News

Main mechanism and specifications of universal material testing machine

Release time:2019-09-16 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

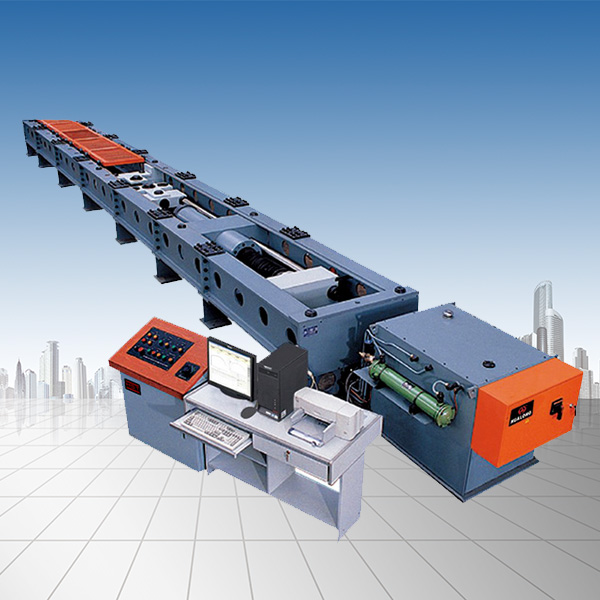

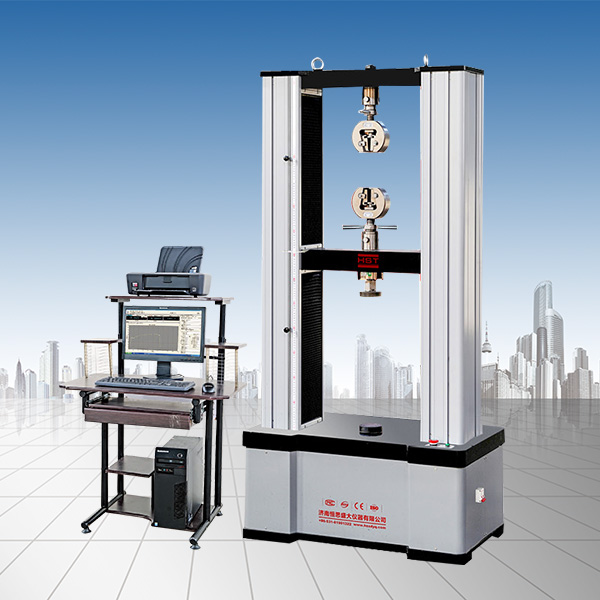

Universal material testing machine is also called universal tension machine or electronic tension machine. Independent servo loading system and high-precision wideband electro-hydraulic servo valve ensure high precision, high efficiency, low noise and fast response of the system; independent hydraulic clamping system is adopted to ensure the system's low noise and smooth operation, and the samples are firmly clamped during the test and do not slip. Let’s introduce the main mechanism and specifications of the universal material testing machine.

1. Main mechanism of universal material testing machine

The universal material testing machine is mainly composed of a bracket, a hydraulic control box, an external force measurement display, and an electrical system. Some of its bodies are measured, such as columns, upper and lower flexural equipment, cylinders, frames, base plates, etc. The measurement surface is installed on the upper right side of the rack. Some hydraulic operations are installed on the lower part on the right side of the frame of the universal data test machine. The lower anti-flexion equipment is installed on the top of the piston. Guide plates are installed on both sides, which can maintain the up and down movement direction of the anti-flexion table. There is a ruler on the flexural table, and guide plates are installed on both sides of the two limits, which can adjust the anti-flexural span at will. The drag roller can move up and down, so that it can play a balanced effect when under the force. The upper anti-flexural equipment is installed under the measurement. The two positioning columns of the turn bolts are fixed under the beam, with a ball head and a ball seat in between. The bolts are equipped with springs to balance the upper anti-flexural equipment, and the drag roller can move up and down. During the flexural resistance test, the universal data test function actively adjusts the orientation according to the appearance of the test piece, so that the arc surface of the indenter is in a straight line with the test piece, ensuring the accuracy of the test. On the oil cylinder and the plane, dustproof coils are installed to prevent or reduce the dust entering between the piston and the oil cylinder when the piston rises and falls, causing both to accelerate wear. During the compression test, as long as you put a pressure pad and a lower pressure plate in the center of the flexural table, and remove the flexural equipment under the beam, you can perform the compression test. A sealing ring is installed between the piston and the oil cylinder to prevent oil from spilling out. There is an annular groove at the top of the cylinder and an oil leakage channel. Through the plastic pipe, the oil overflows back to the oil tank.

2. Main specifications of universal material testing machine

Host specifications: A. High-precision force sensor: 0~10KN 20ton. The force accuracy is within ±0.5. B. Capacity segmentation: Seven gears of the whole process: × 1, × 2, × 5, × 10, × 20, × 50, × 100%. Maximum resolution of the whole process: 1/1000,00 C. Power system: Taiwan frequency converter + AC frequency converter + worm gear and worm reducer + T-type screw. D. Control system: Pulse Command control method is used to make the control more accurate, with a speed control range of 5~250 mm/min. It has fast coarse and slow fine adjustment functions. After testing, it will automatically return to the origin and automatically store it. E. Data transmission method: RS232 transmission F. Display method: UTM107+WIN-XP test software LCD screen display. G. A simple, one-stage and precision seven-stage force linear dual correction system. H. The luxury test interface software can realize fixed speed, positioning and fixed load control modes and multi-order control modes to meet ordinary testing requirements. I. Test space: The test width is about 400 mm (standard specification) and the walking space is 800 mm (excluding fixtures) (standard specification) J. Full displacement: The encoder is 1800 P/R, which improves 4 times the accuracy. The LINE DRIVE encoder has extremely strong anti-interference ability. The displacement analysis is 0.001mm. Small deformation: metal extensometer, analysis 0.001mm (optional) K. Safety device: overload emergency stop device, up and down stroke limit device, leakage automatic power off system, automatic breakpoint shutdown function. M. Manual control method: Manual operation box can be added.

The above is the main mechanism and host specifications of the universal material testing machine. I believe everyone has a certain understanding of this after reading it. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer it one by one. Welcome to call and support!

Recommended productsPRODUCTS