News

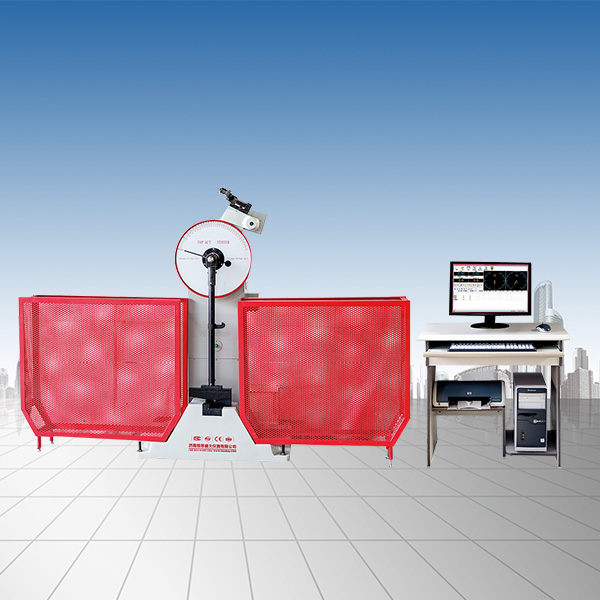

Advanced and performance characteristics of manhole cover pressure fatigue testing machine

Release time:2019-08-06 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The manhole cover pressure tester uses a microcomputer to display, drive the hydraulic cylinder and load sensor to detect the test force of the test piece. Stable and reliable performance, accurate data detection. So do you know the advanced and performance characteristics of manhole cover pressure fatigue testing machines? Let’s take a look with the editor.

1. Advanced nature of manhole cover pressure fatigue testing machine

1. The manhole cover pressure fatigue tester adopts newer technologies in the 21st century in hardware design, reducing the number of printed board-level devices by 3-10 times (compared with domestic and foreign peers), and improving theoretical reliability by more than 5 times;

2. A direct digital control drive system implemented with a high-speed processor enables the speed regulation and change ratio to 500,000 times (0.001mm/min - 500 mm/min), synchronizing with the international higher level;

3. Four-quadrant acquisition of optoelectronic encoders using high-speed processors solves the problems that plague the domestic test machine industry;

4. The modular multi-level structure software system enables the software to go beyond the laboratory level of its domestic peers and achieve product-level reliability and compatibility;

2. Performance characteristics of manhole cover pressure fatigue testing machine

1. The manhole cover pressure fatigue testing machine has the advantages of flexible operation, slow and stable loading, and strong load-bearing capacity;

2. Pure digital phase-locked loop position pulse control mode, no zero float, no offset;

3. The high-precision ball screw secondary transmission loading has the characteristics of stable loading, long service life, good stability and energy saving;

4. Measures such as overloading, overdisplacement protection, and forced mechanical safety limit protection of software parts;

5. The manhole cover pressure fatigue tester software system is simple, reliable and powerful human-computer dialogue user operation interface

6. An open data structure, whether it is result parameters or process data, allows users to call randomly, which is very beneficial to scientific research and teaching.

7. The manhole cover pressure fatigue test machine adopts a high-precision, fully digital speed regulation system and precision reducer;

8. Drive the precision lead screw pair for testing to achieve large-scale adjustment of the test speed, low noise and stable operation during the test process.

9. Touch key operation method, LCD display in real time;

10. Test method selection interface, test parameter selection interface, test operation and result display interface and curve display interface, which is convenient and fast;

11. The manhole cover pressure fatigue test machine realizes the adjustment of the fast and slow lifting of the cross beam during sample clamping, and has functions such as overload protection.

12. Microcomputer interface, which can be connected to external microcomputer to realize the control of the test process and the storage and printing of data.

13. The manhole cover pressure fatigue test machine has low noise, no oil pollution, and is flexible, convenient and reliable in use.

The manhole cover pressure fatigue test machine is suitable for test pieces with a bearing capacity of more than 20kN and no more than 1000kN. It complies with the national GT/T2611 "General Technical Conditions of Test Machines" and the national metrological verification regulations JJG139 "Tenering, Pressure and Universal Test Machines" standards. The above is the relevant introduction to the advanced and performance characteristics of manhole cover pressure fatigue testing machines introduced to you by the editor. I hope it can help you.

The original intention of design of global marketing- Previous article:Functions and main parameters of tensile testing machine

- Next article:Introduction and maintenance methods of shear testing machine

Recommended productsPRODUCTS