News

Key points of selection and maintenance of fatigue testing machines

Release time:2019-09-29 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

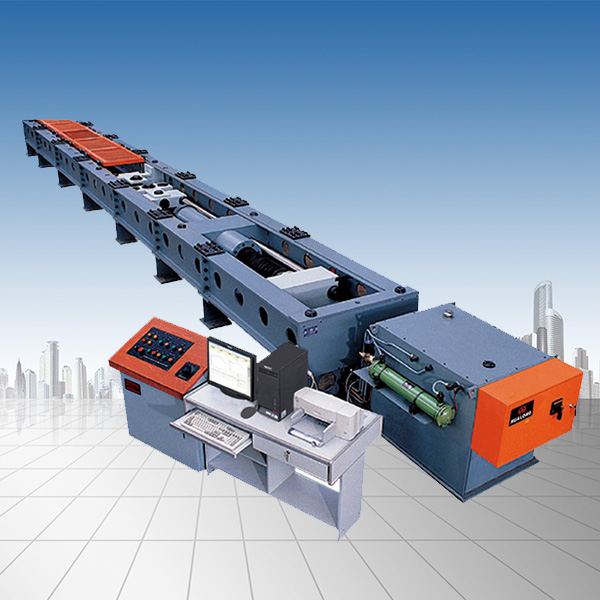

As a detection device, the fatigue testing machine can help us perform relevant inspections better and obtain accurate data. Now many manufacturers are emerging on the market. How can we buy them correctly? The editor will tell you the key points and maintenance of fatigue testing machines. Let’s take a look.

1. Key points for purchasing fatigue testing machines

When choosing fatigue testing machines, some merchants in special fields can follow their actual situations, because the equipment is made with high production technology and has incorporated many high-tech technologies, which is also very critical when designing. You must choose a formal, professional and well-known manufacturer. This not only ensures the performance and quality of the equipment, but also obtains a complete after-sales service.

In addition, it is recommended that you choose based on your existing installation environment and operating conditions. In addition, you should master the data on daily testing standards and installation space size as much as possible, and then negotiate with the manufacturer to select a suitable fatigue testing machine.

The price of fatigue testing machines can be said to be a concern for many consumers. Now, the performance of such equipment launched by different manufacturers on the market not only varies, but also see that the materials, shapes and systems are different. This situation also causes the price of this fatigue testing machine to have different trends. Although the equipment launched by small manufacturers is cheaper, not only is the quality not guaranteed, but it is more likely to cause frequent failures during the later operation process, not only does it require large repair costs, but it may also lead to insufficient data accuracy.

2. Maintenance of fatigue testing machine

First of all, users should conduct a series of inspections on the fatigue testing machine every day before starting and running, so as to ensure that the equipment performs more stably in operation. It is also necessary to check the damage to the parts inside the test machine. If there is severe wear and tear on the internal components, it may also affect the final inspection results.

Secondly, before using this kind of device, you need to read the configuration instruction manual in detail and be familiar with the device structure, button function, and operating system you want to operate. If it is a new equipment you just purchased or a fatigue testing machine that has not been used for a long time, be sure to check whether the insulation resistance of the equipment and the parts are loose, and whether the handles and buttons can be operated and controlled normally.

In addition, after a long period of use, it is necessary to check whether the grounding device is normal, whether the relevant wiring posts are loose, and whether the internal components are severely worn or failed. If you find that the equipment has abnormal noise or short circuit during operation, you must stop running immediately, then perform relevant inspections, and troubleshoot problems before you can continue to use.

This type of equipment cannot be used in flammable and explosive environments, and it cannot work under conditions with corrosive gases. A complete maintenance plan should be formulated according to the frequency of use of the equipment. After the work is completed every day, the equipment must be turned off in accordance with the prescribed requirements before leaving the work site, so as to better extend the service life of the equipment.

To sum up, the following are the introductions to the purchase points and maintenance of fatigue testing machines. I believe everyone has a certain understanding of this after reading it. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer them one by one. Welcome to call and support!

Recommended productsPRODUCTS