News

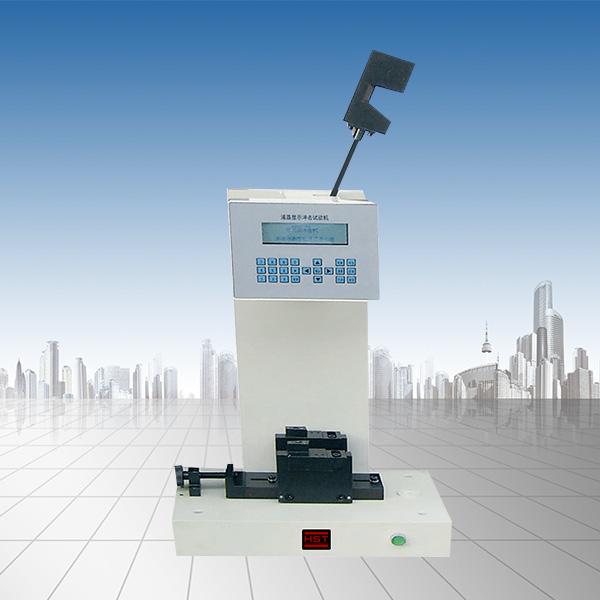

Mining three-ring chain tensile testing machine

Release time:2022-06-24 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Structure and performance of mining chain tension testing machine:

The mining chain tension testing machine consists of four parts: the main part, the oil source part (hydraulic power source), the measurement and control system, and the test attachment.

Main structure of chain tension testing machine:

The main unit of the chain tension test machine is a six-column frame-type double-space stable structure with four columns and double lead screws. There is a tensile space between the upper beam and the lower beam, and there is a compressed space between the upper beam and the workbench.

The main body of the chain tension tester is composed of main components such as base, oil cylinder, oil cylinder seat, lower jaw seat, upper jaw seat, column, lead screw, small cross beam, etc. The oil cylinder is installed on the cylinder seat, and the upper end of the piston is connected to the small cross beam through a load sensor. The base is tightly connected to the upper cylinder seat through four columns. The moving beam can be moved up and down between the base and the cylinder seat along the lead screw to adjust the stretching and compression space. The oil cylinder is a dual servo cylinder. The unique processing technology ensures the precise clearance between the cylinder and the piston, and the piston is flexible to lift and lower.

During the test, the sample is placed in the tensile jaw between the upper and lower jaw seats. The hydraulic oil is sent smoothly from the lower part of the oil cylinder to the pressurization chamber, driving the piston to rise, driving the load sensor, small beam, lead screw, and upper chuck to move upwards together, and the sample is stretched. Depending on the length of the sample, it can be adjusted to a suitable position by moving the upper chuck up and down. The compression test is performed in a compression space composed of the cylinder base and the moving chuck. The same action of the oil cylinder can complete the compression test in the space below the cylinder seat and above the moving chuck. After replacing the bend and shearing attachment in this space, the bend and shearing tests of the sample can also be performed.

After the test, the piston automatically returns to position under the action of gravity of small cross beams, moving chucks, lead screws, pistons, etc.

- Previous article:Selection elements of universal testing machine

- Next article:Performance indicators of fasteners and high-strength bolt tensile tester

Recommended productsPRODUCTS