News

Key points of use and maintenance of metal tensile testing machine

Release time:2019-10-16 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

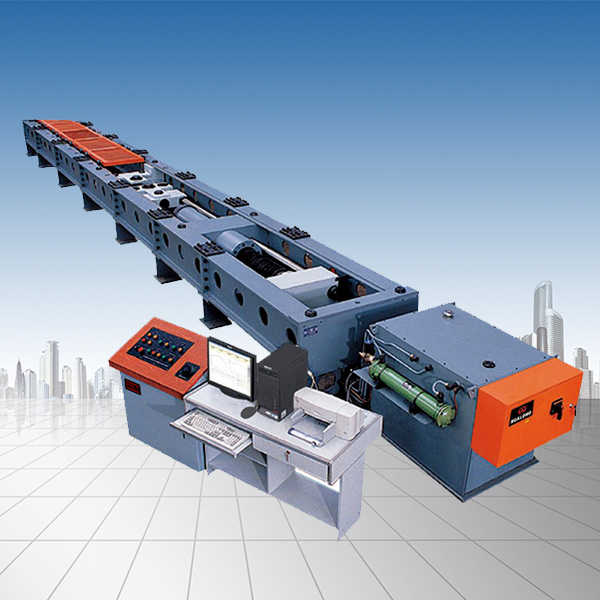

The metal tensile testing machine is used to detect mechanical properties such as peeling, tearing, bonding, opening, stretching, deformation, heat sealing, puncture, pulling, pulling, pulling force, etc. of wires, cables, food, aluminum-plastic pipes, films, paper, mechanical manufacturing, porcelain, pharmaceutical packaging, geotextiles, wood, metal materials, etc. Next, our technicians will introduce the key points and maintenance of the metal tensile testing machine in detail.

1. Key points of use of metal tensile testing machine

1. During the use of the metal tensile tester, the gears must be smooth and prevent dry transmission during the movement. As time goes by, it will increase wear. Too much smooth oil will also stick to a lot of dust, so it is essential to ensure the cleanliness and hygiene of the operating room of the metal tensile tester.

2. What are the smoothness and oil discharge of the metal tensile tester? The top of the base of the main body is equipped with an oil injection hole, which is smooth. Through this hole, the nut is smooth, and the threads of the screw are used for lifting and landing of the lower jaw seat.

3. After application, the transmission should be usually smooth to prevent wear and transmission. After the main device is completed, the oil probe needle is passed through the seat hole of the oil probe needle on the top of the base, and the engine oil is injected into the oil pool with a funnel. The oil depth is 30 mm, and it is measured with the oil probe needle.

2. Maintenance of metal tensile testing machine

1. Before the test, the system must be preheated for more than 20 minutes to minimize the temperature impact.

2. The oil used for the buffer should be kept clean. If the oil level is less than two-thirds of the barrel depth, it should be replaced immediately.

3. Before starting the machine, check whether lubricating oil should be added to the frictional moving parts.

4. Before adding the test piece, the metal tensile tester must jam the brake handle, add the test piece and release it.

5. Refueling is not allowed on the main bearing of the dynamometer. The surface of the friction wheel in the gearbox must not be refueled or oil stains splashed. The friction surface should be absolutely clean and the inclined block on the swing arm must not be violently impacted.

6. After the test is completed, after the power is cut off, the test machine will be cleaned and protected in time.

7. The tensioner is maintained twice a month on average.

Instrument operators should carefully read and understand the maintenance of the instrument, maintain the instrument well, so that the instruments are always clean, the parts and accessories are complete and safe, and ensure the normal operation of the instruments. The above is an introduction to the key points and maintenance of the metal tensile testing machine. I hope it can help you.

Recommended productsPRODUCTS