News

Some common faults and precautions for spring testing machines

Release time:2020-06-02 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

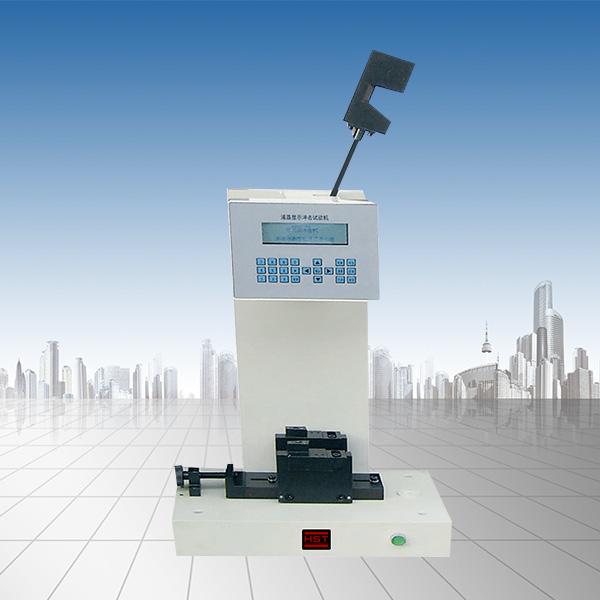

Spring testing machine is an instrument that specializes in testing and analyzing the spring's tensile force, pressure, displacement, stiffness and other strengths. The product has the advantages of stable performance, flexible use, high reliability and easy maintenance. The skin production is widely used in many industries. The spring tester will cause certain faults during use, which will have a certain impact on the user's use. Here are some common faults and precautions for your reference:

Common faults of spring test machines:

1. The spring tester switch is not displayed. Check whether the power supply of the 220V power supply and the microcomputer system are normal. If the fuse is disconnected, it should be replaced.

2. The conflict of the display errors of the two dials (that is, the display error marks are the same) occurs because of the comparison and balance sweeping method of the lever 30: mobilize the two-end tool holders 33, that is, when the maximum error is ≥±1%, move the two-end tool holders to the right, and vice versa, and adjust and tighten.

3. The reason why the value error of the whole pair exceeds the positive value or the full pair exceeds the negative value is the change of the number of invalid turns of the tension spring: the positive value rotates the hooks at both ends of the tension spring inward to reduce the number of invalid turns. It's negative, the position is the same, and the number of invalid circles increases.

4. The spring tester is the same as on the upper dial. The error of the value is negative in front and positive behind or the same occurs because the orchestration on the needle does not have an appropriate method to clean the orchestration on the needle: if the front and positive behind, one end of the toe of the needle is heavy, and the other hand end is light. Identify the lightest end of the solder to relieve the light.

5. The reason for the large negative error at the end of the spring tension tester is that the limit screw 29 is too high, and the deformed distance of the obstacle lever is swept away: adjust the limit screw appropriately lower

Notes on using spring tester:

1. During the test of the spring test machine, the electrical appliance suddenly fails and the start or stop button does not work. The power supply should be cut off immediately to stop the machine.

2. The function of moving crossbeam is to adjust the test space. During the experiment, it is strictly forbidden to start the movement measurement when applying force and unloading force, otherwise it may cause the lifting and lowering driving mechanism to fail.

3. All parts of the spring tester should be wiped clean frequently. Wipe the surface without spray paint and apply a quantity of cotton yarn sand to prevent rust. Pay more attention to wiping during the rainy season. When the instrument is not suitable, use a dust cover to prevent dust from invading.

The above are some common faults and precautions for spring testing machines. You can collect the above articles in case of emergencies. In short, you should pay attention to the problems found during use of the testing machine and promptly eliminate them to avoid errors in your test results. It is to regularly check and correct the test machine to ensure the normal use of the test machine. If you need to know more, please call us for consultation.

Recommended productsPRODUCTS