News

Components and safe use methods of hydraulic universal testing machine

Release time:2019-09-12 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

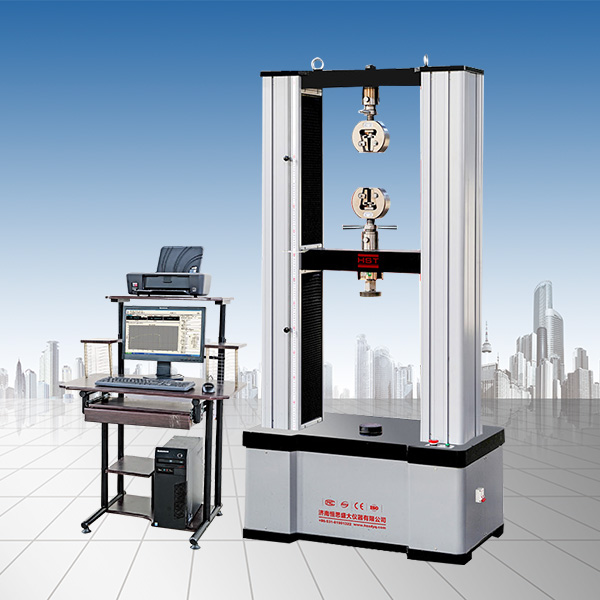

Hydraulic universal testing machine is a hydraulic material testing machine that can perform various tests such as tensile, compression, and bending. Hydraulic universal testing machine is used for tensile, compression, bending and shear tests of various metals and non-metallic materials, as well as special tests of some products. How much do you know about hydraulic universal testing machine? The following editor will introduce to you the components and safe use of hydraulic universal testing machine.

1. The main components of hydraulic universal testing machine

1. Main unit: consists of oil cylinder, base, column, working piston, workbench, sample clamping, up and down movement measurement and movable beam, etc. The main function is to tighten and fix the sample by the sample clamping structure to load the sample.

2. Detection part: It consists of an electronic extensometer, a load sensor (pressure sensor), photoelectric coding, etc., and its main function is to detect the test force, the displacement of motion measured and deformation of the test object.

3. Hydraulic control: It is mainly composed of high-pressure oil pump, oil tank, oil return valve, oil supply valve, shut-off valve, electro-hydraulic proportional valve, working piston, force measuring cylinder piston and working oil tank of the main machine. Its main function is to control the loading of the specimen and the tightening of the specimen.

4. Electrical part: It consists of various relays, switch buttons and AC contactors. Its main functions are to control the action of the beam lifting mechanism, switches of the oil pump motor, various limits and overload protection, etc.

5. Data acquisition and processing and control part: consists of control circuits, data acquisition and processing, printers, computer software and hardware systems, manual control devices, etc. The main functions are the setting, display of various parameters, control of the entire system, recording of test processes and results, processing of data, storage, output of test results, etc.

6. Accessories: It consists of bending test accessories, tensile and compression test fixtures, as well as some other special test accessories such as jaws, chucks, etc. The basic function is to complete various specific tests by replacing the fixtures.

2. Safety method of hydraulic universal testing machine

1. The layout of the electro-hydraulic servo hydraulic universal testing machine should be reasonable, and it should be convenient for operators to load, unload, observe and remove debris; it should also be convenient for maintenance personnel to inspect and repair.

2. The strength and stiffness of the parts and components of the test machine should meet safety requirements, be installed firmly, and do not cause frequent failures.

3. According to relevant safety requirements, hydraulic universal testing machines must be equipped with reasonable, reliable and safe devices that do not affect operation. For example:

(1) For more dangerous tests, corresponding protective devices such as protective covers should be installed to avoid unnecessary damage.

(2) The speed control system should have protection devices such as overcurrent, overvoltage, and overload, such as emergency stop buttons, so that when dangerous situations occur, the risk will be eliminated due to the role of the protection device and prevent accidents from occurring.

(3) When certain actions require warning or reminding people to pay attention, signal devices or warning signs should be installed. Such sound signals such as electric bells, speakers, buzzers, etc., as well as various lighting signals, various warning signs, etc., are all of this type of safety devices.

(4) Interlocking devices should be installed for certain parts that cannot be reversed in the order of action. That is, a certain action must be performed after the previous action is completed, otherwise it will be impossible to move. This ensures that accidents will not occur due to misunderstandings in the order of actions.

Before using any test machine, everyone should have a good understanding of the product to better achieve human-machine running-in during operation. This improves production efficiency. The above is an introduction to the components and safe use methods of hydraulic universal testing machines. I hope it can be helpful to you.

Recommended productsPRODUCTS