The eddy current coating thickness gauge is the crystallization of high-tech technology. It adopts microcontroller technology, with high accuracy, digital display, stable display, low power consumption, simple and convenient operation, no correction knob, single probe full range measurement, small size and light weight; it also has storage, readout, low voltage indication, and its performance reaches the advanced level of contemporary international similar instruments. What is the working principle of the vortex coating thickness gauge? If you want to give full play to the unique characteristics of the equipment during use, then users must carefully understand the various knowledge points of the equipment. How much do you know about the working principle of the vortex coating thickness gauge?

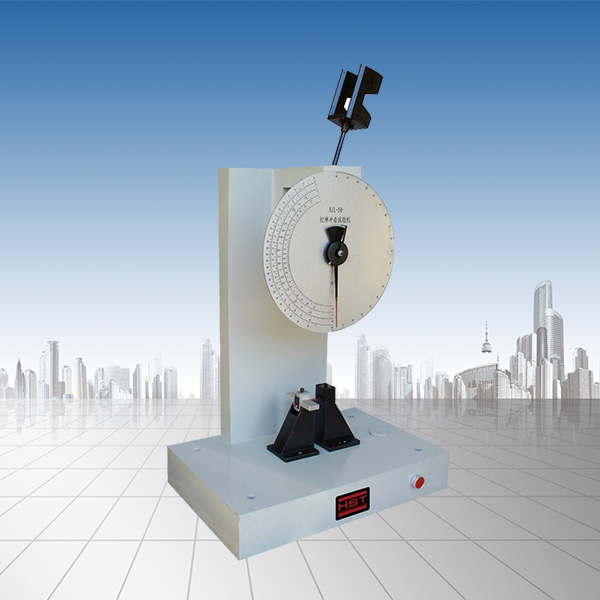

![How much do you know about the working principle of the vortex coating thickness gauge - [Information]](http://www.hssdtest.com/uploads/image/20250418/34/c9c01a7e995dbee2f5364a29c725d1cf.jpg)

1. Working principle of vortex coating thickness gauge

The basic working principle of the eddy current coating thickness gauge is that when the probe contacts the measured pattern, the high-frequency electromagnetic field generated by the probe device causes the metal conductor placed under the probe to generate eddy current, and its amplitude and phase are a function of the thickness of the non-conductive cover layer between the conductor and the probe. That is, the alternating electromagnetic field generated by the eddy current will change the probe parameters, and the size of the probe parameter variable, and the electrical signal is converted to obtain the thickness of the measured coating.

2. Reasons affecting the measurement accuracy of the eddy current coating thickness gauge

(1) When the thickness of the cover layer is greater than 25μm, its error is approximately proportional to the thickness of the cover layer;

(2) The conductivity of the matrix metal has an impact on measurement, and it is related to the composition of the matrix metal material and heat treatment method;

(3) Any thickness gauge requires that the base metal has a critical thickness. Only when it is greater than this thickness can the measurement not be affected by the base metal thickness;

(4) The eddy current thickness gauge has an edge effect on the pattern measurement, that is, the measurements near the edge of the pattern or the inner corner are unreliable.

(5) The curvature of the sample has an impact on the measurement, and this effect will significantly increase with the decrease of the radius of curvature;

(6) The surface roughness of the matrix metal and cover layer affects the measurement accuracy, and the roughness increases, and the impact increases;

(7) The eddy current thickness gauge is sensitive to adhesion substances that hinder the close contact between the probe and the surface of the cover layer. Therefore, dirt on the probe and the surface of the cover layer should be removed before measurement; during measurement, the probe and the test surface should be kept in vertical contact with the constant pressure;

The above is about the working principle of the vortex coating thickness gauge, and how much do you know about it. I hope this article can help you. Friendly reminder: If you have any unclear areas, please call us for consultation. Our company is a modern high-tech company focusing on R&D, design, production and sales of test equipment, with a variety of machines for you to choose from!

Alibaba's Double 11 consumer asset list is here, which largely reveals the subsequent industry competition landscape

![How much do you know about the working principle of the vortex coating thickness gauge - [Information]](http://www.hssdtest.com/uploads/image/20250418/34/c9c01a7e995dbee2f5364a29c725d1cf.jpg)