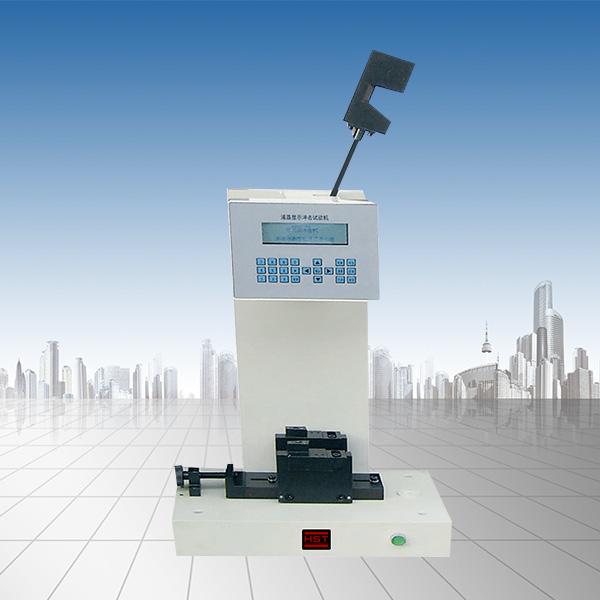

The electronic universal testing machine is the product of the combination of modern electronic technology and mechanical transmission technology. It consists of a measurement system, a drive system, a control system, and a computer structure. A large-scale precision testing instrument composed of mechanical and electrical specialties can carry out a variety of performance tests such as tensile, compression, and bending on various materials, and has the characteristics of wide measurement range, high accuracy and fast response. Reliable work and high efficiency. The connection of the hydraulic system is an indispensable part of the use of the electronic universal testing machine. Let’s introduce the connection and maintenance precautions of the hydraulic system of the electronic universal testing machine. The connection method is as follows:

![Notes on connection and maintenance of hydraulic system of electronic universal testing machine [Information]](http://www.hssdtest.com/uploads/image/20250418/32/58fcca1ae68304edea8c40da87001e70.jpg)

1. First remove the bundlings from each part of the hydraulic universal tensile tester, and use clean kerosene to clean the inside of the oil pipe, especially the threaded threads of the connecting ports of each oil pipe. Check whether the washer at the joint is complete. If it is damaged, use the new washer included in the test machine to prevent oil leakage during high pressure.

2. Staff should use appropriate wrench to connect each oil pipe. If it is a seamless copper pipe, they should be connected to the host and rely on the movement of the console to adjust the spacing to connect to the console end.

3. Uncover the iron door of the hydraulic control box and you can see the wire mesh oil filter. When filling the oil, it is poured into the oil tank through this oil filter. The test machine usually uses hydraulic oil. Hydraulic oil with higher viscosity should be used in summer. In winter, the temperature is low, and it is recommended to use hydraulic oil with lower viscosity.

4. The electronic universal test engine oil volume is too small. The test machine cannot work normally. Too much oil volume will cause hydraulic oil to leak from the working cylinder port. Therefore, be sure to pay attention to the oil level when refueling.

Precautions for repairing electronic universal testing machine

1. When repairing fine instruments, if you accidentally bounce the small parts away, you should start to determine the place where they can fly. Do not look for them or turn them around. You can use magnet scanning and field of view scanning methods to search. When using a logic pen and an oscilloscope to detect signals, be careful not to let the probe touch the two measuring pins, because the essence of this situation is to create a short circuit under power-on condition. In order to better understand the parameters and forms of key points in the use of universal tensile testing machines, the software pioneer specially designed a set of software that can correctly adjust the process and control the production.

2. Please be careful not to plug and unplug all kinds of control boards and plugs with electricity.

3. When checking the internal circuit of the instrument, if the contacts and circuit board of the device components are coated with insulating varnish, when measuring the parameters of each point, you can use a common hand-sewn needle welding on the multimeter's pen to pierce the paint layer and directly measure the points without peeling off the paint layer on a large area.

4. When checking instrument problems in humid conditions, it is necessary to use a multimeter to measure whether the points of the printing circuit can be hysteresis, because the primary problem in this situation is copper foil corrosion. Because when powered on, a strong induced electromotive force will occur when plugging and unplugging the control board, the counterattack voltage will be very high, and it is easy to damage the response control board and plug.

5. Multi-faceted query of data can be conducted, which can enable managers to grasp the trend of quality control and transformation.

Do you know the connection and maintenance precautions for the hydraulic system of the electronic universal tester? Is it helpful to everyone? If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer them one by one. Welcome to call and support!

From e-commerce to new retail, Alibaba CMO Dong Benhong talks about the "no-judgment" of new business changes, from e-commerce to new business changes

![Notes on connection and maintenance of hydraulic system of electronic universal testing machine [Information]](http://www.hssdtest.com/uploads/image/20250418/32/58fcca1ae68304edea8c40da87001e70.jpg)