News

Requirements for use and maintenance of cement pressure testing machines

Release time:2019-09-30 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

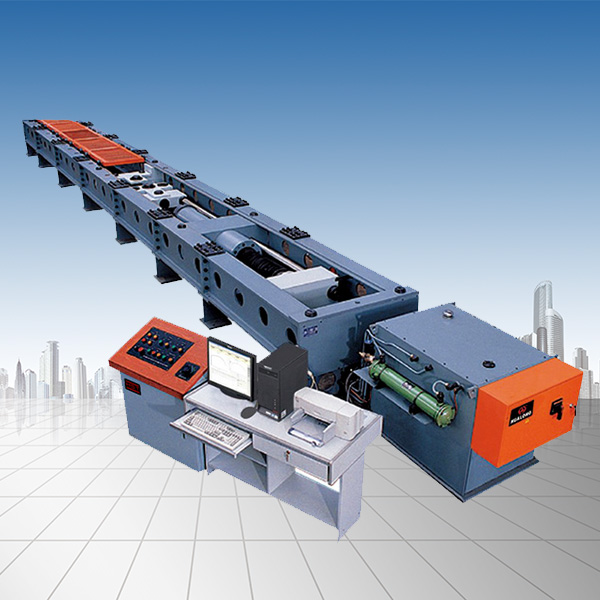

Cement pressure testing machine, also known as cement compressive strength testing machine, is mainly used for cement glue sand compressive strength testing that meets the requirements of GB/T17671-1999 and ISO0679-1998(E). It is the main instrument and equipment of cement laboratory. How much do you know about cement pressure testing machines? Let me introduce to you the requirements for the use of cement pressure testing machines and maintenance.

1. Requirements for the use of cement pressure tester

1. During use, operators should pay attention to the operating noise of lubrication pumps, motors, and frequency converters and the suction and closing sounds of the forward and reverse relays. The equipment failure can be clearly judged from the operating noise. Among them, the motor noise is relatively special, because the inverter outputs three-phase harmonic components.

2. The operator can analyze the direction of zero point drift through a large amount of data accumulation. That is, the data reflects positive or negative deviations. Through the analysis and processing of positive and negative deviations, the experimental data is closer to reality, thereby guiding production more effectively.

3. During long-term use, operators should carefully observe and experience that due to different operating methods (referring to the position and direction of the test block in the fixture), subtle changes in the test data and curves are caused to judge the authenticity of the data and improve the quality of the operators.

4. During operation, the operator should carefully observe the subtle changes in the force measurement curve in the computer display screen of the cement pressure tester, which can reflect the sensor zero point drift, nonlinearity, system tracking performance, and curve changes caused by loose and wear of the mechanical system.

2. Maintenance of cement pressure testing machine

1. The cement pressure tester is installed in a clean, dry, uniform temperature, no vibration around, and no corrosive gas.

2. The cement pressure tester should be kept clean, and parts without protective layer of the tester should be frequently rubbed to prevent rust.

3. The cement pressure tester should be replaced once every six months to one year after use. When changing the oil, the oil tank and oil filter should be thoroughly cleaned. The method of cleaning the oil tank can be used to fill kerosene into the oil tank to clean, then release it, repeat this several times until it is cleaned, and wipe the bottom of the box with a towel, and then add clean hydraulic oil. If you find that the hydraulic oil is severely turbid and cannot be used again, you should replace it immediately, otherwise it will accelerate the wear of each hydraulic component, and even affect the accuracy of the influence value.

After understanding the use requirements and maintenance of the cement pressure test machine, the operator must use it in accordance with the procedures and specifications of the instructions when using the test machine. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any questions during use, you can call our service hotline through the web page, and our technicians will answer them one by one. Welcome to call and support!

Recommended productsPRODUCTS