News

Common obstacles and methods for e-tension testing machines

Release time:2025-03-25 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

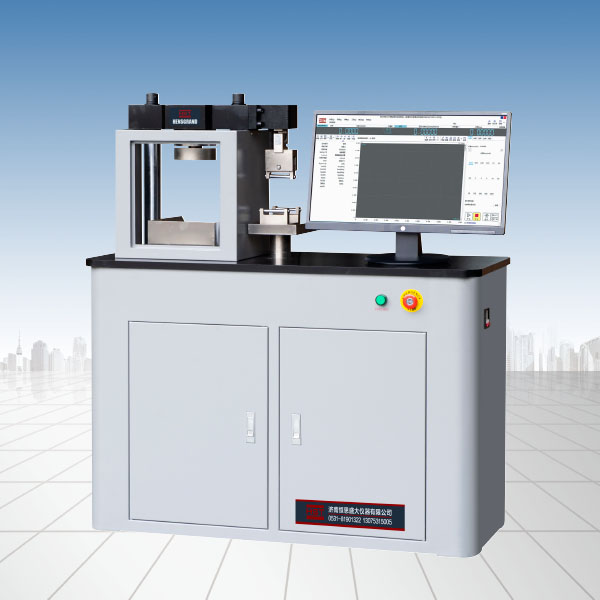

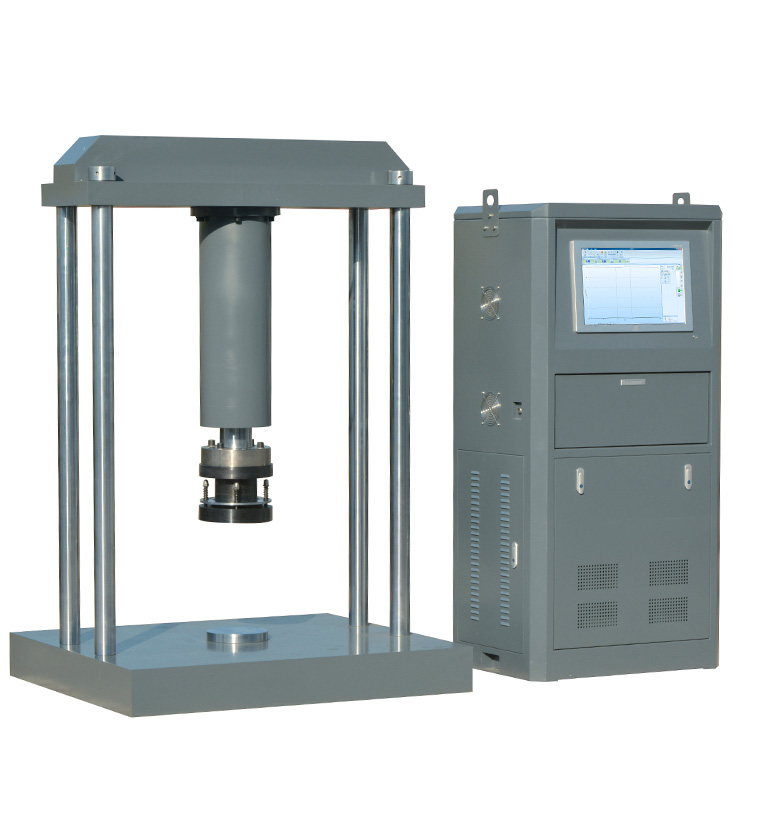

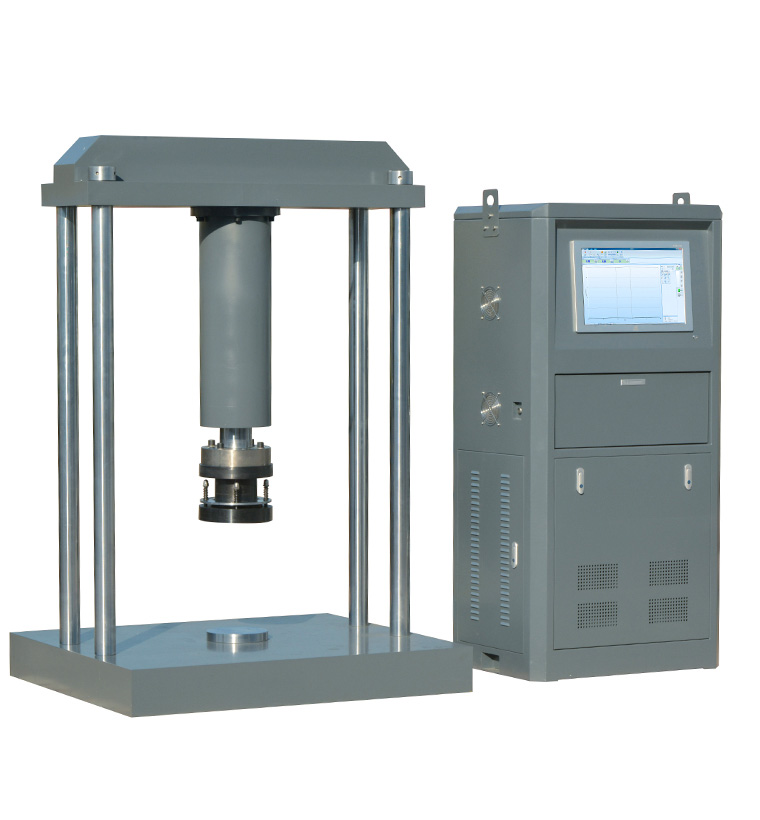

The electronic tension testing machine has the characteristics of beautiful appearance, convenient operation, stable and reliable performance. It is mainly used for tensile, peeling and tearing tests of metal and non-metallic materials such as metal wires, metal foils, plastics, rubber, food packaging, textile fibers, wires and cables. However, there are problems of one kind or another during the testing process. So, what are the common faults and methods for troubleshooting electronic tensile testing machines? Let’s take a look with the editor below.

Fault 1: Abnormal vibration and noise

Troubleshooting method:

1. Please check whether the four legs of this machine are in contact with the base evenly. If not, adjust the four legs to make them evenly contact.

2. Check whether the system power supply voltage is normal and stable. If not, please replace the stable and normal power supply.

3. Check whether the screws on each part of the machine are loose. If loose, tighten the screws.

Troubleshooting method:

1. Please first confirm whether the "test" is clamped correctly. If not, please clamp correctly.

2. Please check whether the settings of "force sensor" and "decoder" are correct. If not, please refer to the operating instructions and the settings are completed.

3. Please check whether the "force zero" and "deform zero" keys have been pressed before testing. If not, please restart the test at Hainan Vitiligo Hospital and press the "First Zero" and "Deformation Zero" keys before the test.

The above is about "What are the common faults and troubleshooting methods for electronic tensile testing machines?" I hope it will be helpful to you. If you have any other questions, please feel free to consult our company.

Recommended productsPRODUCTS