News

Functional characteristics and operating procedures of wire torsion test machine

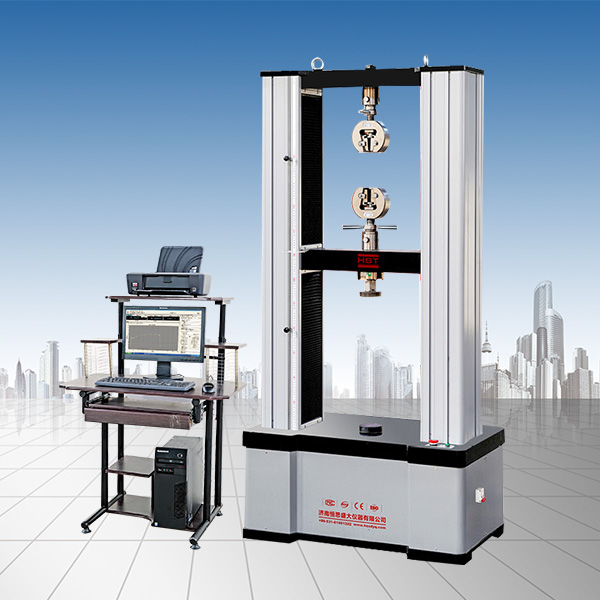

Release time:2019-09-18 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The wire torsion test machine adopts the latest microcomputer controller. The circuit has been specially optimized for the working characteristics of the system, with strong anti-interference performance and stable and reliable work. The display part uses a large-area LCD LCD display with full Chinese characters; the control program is designed according to the principle of humanization, easy to operate, clear display, and accurate results. Let me introduce the functional characteristics and operating procedures of the wire torsion test machine below.

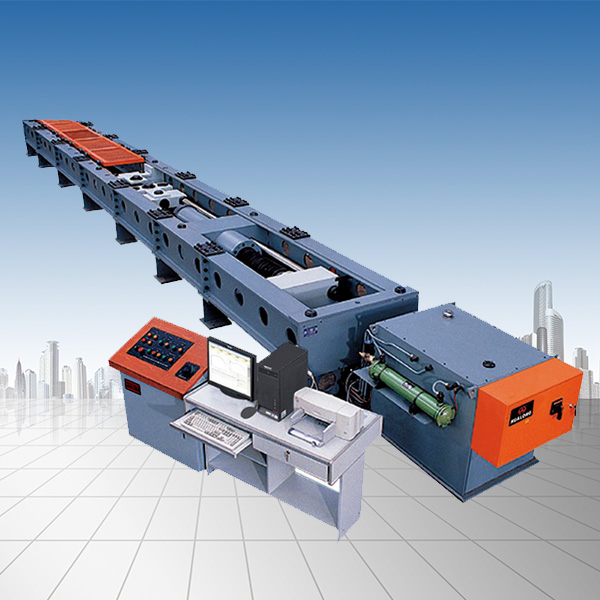

1. Functional characteristics of wire torsion test machine

1. Use computer control, collect, analyze and process experimental data. The test data and curves are displayed dynamically with the test process. The test data is automatically processed and displayed, all completed by the microcomputer. The torque-torque angle (deformation), torque-time curve is drawn, the printer is connected and the test report of the test date, number, material, torsion, strength and other composite national standards is printed. It has functions such as torsion force value and torsion angle automatic tracking measurement, loading speed indication and peak holding;

2. Use a cycloid pin wheel reducer, and the power transmission system is stable and reliable;

3. A torque fine-tuning handwheel is provided to adjust the initial torque to zero;

4. The rack has good rigidity, long-term stability, freely moving workbench, and can be used for samples of different lengths;

5. Equipped with mainstream brand commercial computers as control machines to set test parameters, control working status, data collection, processing and analysis, display and print test results, etc.

2. Operating procedures of wire torsion test machine

1. Check whether the connections of the test machine are normal before the test.

2. Prepare samples and measuring instruments, and select appropriate fixtures and clamps to assemble.

3. Start the computer and printer, and turn on the power supply of the test machine host.

4. Open the test machine measurement and control system software and connect it online. If the online connection is successful, the test LCD screen will display the words "PC control".

5. The wire twist test machine correctly sets the software hardware and software settings and enters environmental parameters.

6. Measure the size of the sample and enter the size information of the sample in the software operation parameter window.

7. First clamp the sample at one end of the sensor, and then clear the torque value in the software. After the torque is cleared, adjust the clip clockwise or counterclockwise

Set a position to clamp the other end of the sample.

8. After tightening the sample, if there is a torque force value. Press the “Mechanical Zero” button in the test machine panel, and then manually rotate the test machine handwheel to zero the torque force value. Press the "Mechanical Zero" button to clear the angle value.

9. The wire twist test machine is equipped with a small angle device to clear the digital display value.

10. In the software's operation parameters window, correctly set the various operation parameters of the test according to the test requirements. 11. Click the Run button and the experiment begins.

12. When the small angle reaches the preset value of the wire twist test machine, please remove the small angle in time to avoid damage.

13. Sample damage, after the test is completed. Output the test results to Excel and print the test report.

14. Remove the damage sample, clean the test bench, and maintain the test environment hygiene.

15. After the test of the wire twisting test machine is completed, turn off the power supply, computer and printer of the test host.

After understanding the functional characteristics and operating procedures of the wire torsion test machine, the operator must use it in accordance with the procedures and regulations of the instructions when using the press. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

Recommended productsPRODUCTS