News

Operation steps and precautions for pressure testing machine

Release time:2019-09-21 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

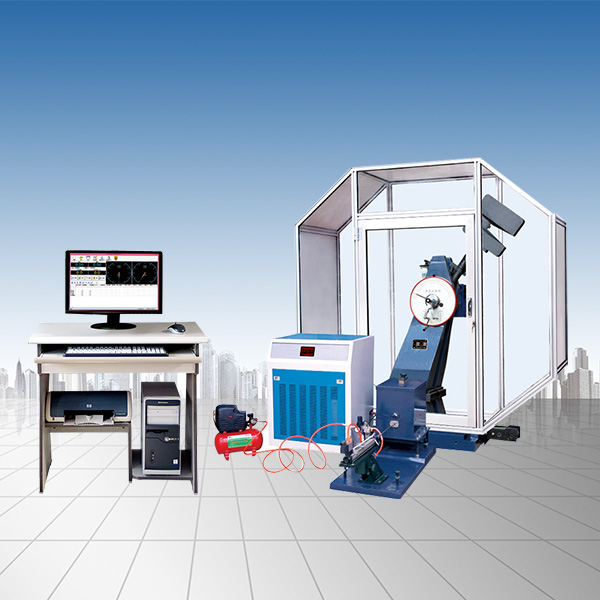

Pressure testing machine, also known as electronic pressure testing machine, is mainly suitable for various physical and mechanical performance testing of rubber, plastic sheets, pipes, special profiles, plastic films, wires and cables, waterproof rolls, metal wires, cartons and other materials. Let’s introduce the operating steps and precautions of pressure testing machine to you. Let’s take a look.

1. Operation steps of pressure test machine

1. Start the motor, close the oil return valve, and unscrew the speed valve handle counterclockwise to supply oil, so that the piston rises and leaves the bottom of the cylinder;

2. Place the test piece, adjust the height of the screw, and adjust it to 1 to 2mm away from the upper pressure plate;

3. The speed valve adjusts to rise rapidly and adjusts the speed valve's rise speed according to the loading speed requirements;

4. After the specimen is broken, open the oil return valve (the speed must be slow when opening the oil return valve) so that the piston falls back. At this time, the reading from the pointer is the damage load of the specimen and it is recorded.

5. Clean the debris of the test piece and conduct the next test. (After the test is completed, press the stop button to turn off the motor and turn off the power supply.)

2. Things to note when using the pressure test machine

1. The test machine is installed in a clean and dry environment with uniform temperature, no vibration around, no influence of corrosive gases and no strong magnetic field interference;

2. The installation and level of the test machine are above the ground and are stable foundation of about 500px higher than the ground. Two anchor bolts should be buried on the basis; the test machine should be confined to the ground;

3. The pressure test machine should be kept clean, and the parts without protective layers should be frequently rubbed oil to prevent corrosion;

4. The rising position of the piston of the test machine must not exceed 80mm. A limit switch is installed on the operating box of the test machine. After the piston rises and hits the limit switch, the motor will automatically stop. The oil return valve should be released immediately and slowly to lower the piston.

Maintenance: The oil should be changed once after half a year of use of the test machine, and the replaced oil must be clean.

Disposal: When there is a problem with the instrument during the test, do not deal with it by yourself. Contact the instrument maintenance personnel in a timely manner and report to the quality person in charge.

After understanding the operating steps and precautions of the pressure test machine, the operator must use it in accordance with the procedures and regulations of the instructions when using the test machine. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation.

Recommended productsPRODUCTS