Company News

Material torsion test machine masters the selection of model through 3 points

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Material torsion test machine masters the selection of model through 3 points

Many customers often encounter many misunderstandings when purchasing material twisting test machines. Technical engineers from Jinan Hengsi Shanda Instrument Co., Ltd. have sorted out a series of problems in twisting test machines, hoping to help the majority of users.

1. Range selection

Select the required test machine load (i.e. range) according to the load of the test material. It is best to recommend that the material test load is about 70%-90% of the test machine range. This not only ensures the resolution of the test but also extends the service life of the test machine.

2. Selection of accuracy level

At present, the accuracy of domestic test machines is generally used in level 1 and level 0.5. It is sufficient to choose a level 1 test machine for general material tests. There is no need to spend more money to improve the accuracy. For scientific research and material analysis, test machines with level 0.5 accuracy are required. In fact, the technical differences for level 0.5 and level 1 test machines are not obvious. The calibration methods and methods are basically the same. This is the difference in correction points. With the development of sensor technology, the linearity of sensor elements has reached a very high level. As long as the measurement circuit has no defects and good anti-interference performance, all test machines will reach level 0.5 accuracy. There is no problem with electrical measurement, which has far exceeded the limit of level 0.5. The relative error defined by national standards is defined by the national standard.

3. Resolution and dynamic performance (bandwidth) selection

Resolution is an important parameter of the test machine. Appropriate resolution will be conducive to the measured resolution and measure smaller indexing. Effective resolution and dynamic performance are a contradiction. Blindly improving the effective resolution is at the expense of dynamic performance (bandwidth). The direct result of the reduction in bandwidth is that the material yield fluctuations are not obvious or even yielding is a platform phenomenon, so when selecting the model, this pair of parameters must also be considered effectively;

Tags: Universal Testing Machine Hydraulic Universal Testing Machine Electronic Universal Testing Machine Electrohydraulic servo universal testing machine

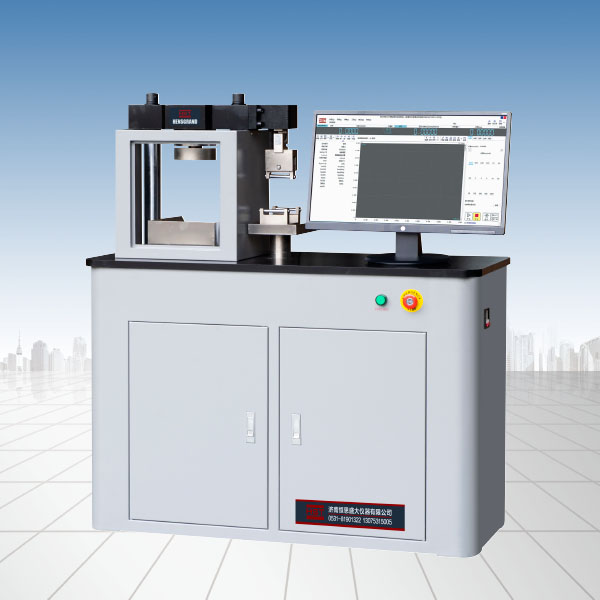

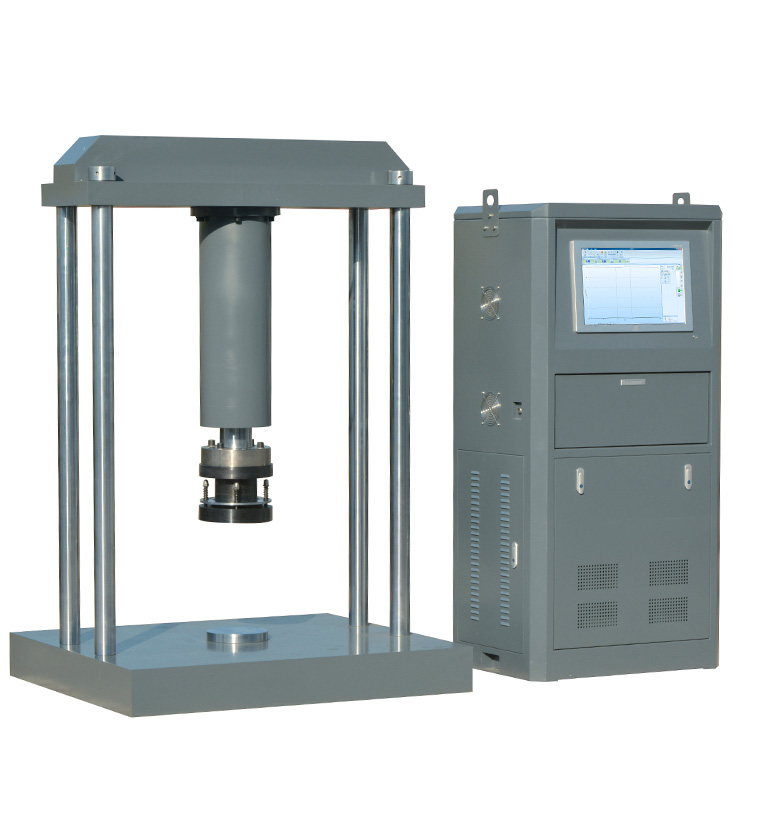

Recommended productsPRODUCTS