News

Testing method of metal rods by testing machine

Release time:2022-08-12 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1. Stretch

Tensile testing provides a relatively simple and low-cost technology for developing or evaluating the mechanical properties of metal materials, which provides information on the reaction of metals and alloy materials to mechanical loads. In some cases, manufacturers can test samples that are very close to the final product. In other cases, the raw material must be cut or folded. Both types of tests are practical in material comparison, quality control inspection and alloy development. Many important factors need to be considered in bar sample testing, and the metal tensile testing machine is specially designed for this. To meet the fixture requirements for material testing, our company provides a series of various flat-mouth, v-shaped or special fixtures. Most wedge clamps have a front opening design, which provides sample tooling for shoulder and threaded ends. The split sleeve design of shoulder-end sample tooling accelerates the progress of production site testing.

2. BendingBending tests provide important information about the plasticity and toughness of the material. The suitability of the material needs to be tested. Due to the diversity of materials, samples and applications and the continuous development of materials science, special test fixtures are needed. Determined based on the sample diameter and bending diameter. The bending fixture provides adjustable support span and replaceable centers, so that a single fixture can be used for bar tests of multiple sizes.

3. Cut

Many applications and product designs use bars affected by shear stress. These applications range from simple pins and U-hook adapters to safety pins that serve as mechanical safety devices to protect expensive equipment. Therefore, it is necessary to understand the properties of bars under actual shear conditions.

4. Turn

The torsion test can test material characteristics such as shear modulus, maximum shear strength, shear fracture modulus and plasticity. To determine the above-mentioned material properties, it is necessary to accurately measure the torque distance and torsion angle on a fixed scale. Although it may seem simple, the torsion test increases the difficulty of testing because the bars are often difficult to clamp, and the torsion angle is not easy to measure. The sample often needs to be processed into a small intermediate area and is diagonal or hexagonal at the clamping end.

To obtain accurate test results, it is crucial to keep the test samples in the fixture centered. During the test, the circular sample is difficult to clamp without sliding. Chuck-type torsion fixture, circular, hexagonal or diagonal specimens.

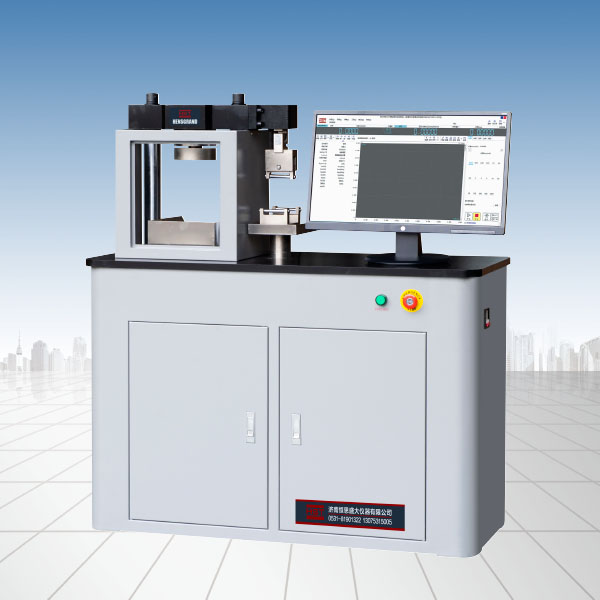

Recommended productsPRODUCTS