News

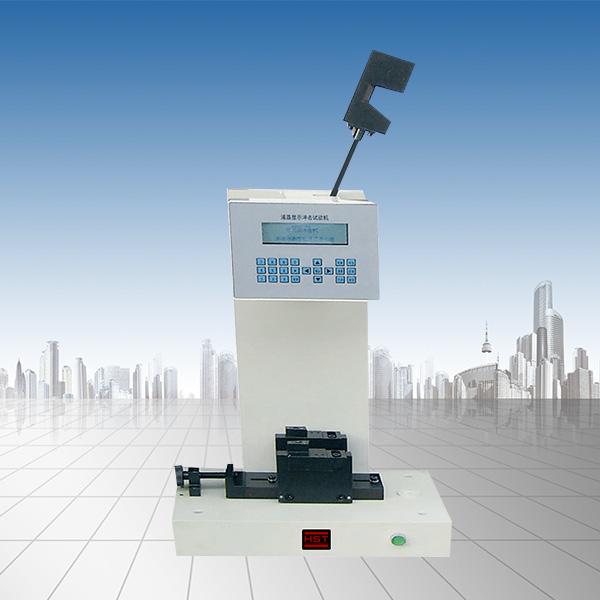

Calibration method and maintenance of steel bar bending test machine

Release time:2019-08-08 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The steel bar bending test machine is a special equipment for cold bending tests and plane reverse bending tests on steel bars. Its main technical parameters comply with the provisions and requirements of cold bending tests and plane reverse bending tests in GB1499.2-2007 "Steel Pipes for Reinforced Concrete Part 2: Hot Rolled Ribbed Reinforced Bars" and YB/T5126-2003 "Standard Plane Reverse Bending Test Plan" and ISO10065:1900 on Cold Bending Tests and Plane Reverse Bending Tests. Let’s introduce the calibration method and maintenance of the steel bending test machine.

1. Calibration method of steel bar bending test machine

1. Visually test whether the inner wall of the wire eye is smooth, and whether it is smooth and straight before and after touching with your hands.

2. Check whether the steel bar bending test machine and the pedestal are firmly fixed. The shaking handle can swing freely on the left and right 900, such as whether the jaws and wire eye are easy to load and unload, and it will be loose enough after being tightened.

3. Use a steel ruler to measure the length, width and height of each part.

4. Which vernier caliper should be used to measure the inner diameter of each wire eye.

2. Maintenance of steel bar bending test machine:

1. Before starting the machine, lubrication should be carried out according to the specified lubrication parts and lubrication methods.

2. It is not allowed to bend large steel bars with small diameters.

3. Disassemble and assemble by professionals who understand the structure of this test machine

4. When the steel bar bending test machine is deactivated for a long time, anti-rust oil should be applied to the working surface and stored in a dry place.

5. Keep the test machine clean

6. Do not disassemble and assemble integrated circuits and printing boards live, otherwise it will easily damage electronic originals.

7. The shell of the steel bending tester should be reliably grounded

8. Manual control adjustment operation should avoid intermittent operation, otherwise it will affect the service life of the equipment. Operation as much as possible is done to reduce the number of manual rotations.

After reading the calibration method and maintenance of the steel bending test machine, do you know about this? I hope this sharing can help you. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer it one by one. Welcome to call and support!

Global Marketing Overview- Previous article:Introduction and maintenance methods of shear testing machine

- Next article:Use and maintenance of peeling force tester

Recommended productsPRODUCTS