News

Precautions for purchasing tensile testing machines and their application in aviation materials

Release time:2019-10-08 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

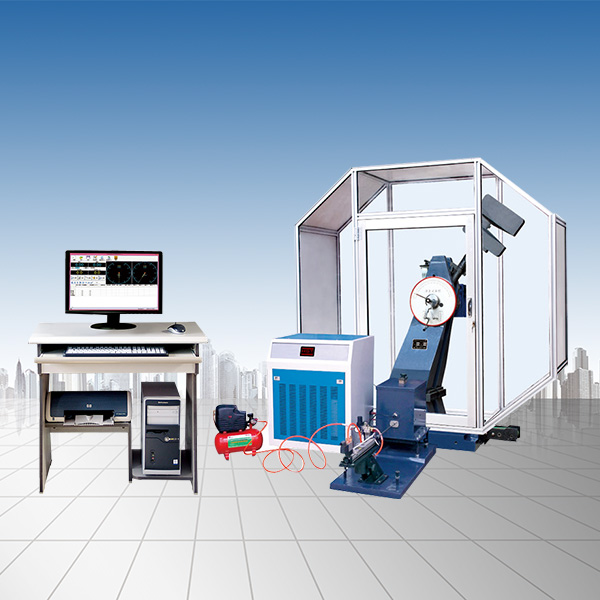

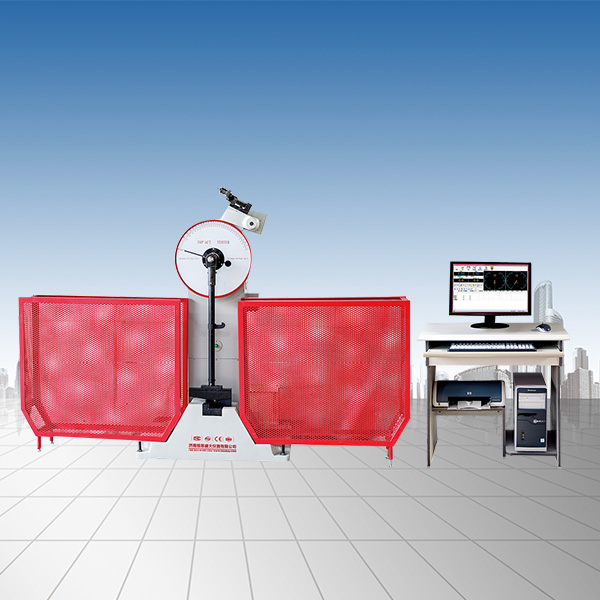

The tensile tester uses imported photoelectric encoder for displacement measurement. The controller adopts an embedded single-chip microcomputer structure and has built-in powerful measurement and control software, integrating measurement, control, calculation and storage functions. It has the functions of automatically calculating stress, elongation (with an extensometer), tensile strength, and elastic modulus. How much do you know about tensile testing machines? Let me introduce to you the precautions for purchasing tensile testing machines and the application of aviation materials.

1. Things to note when purchasing tensile testing machine

1. Capacity, test stroke, configuration

Different tension ranges and different force sensors are configured, resulting in different structures, which will directly affect the cost of the instrument. For general flexible packaging manufacturers, the tension range of 300 Newtons is enough.

According to the performance and requirements required for the soft packaging film, the stroke is 600-800mm;

Three intelligent options and configurations: host, computer, and printer, and microcomputer functions can also directly print electronic receipts. In addition, it can also be equipped with a normal computer. If you use a computer, the manufacturer needs to configure professional testing software. With a computer, you can perform complex data analysis, such as generating test reports, editing data, partial amplification, adjusting the report format, and conducting statistical analysis of group styles.

2. Test items

Flexible packaging requires that one tension machine is used for multiple purposes, that is, on the basis of equipped with different fixtures, it can be used for stretching, compression, bending, tearing, shear, 180-degree peeling, 90-degree peeling test, three-point flexion resistance, four-point flexion resistance, etc.

3. Test speed

Some commercially available tensile machines are between 30 and 400 mm/min, while others are between 0.01 and 500 mm/min. The former generally uses a normal speed control system, which is relatively low in cost and roughness affects accuracy. The latter uses servo systems, which are expensive and have high accuracy. For flexible packaging companies, it is ideal to use servo systems with a speed regulation range of 0.01~500mm/min. This not only meets the accuracy requirements, but also costs within a reasonable range.

4. Measurement accuracy

Accuracy issues, including force measurement accuracy, speed accuracy, deformation accuracy, and displacement accuracy.

5. Transmission

There are screw transmissions and rack transmissions. The former is expensive, used for high accuracy and has high repeatability for tests; the latter is cheap, used for low accuracy and has low repeatability for tests. Flexible tension machines are frequently used and require high accuracy, so lead screw transmission should be selected. The screw has a decisive effect on the measurement of tension accuracy. Generally, there are ball screws, trapezoidal screws, and general screws. Among them, ball screws have the highest accuracy, but their performance can only be achieved by operating the computer servo system. The whole set is also relatively expensive. Furthermore, ball screws are divided into domestic and imported, and the prices and quality of both are very different.

2. Application of tensile testing machine in aviation materials

Why does the windshield break? This involves the mechanical properties of the material. The mechanical properties of a material refer to the behavior of the material under the action of an external load or under the combined action of the load and ambient temperature. The mechanical state of a material withstands load is generally represented by various mechanical parameters (such as stress, strain, impact absorption energy, stress strength factor, etc.), while the critical value or specified value that characterizes the mechanical behavior parameters of the material is called the material's mechanical properties index (such as yield strength, plastic strain, fracture toughness, creep strength, fatigue limit, fatigue crack propagation threshold value, etc.). These performance indicators are not only the basic basis for evaluating and selecting materials and determining processing technology, but also are indispensable and important basic data for engineering applications, structural strength design, life prediction and structural integrity evaluation, and are a bridge connecting material and process research, structural design and engineering applications. The carrying capacity of modern aircraft refers to the guarantee ability of the safety, reliability, comfort, economy and maintenance of the aircraft operation under specific service time and service conditions (complex alternating loads, high temperatures, high speeds and corrosive environments, etc.). The bearing capacity depends on the structural design of the engineering equipment and the mechanical characteristics of the materials. Compared with other engineering equipment, aviation equipment has stricter requirements for material performance and more advanced performance indicators. Moreover, for different types of aircraft, the focus of design on material performance requirements is also different. Therefore, higher requirements are put forward for the detection, characterization and evaluation of mechanical properties of aeronautical materials. The authenticity, effectiveness and reliability of the inspection data are the basic requirements put forward by the aviation industry for the inspection of materials mechanical properties. However, there are many factors that affect the authenticity, effectiveness and reliability of material mechanical properties testing data, mainly involving testing equipment, testing methods, testing environment, measurement traceability, sample status and testers. Among them, the testers are not only the subject of testing, but also the first factor to ensure the authenticity, effectiveness and reliability of the detection data, and are also the practitioners who control the other five factors. The degree of mastery of testing equipment, the degree of understanding of testing standards and methods, etc., will have a significant impact on the quality of testing work.

Mechanical equipment is essentially the same. The coordinated operation of different components can only make the entire experimental process smoother and the experimental data more accurate. In summary, the above are the precautions for purchasing tensile testing machines and the relevant introduction to the application of aviation materials. I hope it can help you.

Recommended productsPRODUCTS