News

Operation steps and functional characteristics of the drop hammer impact test machine

Release time:2020-05-07 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

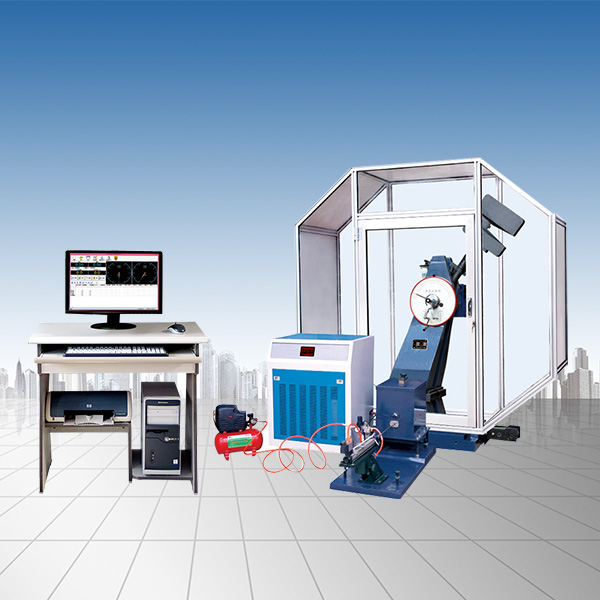

The drop hammer impact tester is suitable for the determination of external impact resistance of various pipes (PVC-U water supply pipes, sewage pipes, low-pressure water supply pipes, low-pressure water supply pipes, core foam pipes, double-wall corrugated pipes, PE water supply pipes), and plates, and is also suitable for hard plastic sheets. Do you know the operating steps and functional characteristics of the drop hammer impact test machine? The following editor will give you a detailed introduction.

1. Operation steps of the drop hammer impact test machine

1. According to the test requirements, determine the mass and impact height of the hammer and make samples for later use.

2. Determine the mass of the hammer.

3. The hammer impact tester puts the hammer rod on the sliding sleeve under the hammer seat, and puts the selected weight on the hammer rod and tightens the nut.

4. Turn on the power and enter the working state.

5. Press the "Slow Up" key to lift the hammer away from the bottom and press the "Stop" key to facilitate the installation of the sample.

6. Open the laboratory door and place the sample on the V-shaped iron.

7. Observe the status of the red indicator light of the photoelectric switch on the left: Off means that the sample is too high and the light cannot pass, and on means that the sample is low and the light can pass. Adjust the lifting handwheel so that the upper busbar of the sample and the center of the photoelectric tube are on the same level. .Determine the height zero point: Use the "slow down" and "slow up" keys to make the hammer head just in contact with the sample, and press the zero point of the height display table "Zero".

8. Close the protective net and door, press the "Quick Up" key, and the ruler indicates the lifting height. After raising it to the predetermined height, press the "Stop" key.

9. Impact: First press the "Pre-fall hammer" key to make the indicator light on this key, then press the "fall hammer" key to drop the hammer and impact the sample. Note: Press the "Pre-fall hammer" key: the key stop indicator light does not light, which means the sample is too high and the sample height needs to be readjusted. "Pre-fall hammer" key: Press this key to enter the pre-fall hammer state (after the sample is installed), press the "Pre-fall hammer" key, the hammer body will fall immediately, and press other keys to remove the hammer state.

10. After the hammer body impacts the sample and the sample is not broken, causing the hammer body to rebound, the photoelectric signal controls the hammer holding mechanism to quickly clamp (connect) the rebound hammer body to achieve the purpose of preventing secondary impact.

11. Press the "Quick Down" key, insert the pin on the hammer seat into the solenoid valve seat, and press down the micro switch to stop the downward.

12. Follow the second step, take out the sample, then put in a new sample, repeat steps 3-9, and you can also perform some adjustment and inspection work in the middle and then. Shut down: turn off the power switch of the electrical control box and the main power supply.

2. Functional characteristics of the falling hammer impact test machine

1. Movement control: The upper and lower heights can be automatically controlled by computer.

2. Positioning device: The drop height can be automatically controlled by the computer.

3. Lifting device: Computer-controlled lifting and lowering of electromagnets and dropping hammers.

4. Capture device: The electromagnet automatically captures to prevent the sample from being impacted by secondary impact.

5. Buffering device of the drop hammer impact tester: The equipment is equipped with a buffering device to prevent damage to the drop hammer impact surface.

6. Data editing: After the test is completed, the impact damage quality and corresponding data can be automatically calculated and displayed by the computer.

7. Curve drawing: After the test results of all samples are completed, marks can be automatically drawn on the table, which is intuitive and clear.

8. Report editing: Test data and marker forms can be automatically edited into reports and printed.

After understanding the operating steps and functional characteristics of the drop hammer impact test machine, the operator must use it in accordance with the procedures and specifications of the instructions when using the press. Otherwise, it is easy to cause dangerous situations such as machine failure and personnel injury. If you have any unclear areas, please call us for consultation. So that we can choose the product that suits you according to your actual situation

Recommended productsPRODUCTS