News

Introduction and maintenance methods of shear testing machine

Release time:2019-08-07 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

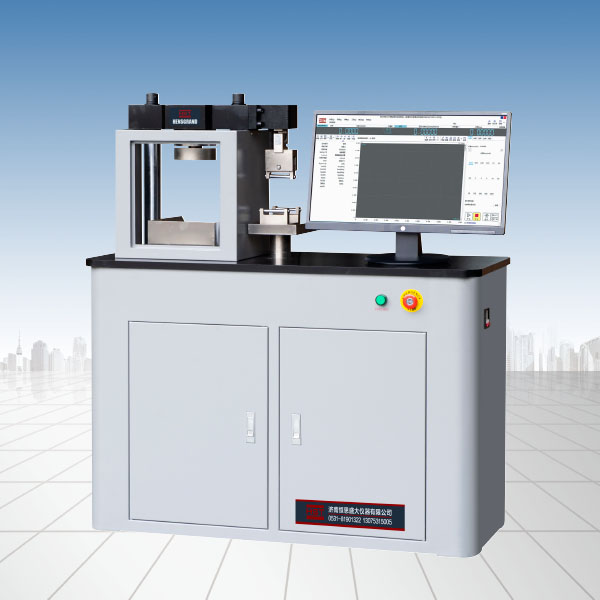

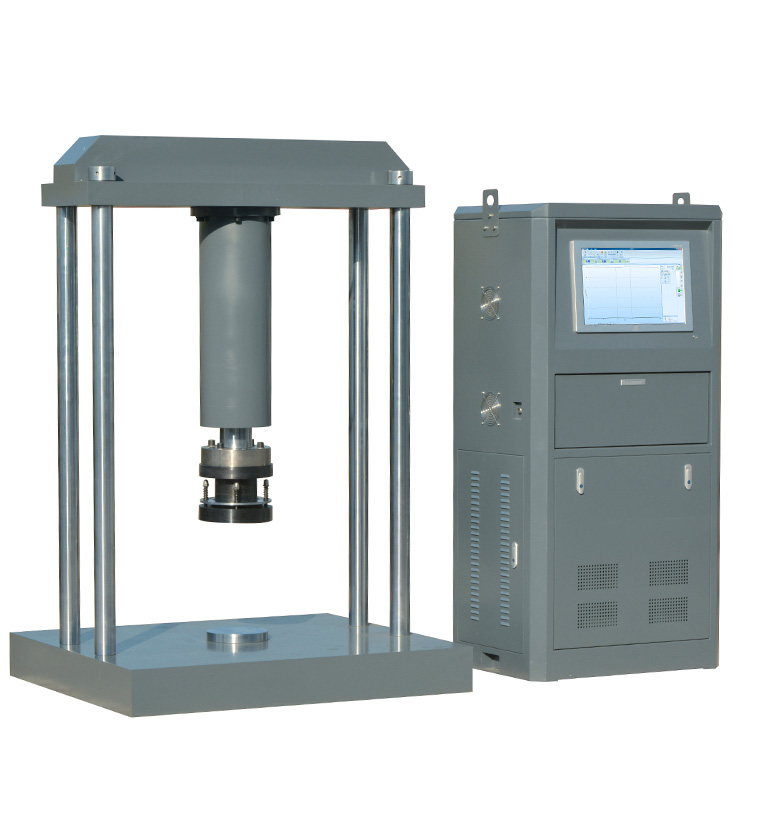

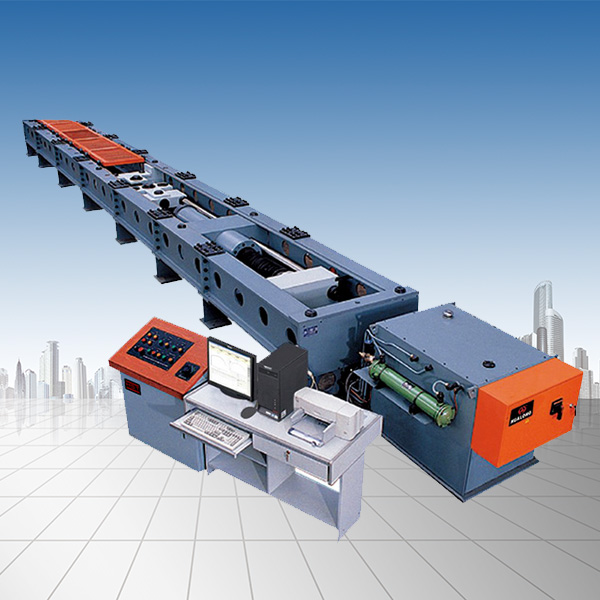

The compression shear test machine is mainly used to test the axial radial compression, shear and angular mechanics of the rubber bearing under the composite conditions of various bridge plate-type and basin-type rubber bearings. Today, the editor will tell you about the introduction and maintenance methods of the press shear testing machine, so that you can further understand this equipment.

1. Introduction to the shear test machine

1. Turn on the main power supply of the laboratory and turn on the control table power;

2. Start the computer and run the MaxTest test machine control program;

3. Press the oil pump button to start the oil pump;

4. Wait for the green oil pump lamp to light up, press the high-pressure button to start the high-pressure;

5. Rotate the pressure adjustment knob on the control table and adjust the pressure to about 3MPa;

6. Before starting the sample transport cart, be sure to drop the main oil cylinder and corner oil cylinder to the lowest position and adjust the system pressure to about 3MPa.

7. Test ends

a. Rotate the pressure adjustment knob on the control table and adjust the pressure to about 3MPa;

b. Operate the compression program, drag the slider to -100%, press the "Start" button to control the main cylinder piston to fall to the bottom, and press the "Stop" button. Then drop the corner cylinder piston to the bottom.

8. Shut down

a. Rotate the pressure adjustment knob on the control table to minimize the pressure;

b. Close high-voltage button;

c. Close the oil pump button

d. Close the software and exit the Windows system.

e. Close the main power supply.

9. After the test is completed, the test site should be cleaned and hygienic, wiped and maintained the test machine, and carefully filled in the machine usage records.

2. Basic maintenance work content of the press shear tester

First, if you want to maintain the later use of the equipment, you should pay special attention to it during installation, because the installation environment and use environment will directly affect the later operation and cleaning and maintenance operations. If you want to make the follow-up work go smoothly, you need to consider multiple factors when choosing an installation environment.

