News

Daily maintenance and use techniques of corrugated tube ring stiffness tester

Release time:2019-10-17 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

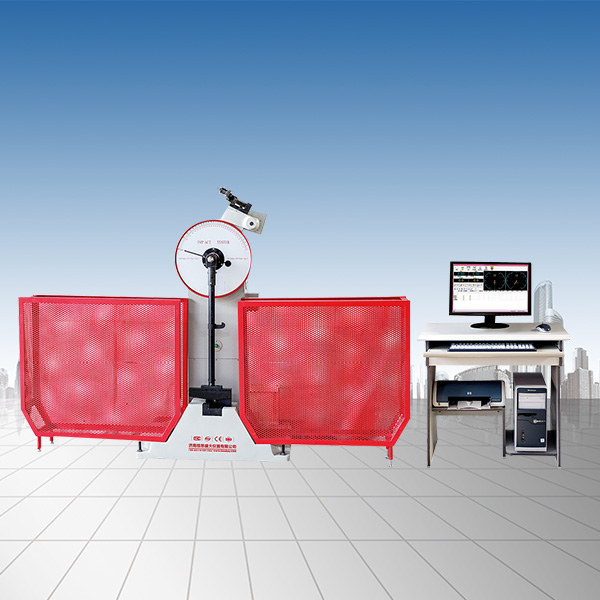

The corrugated pipe ring stiffness tester is widely used in the determination of the rigidity of thermoplastic plastic pipes and fiberglass pipes with an annular cross-section, meeting the requirements of pe double-arm corrugated pipes, winding pipes and various pipe standards, and can complete the tests of pipe ring stiffness, ring flexibility, flatness, weld tensile. The long-term use of the test machine is inseparable from our daily maintenance. The editor will tell you about the daily maintenance and use techniques of the corrugated tube ring stiffness test machine.

1. Daily maintenance of corrugated pipe ring stiffness test machine

1. Before the test, the system must be preheated for more than 20 minutes to minimize the impact of temperature drift.

2. The oil used for the buffer should be kept clean. If the oil level is less than two-thirds of the barrel depth, it should be replaced immediately.

3. Before starting the corrugated tube ring stiffness tester, check whether lubricating oil should be added to the frictional moving parts.

4. Before adding the test piece, the brake handle must be stuck, and then release it after adding the test piece.

5. Refueling is not allowed on the main bearing of the dynamometer. The surface of the friction wheel in the gearbox must not be refueled or oil stains splashed. The friction surface should be absolutely clean and the inclined block on the swing arm must not be violently impacted.

6. After the test of the bellows ring stiffness tester is completed, after the power is cut off, the tester will be cleaned and protected in time.

7. The tensioner is maintained twice a month on average.

2. Usage skills of corrugated tube ring stiffness test machine

1. When purchasing, users use it to perform simple tensile tests, compression tests, etc., and only need to bring conventional accessories. For accessories that cannot be used for stretching, bending, peeling, tearing, etc., it is impossible to use. Therefore, users must not think that the more you buy, the better. After all, if you exceed the conventional configuration, you will have to charge additional money.

2. Because of the characteristics of the pipe, the test space of the bellows ring stiffness tester sometimes needs to reach 3 meters, but some users often choose the 3-meter model when the test space is about 2 meters, which will cause some waste. Moreover, the longer the length of sheet metal and lead screws, the more the price.

3. The models of this device can be roughly divided into digital and microcomputer control. No matter which model of the two devices, they fully meet the mechanical standards of pipe inspection, but some functions and the way of displaying data are different. For example, most small and medium-sized enterprises, when the data and function requirements are not not many and the digital display can meet, there is no need to spend more money to buy microcomputer control.

To sum up, it is a detailed introduction to the daily maintenance and use techniques of the corrugated tube ring stiffness test machine. The maintenance of the test machine is very simple. As long as you check and clean it up after each use of the test machine, it will not only save working time, but also effectively extend the life of the test machine.

Recommended productsPRODUCTS