News

Maintenance and measurement precautions for pressure tester main unit

Release time:2019-09-27 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

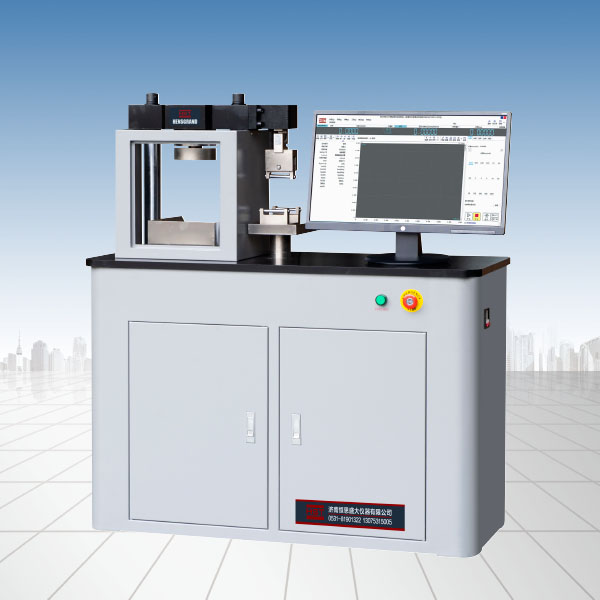

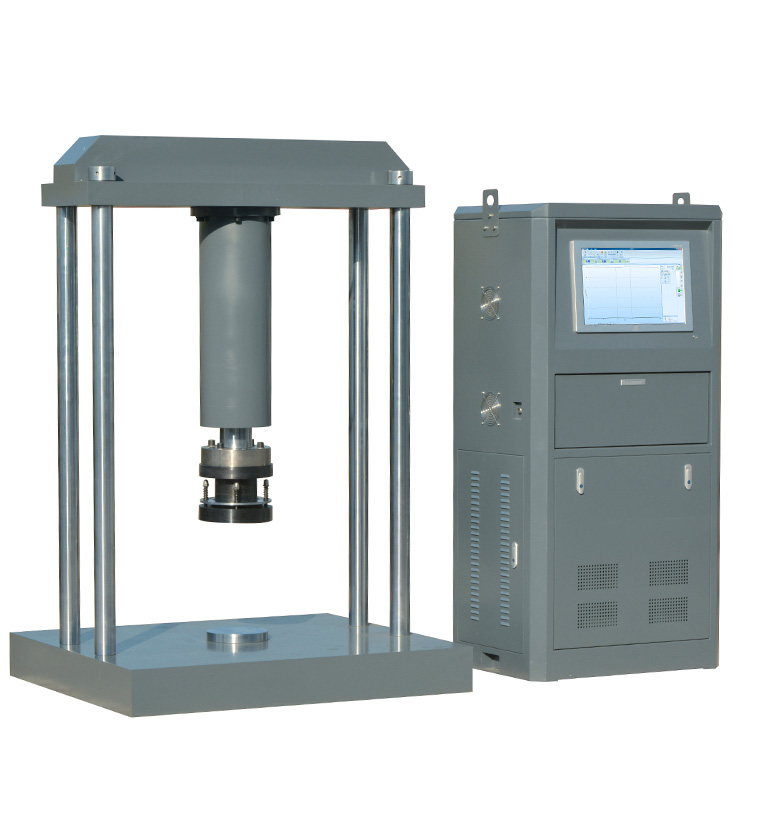

Pressure testing machine, also known as electronic pressure testing machine, is mainly suitable for various physical and mechanical performance testing of rubber, plastic sheets, pipes, special profiles, plastic films, wires and cables, waterproof rolls, metal wires, cartons and other materials. The following is mainly to introduce the maintenance and measurement precautions of pressure testing machine host.

1. Maintenance of the pressure test machine

1. The fixtures equipped with the pressure tester should be coated with anti-rust oil for storage;

2. Since the jaws of the hydraulic universal testing machine are often used, they are prone to wear and tear. When there is too much oxide scale, it is easy to cause damage to the small piston and oil leakage. Therefore, the jaws should be cleaned frequently and kept clean (it is best to clean after each test);

3. The sliding surfaces in which the steel plate inset and the lining plate and the dovetail groove surface on the lining plate should be kept clean, and a thin layer of MoS2 (molybdenum disulfide) grease should be applied regularly;

4. Check the screws in the jaw area regularly. If they are found to be loose, tighten them in time;

5. Check the transmission status of the sprocket regularly. If you find loose, please re-tension the tensioner;.

2. Precautions for measuring pressure test machine

1. Fixture selection

The choice of fixtures is very important. Only by choosing the right fixtures can you do better work. What is a fixture? Fixtures are mainly used on equipment to help equipment measure more accurately. If there is a problem with the clip, the device will definitely be affected in the measurement and cannot measure the accurate data.

2. Check parts problems

When using a pressure tester, you must check the equipment parts. Only by ensuring that the equipment parts are solid and there are no problems, then accurate measurement can be made. However, if there are parts problems during the equipment measurement process, the measurement will be fruitless. Many operators ignore the problem of inspecting parts during the measurement process, which often leads to inaccurate measurement results.

3. Pay attention to cleaning

When using a pressure test machine, you must pay attention to cleaning. Only by cleaning regularly can you ensure the accuracy of the equipment measurement data and extend the service life of the equipment. If the operator does not pay attention to cleaning issues, the equipment measurement will definitely cause large errors.

4. Understand the measurement standards

Understanding measurement standards is critical, but it has been ignored by many people. For example, pressure testing machines can only measure metal and non-metallic materials, while people measure rubber materials, resulting in data results being unable to be obtained, and it will also cause damage to the equipment.

Mechanical equipment is essentially the same. The coordinated operation of different components can only make the entire experimental process smoother and the experimental data more accurate. In summary, it is a related introduction to the maintenance and measurement precautions of pressure tester host machine. I hope it can help you.

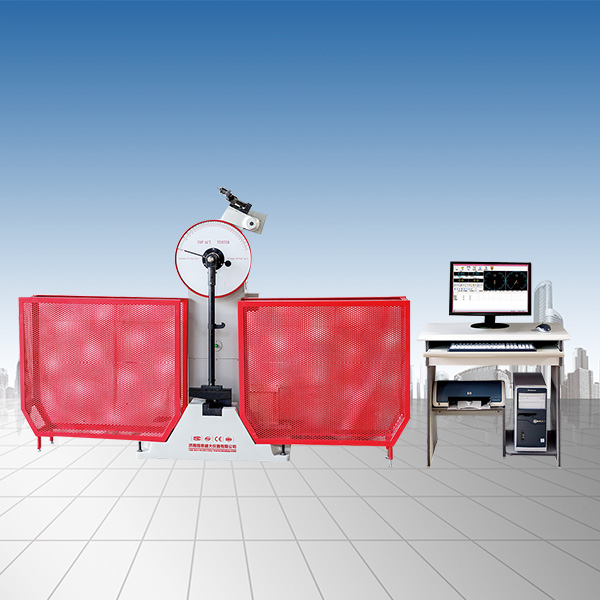

Recommended productsPRODUCTS