Second, because merchants in different fields use press shear testing machines in different fields, and the operating environment is different, the use of this type of equipment is also different. However, the components of each part of the testing machine equipment should be checked regularly, especially to ensure that the key components do not have fault problems or severe wear. If such problems are found, replacement measures must be taken immediately, otherwise it may affect the final inspection operation.

Third, oil leakage is also common during the use of the press shear test machine. Everyone should check the seal ring and related accessories regularly. If you find that the seal ring is not sealed firmly, you should go to the original manufacturer to buy the same type of seal ring for replacement.

Fourth, the connecting wires on the back panel of the press shear tester are often ignored by everyone, but problems are prone to occur, such as breakage, poor contact, reduced insulation performance, etc. Everyone should take corresponding protective measures for this type of connecting wire to ensure that it will not be bitten by mice or the insulation performance will be reduced due to moisture.

Fifth, for the cleaning of this type of equipment, you can combine professional detergent products and use tools that meet the standards to work together, especially for the jaw part. During the cleaning process, it is necessary to pay attention to its wear level. If the jaw wear level is serious, corresponding solutions should be taken.

Sixth, after each maintenance, staff need to use text to record the overall situation of the shearing test machine, so as to facilitate inquiries about the problem in the future.

The above is the introduction and maintenance method of the press shear testing machine compiled by the editor. I believe that after reading it, you will have an understanding of this. In short, you should pay attention to the problems found during use of the testing machine and promptly eliminate them to avoid errors in your test results. It is to regularly check and correct the test machine to ensure the normal use of the test machine.

A trilogy of global marketing driving brand growth (III)Recommended productsPRODUCTS