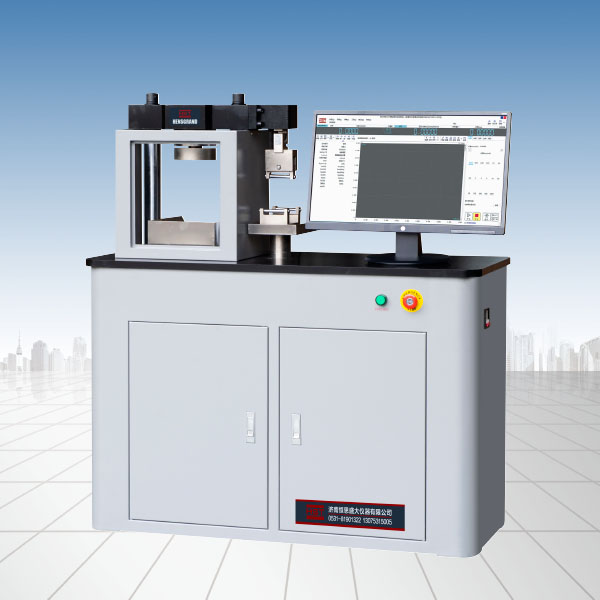

Fatigue testing machine is a machine used to test the fatigue characteristics and fatigue life of various materials such as metals, alloys, rubbers, and plastics at normal temperatures. During use, the fatigue testing machine needs to follow certain operating specifications to ensure the accuracy of the test data. Below our technicians will tell you to standardize the operation of fatigue testing machines to ensure the accuracy of the test.

First, the tester must turn on the computer power supply, turn on the test control program of the fatigue test machine, and then turn on the power supply of the control box to preheat the control box of the fatigue test machine equipment, and keep the preheating time for about 30 minutes.

Next, we will enter the formal experimental process. First establish a test data record volume, and then set relevant test parameters for the test materials and corresponding test requirements. In order to ensure the safety of the test, corresponding protection parameters are also required.

Then put the material into the test clip, adjust the gear speed, then adjust the number of dynamic and static loads and clear the number of cycles, and then start the fatigue test machine for the test operation.

After the entire test operation is completed, the power supply of the fatigue test machine control box should be turned off first, then the power supply of the computer should be turned off, and finally other equipment and the total power supply in the entire test area should be turned off to prevent long-term power on and accelerate the aging speed of the wires.

It should also be noted that during the dynamic load loading of the fatigue test machine, the tester should pay attention to the output power of the equipment and the display data of the ammeter at all times. When the equipment meets the requirements of dynamic load, the load capacity is slightly relaxed to ensure the normal progress of the test.

During the process of testing materials, it is very important to set the safety protection and setting up the fatigue test machine. In addition to setting the corresponding safety factor, you should also pay attention to changes in the monitoring data of the computer at the time to determine whether the test material has reached excessive fatigue and is about to break, so as to implement corresponding protection measures on the equipment.

Staff entering the material testing site need to wear corresponding protective supplies in accordance with regulations to ensure the personal safety of the people present. It is also necessary to pay attention to frequently inspecting and maintaining the fatigue testing machine, cleaning the appearance of the equipment, and replacing the screws, lubricating oil, etc. in any problematic situations.

The above is the content of standardizing the operation of the fatigue testing machine and ensuring the accuracy of the test. The fatigue testing machine provides data support for various materials for industrial production and also provides certain data support for scientific research. Therefore, during use, you should pay attention to operating specifications and maintenance measures to ensure the accuracy of the test data and ensure the safety and reliability of the test process.

Alibaba and Kantar release the world's first full-link brand building KPI system