News

Do you know the operation process and precautions of the steel bar bending test machine? [Information]

Release time:2019-08-21 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

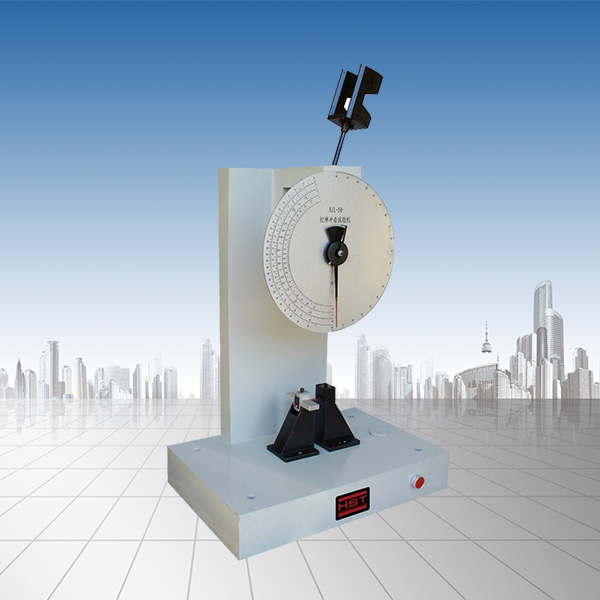

The steel bar bending test machine is a special equipment for cold bending tests and plane reverse bending tests on steel bars. Its main technical parameters comply with the provisions and requirements of cold bending tests and plane reverse bending tests in GB1499.2-2007 "Steel Pipes for Reinforced Concrete Part 2: Hot Rolled Ribbed Reinforced Bars" and YB/T5126-2003 "Standard Plane Reverse Bending Test Plan" and ISO10065:1900 on Cold Bending Tests and Plane Reverse Bending Tests. So do you know the operating procedures and precautions of the steel bar bending test machine? Let’s take a look with the editor.

![Do you know the operation process and precautions of the steel bar bending test machine? [Information]](http://www.hssdtest.com/uploads/image/20250418/87/5d36d97c996dbf3d19746a4d350a8e76.jpg)

1. Operation process of steel bar bending test machine:

1. Before starting the machine, check whether the equipment parts are normal and whether the power supply is stable;

2. Adjust the center distance of the pressure bearing roll according to the sample specifications and test requirements;

3. Choose the diameter of the bent center (press rolling) according to the requirements, install the bent center on the piston rod. The screws must be tightened at all places when connecting, but ensure that the bent center axis is plumb;

4. Place the sample inside the pressure bearing roller and roll close to the pressure bearing roller. Turn the electrical switch on the panel, start the oil pump motor, and the oil pump starts supplying oil. Turn the handle of the manual reversing valve to the left, advance the piston rod with the bent center, and bending the sample until the sample deformation reaches the specified amount, and then turn the handle back to the middle position (plumb state). At this point, all bending tests of the specimen have been completed.

5. Turn off the electrical switch, stop the oil pump, and cut off the power supply. Remove the center and connection block so that the piston rod does not bear additional load.

![Do you know the operation process and precautions of the steel bar bending test machine? [Information]](http://www.hssdtest.com/uploads/image/20250418/32/98f05965f96d020f1614f3d67bf85dd0.jpg)

2. Things to note about the reinforcement bending test machine:

1. Check whether the mechanical performance is good, the workbench and bending machine table are kept level; and prepare various mandrel tool barriers.

2. Install the mandrel, forming shaft, iron stop shaft or variable stop frame according to the diameter of the processing steel bar and the requirements of the bending machine. The diameter of the mandrel should be 2.5 times the diameter of the steel bar.

3. Check the mandrel shaft on the steel bending test machine. The stopper and turntable should be free of damage or cracks. The protective cover is securely tightened and reliable. Only after the air machine is running normally can it be operated.

4. During operation, insert one end of the steel bar that needs to be bent into the gap provided by the rotary wheel fixing, and fix the other end close to the fuselage and press it tightly with your hands. Check that the fuselage is fixed and can be installed on the side that blocks the steel bar before it can be activated.

5. It is strictly forbidden to replace the mandrel, change the angle, speed adjustment and other operations during operation, and no refueling or clearing is allowed.

6. When the steel bar bending test machine bends steel bars, it is strictly forbidden to process steel bar diameter, number of roots and speeds beyond the specified machinery.

7. When bending high hardness or low alloy steel bars, the maximum limit diameter should be changed according to the mechanical nameplate regulations and the corresponding mandrel should be replaced.

8. It is strictly forbidden for the steel bar bending test machine to stand in the working radius of the bent steel bar and on the fuselage without a fixed side. The bent semi-finished products should be stacked neatly and the hooks should not be facing upwards.

9. When the turntable is changed, it must be performed after a steady stop.

After understanding the operating procedures and precautions of the steel bar bending test machine, remind the operator to use it in accordance with the procedures and regulations of the instructions when using the test machine. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. Hope this introduction can help you.

Publicis Group and Alibaba deepen their global cooperation strategy to start "cloud marketing"Recommended productsPRODUCTS