News

Performance characteristics and precautions for horizontal tensile testing machine

Release time:2019-09-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

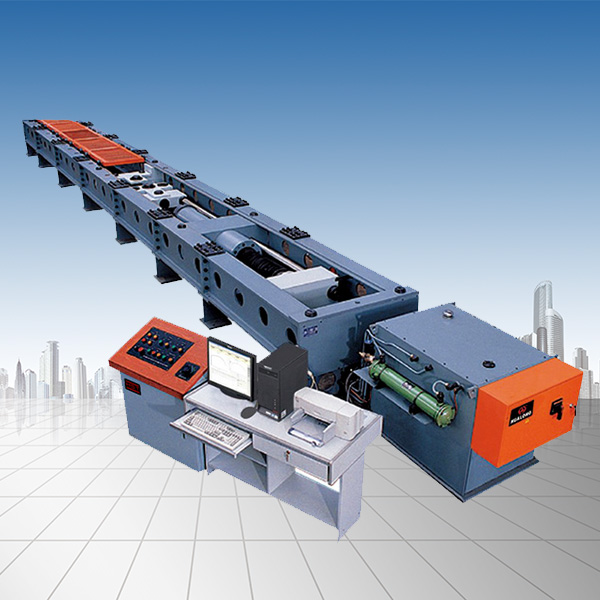

The horizontal tensile test machine adopts mature universal testing machine technology to increase the steel frame structure and change vertical tests into horizontal tests, which increases the tensile space (it can be increased to more than twenty meters, which cannot be done by vertical tests). Today we will introduce to you the performance characteristics and precautions of horizontal tensile testing machines.

1. Performance characteristics of horizontal tensile testing machine

1. Key components adopt internationally renowned brands, such as Panasonic servo system, full-quan load sensor, internal-controlled photoelectric encoder, etc.

2. The arc tooth-shaped synchronous deceleration system has the advantages of high efficiency, long life, low noise and maintenance-free. It adopts purely digital phase-locked loop position pulse control mode, without zero floating and no offset.

3. It uses high-precision ball screw to load, which has a stable loading, a long life of the test machine, good long-term stability and energy-saving.

4. Various protection measures. Such as: various electrical protections in the power link, overloading of the software part, overdisplacement protection, mechanical forced safety limit protection, etc.

5. Simple, reliable and powerful user operation interface.

6. An open data structure, whether it is result parameters or process data, allows users to call it randomly, which is very beneficial to scientific research and teaching.

7. User editing report function. Data can be easily imported into Excel tables, which is convenient for users to process post-processing.

2. Precautions for use of horizontal tensile testing machine

1. Do not click the "Start" test button if the test has not started.

2. Every time you enter the program, if there is an abnormal prompt or the default load value is different from the previous one, do not conduct a test and refer to the troubleshooting method to troubleshoot. The load value of the measurement and control system should be near zero point (not adjusted zero).

3. The horizontal tensile tester uses the cylinder reset key to make the cylinder piston rise or fall to the set position. When the displacement display position value is greater than the set position, the piston will drop when the cylinder reset key is clicked; otherwise, the piston will rise. Pay attention to whether the actual position of the piston is consistent with the displacement display position. Do not blindly use this key to rise or fall when the cylinder is actually in a high position.

4. After clamping the sample, do not "zero" the load value.

5. When clamping the extensometer, pay attention to unplugging the positioning pin and then adjusting the zeroing; when removing the extensometer, pay attention to inserting the positioning pin to prevent the extensometer from being damaged by artificial overload.

6. After the horizontal tensile tester sample is broken, if the program does not exit the test state and prompts that the test is over, you must immediately click the stop button to exit the test state.

7. After completing the test and exit the procedure, you should shut down the power supply by shutting down with WINDOWS; turn off the oil pump and let the oil cylinder fall to the bottom.

8. Be careful not to loosen the plug when moving the computer.

The above is an introduction to the performance characteristics and precautions of the horizontal tensile tester. I believe everyone has a certain understanding of this after reading it. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer it one by one. Welcome to call and support!

Recommended productsPRODUCTS