News

How to use the chip puncher and safety operating procedures

Release time:2019-08-30 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

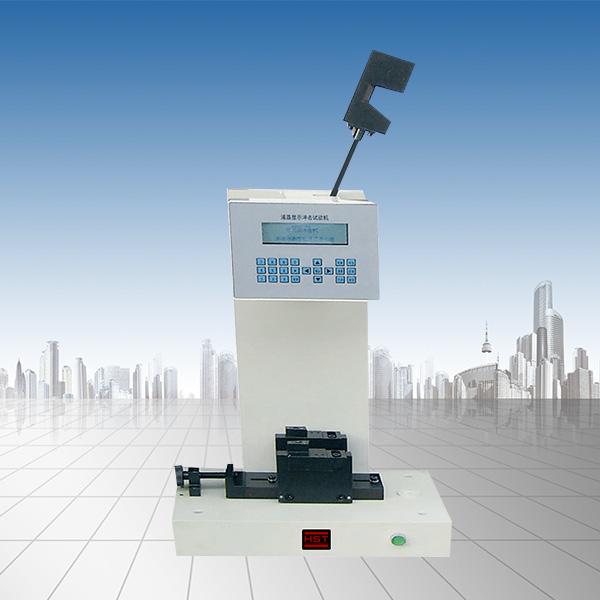

The sheet punching machine provides waterproof materials. Rubber factories and scientific research units conduct standard rubber sheet tests before tensile experiments. The punching machine is used to cut rubber, plastic, leather and other special materials into test pieces specified in various standards for use during testing. It can also be used as a small punch. Below, we will introduce the usage method and safety operating procedures of the chip drill.

1. How to use the chip puncher

1. Place this instrument on a horizontal workbench.

2. Prepare the required samples.

3. On the host platform, place the selected tool vertically below the stamping head.

4. By moving the handwheel behind the machine, the slider is driven by the stamping head to directly apply the pressure on the special molding tool, so that the sample placed on the host platform can be cut off easily, quickly and accurately.

2. Safety operating procedures of chip punching machine

1. The equipment must be responsible for, operate, repair and maintenance;

2. Operators need to conduct safety training and learn the "Instruction Manual" of the chip punching machine, understand the basic structure and performance of the equipment, be proficient in operating procedures, and operate strictly in accordance with operating procedures;

3. The operator of the chip punching machine must wear work clothes, the buttons must be complete and firmly, the sleeves must not be too long, and the work hat must be worn; before the machine starts, the protective equipment and power supply must be checked to be intact and whether there are any abnormalities; before the operation, the chip punching machine manufacturer should turn on the machine and run it out of load for 2 to 3 minutes to confirm that the situation is normal and there is no abnormal noise before it can be put into use; the planer pays attention to personal hygiene, operation hygiene and production hygiene when operating the machine; when the machine is running, it is strictly forbidden to touch the items being processed with your hands;

Before using any test machine, you must fully understand the product's performance and operating procedures so that you can better achieve human-machine running-in during operation. This improves production efficiency. The above is the entire content of the use of the chip puncher and the safety operating procedures. I hope it can help you.

Recommended productsPRODUCTS