News

Basic principles and experimental steps of pipe blasting test machine

Release time:2019-09-04 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

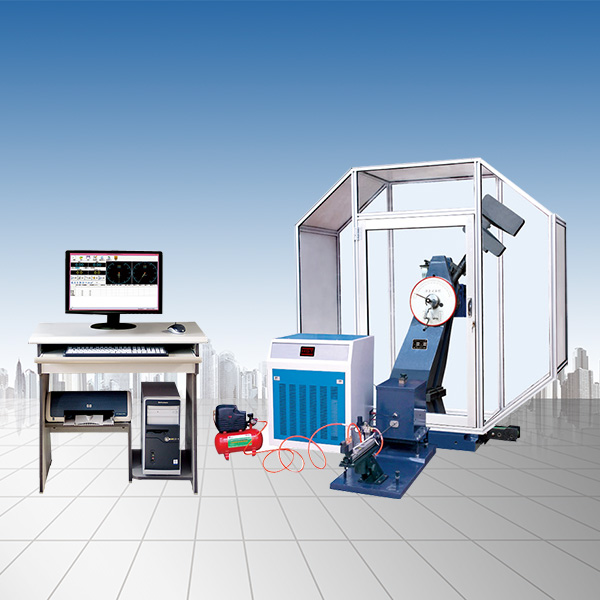

The pipe blasting tester is used to measure the pressure resistance time or the maximum pressure value of instantaneous bursting in thermoplastic pipes, composite pipes (such as PP-R, PP-B, PP-A, PE, PE-X, PVC, PVC-U, PVC-C) and aluminum-plastic composite pipes. The pressure detection display uses a digital pressure gauge, and the time setting is set by an external time relay. Today, let me introduce to you the basic principles and experimental steps of the pipe blasting test machine.

1. Basic principles of pipe blasting test machine:

According to the different temperatures, pressures and ring stresses of the pipe, different parameters are input to the industrial control machine. The high-pressure pump generates high-pressure liquid. Through the pressure control system, it is sent to the sample in the medium constant temperature box by the high-pressure hose, and a long-term hydrostatic test of the pipe is carried out.

2. Test steps of pipe blasting test machine:

1. According to relevant standards, select test types such as water-water test, water-air test or water-other liquid test.

2. Connect the sample after the condition is adjusted to the pressurized device, exhaust the air in the sample, and then apply the test pressure evenly and smoothly to the pressure value calculated according to the formula based on the material, specifications and pressure equipment according to the sample, the test pressure is as short as possible between 30s and 1h, and the pressure deviation is +2-1%. Timing starts when the test pressure is reached.

3. Sleep the sample in a constant temperature controlled environment. The test medium should be kept constant during the entire test process. See relevant standards for the specific temperature. When the constant temperature environment is liquid, keep its average temperature difference at +1℃ and the maximum deviation is +2℃. When the constant temperature environment is an oven, keep its average temperature difference at +3-1℃ and the maximum deviation is +4-2℃, and press 4 or 5 until the end of the test.

4. When the pipe blasting test machine reaches the specified time or the sample is damaged or leaked, the test shall be stopped and the time shall be recorded, except for 5 items. If the sample is damaged, the type of damage should be recorded, whether it is brittle or tough.

Note: In the damage area, if there is no plastic deformation damage, it is "brittle damage", and if there is obvious plastic deformation, it is "tough damage".

If the test has been conducted for more than 1000 hours and the equipment fails during the test, if the equipment can recover within 3 days, the test can continue. If the equipment fails, the test pressure will be maintained through a solenoid valve or other methods. Even if the equipment fails more than the above provisions, the test can continue; but in this case, due to the continuous creep of the sample, the test pressure will gradually drop, and the period when the equipment fails should not be included in the test time.

5. If the sample is damaged at a distance of less than 0.1L0, the test result is invalid. The sample should be taken for retesting (L0 is the free length of the sample).

Before using any test machine, everyone should have a good understanding of the product to better achieve human-machine running-in during operation. This improves production efficiency. The above are the basic principles and experimental steps of the pipe blasting test machine. Friendly reminder: If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation!

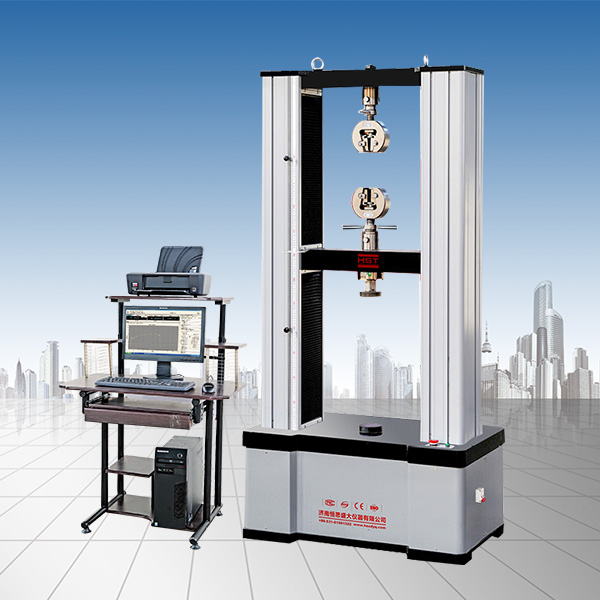

Recommended productsPRODUCTS