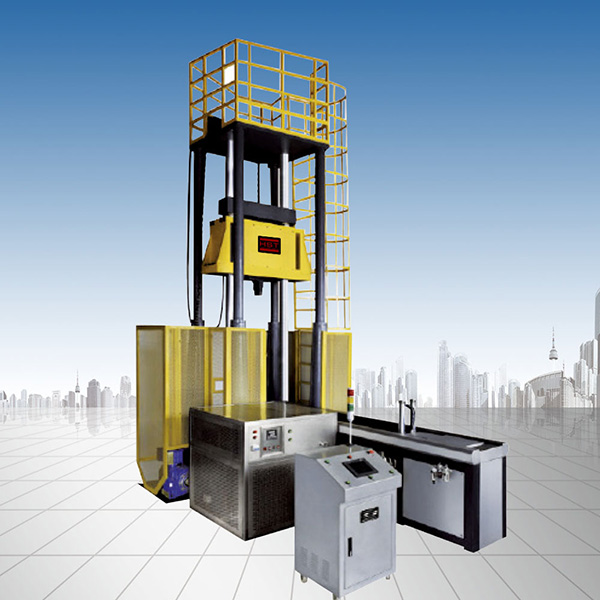

This test machine is suitable for conducting non-plastic transition temperature test of ferrite steel. The non-plastic transition (NDT) temperature refers to the temperature at which the standard sample breaks when tested according to ASTM E208-2006 and GB/T 6803-1986. It characterizes the temperature at which the steel containing cracks undergoes brittle breaking under dynamic loading yield stress.

It consists of a frame, lift, hammer, anvil, safety protection and control system. The machine uses the method of adjusting the amount of counterweight thallium and adjusting the impact height to adjust the impact energy, and has the functions of preventing secondary strikes and automatic sample delivery. The sample is accurately and fast, the energy range is steplessly adjustable, and it has an energy automatic display function.

The test machine can adjust the impact energy by configuring different hammer weights and changing the lifting height. The impact energy can be preset and the lifting height can be controlled.

The test machine is equipped with manual and electric automatic sample delivery and positioning mechanism. The span of the sample support table can be adjusted to meet the span requirements of different samples.

The test machine is provided with a device to prevent secondary impact of the hammer. A safety insurance mechanism and safety protection device are provided.

The test machine can be equipped with a low-temperature device of 40℃~-100℃.

Main technical parameters:

Technical parameters | NDTS-2000 | NDTS-3000 | |

Hammer body of the hammer tester | 60kg (counter weight 15kg/block, 2 blocks in total) | 90kg (counterweight thallium | |

Basic hammer weight | 30kg | 30kg | |

Hammer head quality error | ≤±1% | ||

Counterweight block quality error | ≤±0.5% | ||

The energy of the hammer test strike | 2000J | 3000J | |

The energy range of the strike | 300~2000J | 300~3000J | |

Shock height | 3400mm | ||

Hammer lift speed | 0-3000mm/min (stepless adjustable) | ||

Sample centering accuracy | ±1mm | ||

Hammer punch radius | 25mm | ||

Lift height indication deviation | ≤2mm | ||

Hammer punch radius | 25mm | ||

Hardness of punch, anvil support table and terminator table | >HRC58 | ||

Appearance size | 1100×1100×5200mm | ||

Total equipment power | 50Hz/380V/0.75kW | 50Hz/380V/1.0kW | |

The quality of the whole machine | About 2300kg | About 2600kg | |

- Previous article:Microcomputer-controlled hammer tear tester

- Next article:Non-plastic transition temperature drop hammer impact test machine

Recommended informationNEWS

- [2022-09-28]What should be noted when using the repetitive bending test machine for steel bars?

- [2022-09-28]Main uses and daily maintenance of spring tester

- [2022-09-28]How should the pressure tester be operated and calibrated

- [2022-09-22]How should the pressure tester be operated and calibrated

- [2022-09-09]Performance characteristics of insulator horizontal tensile testing machine

- [2022-09-09]Basic functions of terminal tension testing machine

- [2022-09-09]Operation method and characteristics of cup protrusion test machine

- [2022-09-09]Tear test of various samples by electronic universal testing machine

- [2022-09-09]How to choose the internal structure of the tensile tester

- [2022-09-02]Daily maintenance of test machines

- [2022-09-02]Research and development trends of spring test machines

- [2022-09-02]Working principle of anchor chain tension testing machine

- [2022-08-26]Advantages of universal tensile testing machine

- [2022-08-26]Do you know how important the configuration of the universal tensile test machine is? The configuration of the universal tensile test machine

- [2022-08-26]Introduction to the functions of the repeated bending test machine of metal material

- [2022-08-26]How to use the universal tensile testing machine?

- [2022-08-26]What are the key points of the lateral deformation test of electronic universal testing machines?

- [2022-08-12]Testing method of metal rods by testing machine