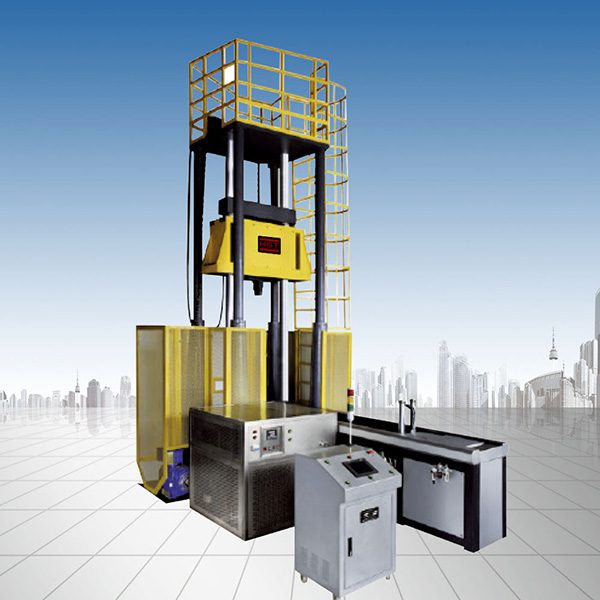

Microcomputer-controlled hammer tear tester

Microcomputer-controlled hammer tear tester

Product Introduction:

This seriesHammer tear testerSuitable for hammer tear impact tests of various ferrite steels, especially various pipeline steels. Comply with GB/T8363-2007 and ASTM E436 test methods. Powerful software analysis function gives various data processing results: preset energy, impact energy, absorption energy, impact speed, impact time, load, energy at load, time at load, deformation at load, load-time waveform, energy-time waveform, and detection reports can be automatically generated, including various test results as well as sample size, grade, number, temperature, ambient temperature and humidity, etc.

By standard:

GB/T8363-2007 "Ferritic Steel Hammer Tearing Test Method".

Reference standards:

(1) API5L3 American Petroleum Society recommends methods;

(2) ASTM E436-80 standard method for dynamic tear test of ferrite steel drop hammer;

(3) ASTM E604-83 Standard method for dynamic tearing of metal materials.

Host system:

1) The main machine system consists of two circular slide columns, four square columns, top plate, base, buffer device, support, jaw, hammer drop, hammer lifting mechanism, hammer lifting mechanism, safety protection device, sample feeding and positioning mechanism, anti-tilt mechanism, etc.

2) The frame is solid and reliable in connection: the slide column and column are perpendicular to the base, which can easily clean and lubricate the slide column; the sample is simple and fast to send and position accurately, and the anti-tilt device is strong and durable, which can reliablely ensure that the sample is not skewed or tilted during the impact, avoiding the sample being twisted and continuously hit at one time; the support and jaws are strong and friction-resistant; the safety insurance mechanism and safety protection net ensure personal safety, reliability and durability; the shock-absorbing buffer device is effective and durable; the hammer hanging and hammer removal mechanism are flexible and reliable.

Specifications and models | JLW-30000 | JLW-40000 | JLW-50000 |

Impact energy | 30000J | 40000J | 50000J |

Lift height | 2500mm | ||

Host installation height | ≤5.8m | ||

Shock speed | ≥5m/s | ||

Support span | 254+1.5mm | ||

Radius of curvature of the hammer blade | R25.4±2.5mm | ||

Radius of curvature of the support jaw | R14.3±1.59mm | ||

Deviation of center line of the hammer blade from the support span center | ±1mm | ||

Rockwell hardness of the bearing surface of hammer blade and support jaw | ≥HRC55 | ||

Sample specifications | 300×70×(6-32)mm | ||

Test machine size | About 1600×2300×5500mm | ||

Recommended informationNEWS

- [2022-09-02]Working principle of anchor chain tension testing machine

- [2022-08-26]Advantages of universal tensile testing machine

- [2022-08-26]Do you know how important the configuration of the universal tensile test machine is? The configuration of the universal tensile test machine

- [2022-08-26]Introduction to the functions of the repeated bending test machine of metal material

- [2022-08-26]How to use the universal tensile testing machine?

- [2022-08-26]What are the key points of the lateral deformation test of electronic universal testing machines?

- [2022-08-12]Testing method of metal rods by testing machine

- [2022-08-12]Electronic universal testing machine-Plastic film tensile testing machine

- [2022-08-04]How to install a clamp to save effort

- [2022-08-04]What are the causes of oil leakage in the universal pressure test machine?

- [2022-08-04]Tension machine

- [2022-07-29]Staff must conduct necessary inspections on the different structures and parts of the fatigue testing machine

- [2022-07-29]In practical applications, friction between parts is inevitable.

- [2022-07-29]Methods to avoid positioning errors of electronic universal test machines

- [2022-07-29]What errors are prone to occur when using the fatigue test machine

- [2022-07-29]Performance characteristics of electronic universal testing machine and preparations before operation

- [2022-07-20]What are the safety and service life of the woven bag tensile tester?

- [2022-07-20]Several categories of tension machine sensors