News

Common faults and solutions encountered by impact test machines

Release time:2019-07-18 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

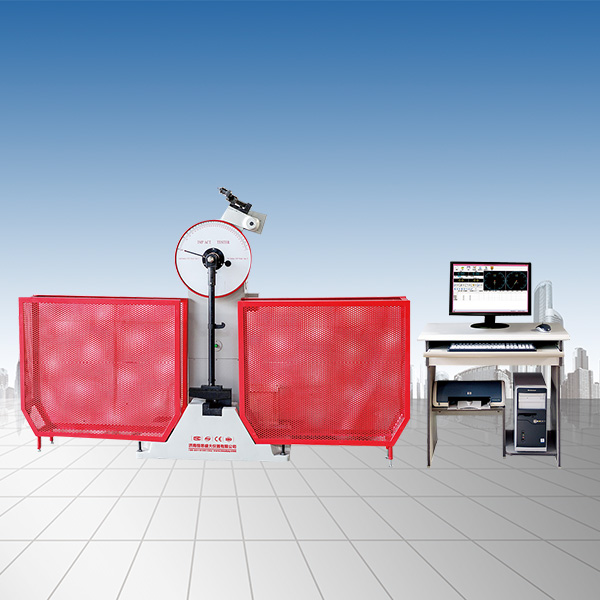

Impact testing machine (English name: impact testing machine) refers to a material testing machine that applies impact testing force to the sample and performs impact testing. The impact testing machine is divided into manual pendulum impact testing machine, semi-automatic impact testing machine, non-metal impact testing machine, etc. It is a new impact testing machine that can instantly measure and record the characteristic curves of materials during impact. By replacing the pendulum and the sample base, two types of tests can be achieved: simple support beam and cantilever beam can be achieved. It detects angular displacement signals and sends them to the computer for data processing, with high accuracy.

If the impact tester is used for too long, some common faults will occur. Today, I will explain to you about the common faults encountered by impact tester and solutions.

1. Common faults encountered by impact test machines

1. During tensile test, the sample fracture is always broken on both sides.

2. The dial pointer has poor sensitivity, the position of the pendulum is abnormal, and the swing rod of the impact tester is not marked vertically.

3. The impact test machine hammer returns to position abnormally, sometimes fast and sometimes slow. The passive needle cannot stop well in any position and does not coincide with the main needle.

4. When loading, the oil circuit system will have serious oil leakage or the oil pipe will be broken.

5. After the sample breaks, the pendulum quickly falls back, causing an impact.

2. Under normal circumstances, the solution to the failure of the impact tester is:

1. If the jaws are not placed in a straight position when clamping, the jaws should be clamped symmetrically as required.

2. The jaws are of poor quality and damage to the teeth. In addition to affecting the jaws, the sample is slipped during the test, making it difficult to identify the yield point. The jaws should be replaced at this time.

3. The lifting guide wheel is not adjusted properly, so that the upper and lower jaws are not centered. A test rod should be processed, and after the upper and lower jaws are tightened, use a dial gauge to measure with two force columns until the adjustment is qualified. Replace oil with appropriate viscosity. Check whether the joints of the oil circuit system are tightened. If you need to replace the gasket, replace it in time. If the oil pipe is broken, check whether the joints of the oil circuit system are tightened. If you need to replace the gasket, replace it in time. If the oil pipe is broken, then the oil pipe with higher strength needs to be replaced. In addition, you must observe whether the oil supply valve and relief valve piston are pressed to death or are installed in reverse. Common faults: After the sample breaks, the pendulum quickly falls back, causing an impact.

The above are common faults and solutions encountered by impact testing machines that you have shared with you. I hope they can be helpful to you. In short, you should pay attention to the problems found during use of the testing machine and promptly eliminate them to avoid errors in your test results. It is to regularly check and correct the test machine to ensure the normal use of the test machine.

Strategy Center - 2+8 Application Scenarios (Part 2)Recommended productsPRODUCTS