Current location:front page >> News

News

Electronic universal material testing machine is used for wire tension testing, what is the jaw breakage

Release time:2022-10-21 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

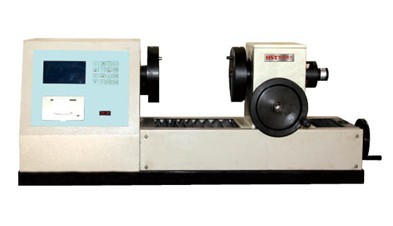

The electronic universal material testing machine is the product of the combination of modern electronic technology and mechanical transmission technology. It is a large precision testing instrument composed of full play to the strengths of mechanical and electrical strengths. It can conduct a variety of performance tests such as tensile, compression, bending, peeling, and shear on various materials.

Electronic universal material testing machines can be used for tensile testing of many materials, including physical properties testing of non-metallic materials such as rubber, plastic, papermaking, textile, and wires, and are also used for tensile testing of steel wires. However, there is a strange phenomenon. In tensile testing of steel wires, jaws always break. What's going on? Sansi believes that this problem is generally a small gap formed by the jaw teeth engaging the steel wire, that is, a breaking source is formed, and its impact size is related to the following factors.

1. During tensile tests of various steel wire materials, the anti-breaking ply is in place, and the ply ribs are used to match the materials of each steel wire.

2. Plywood and shearing plywood materials have a direct impact. Plywood made of ordinary steel and iron parts must not be able to clamp the steel wire. Another important thing is the material of the tooth blocks in the splint.

3. Effect of notch shape

Due to the different jaws and incisions of tensile testing machines, this effect is greater when the incision is at an acute angle; when the gap is an obtuse angle, the effect is very small.

4. The influence of wire diameter

The contact area between the small diameter wire and the wire clamp is small and it is not easy to snap in. The wire clamp is prone to notches, which greatly increases the sensitivity of the small diameter wire to the notches. Therefore, it can be seen that the diameter of the steel wire uses different shapes of clamps.

The required breakage value of large diameter steel wire (greater than 2mm) is large, and the contact area between the sample and the ply plate is large, and its biting speed is fast, making it difficult to cause the ply plate to break due to slippage or surface notches, so large diameter steel wire is not sensitive to the notches.

5. The influence of wire strength

High-strength steel wire has greater sensitivity to notches than low-strength steel wire. Generally speaking, high-strength steel wire has poor toughness and high brittleness, and small gaps will cause it to break; low-strength steel wire with good toughness is not easy to break.

Recommended productsPRODUCTS