Company News

Advantages of rolling wear tester

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Rolling wear testing machines can generally be divided into two types: evaluating lubricants and evaluating material wear resistance. During the test, samples of certain shapes and sizes will be made by the European materials according to the prescribed requirements. Table 10-1 lists several common friction test machines.Advantages of rolling wear testerYes: (1) Easy to use and high tester accuracy. (2) The test standards are relatively unified, the data obtained from the test are good and can be better compared to the parts, while the test costs are low and the cycle is short. (3) It is suitable for studying the friction and wear characteristics and models of the material itself, and can effectively control various influences: (4) It is very effective in evaluating the lubrication performance of process lubrication, such as oil film strength.

Although the rolling wear tester has the above advantages, the friction coefficient is affected by many factors and also changes with the deformation conditions. Therefore, there is no universal universal testing machine and standard testing method to determine the friction coefficient under rolling conditions. At the same time, since the test conditions such as deformation mode, contact conditions, and specimen material do not fully meet the actual working conditions, the friction coefficient test results are only of reference value.

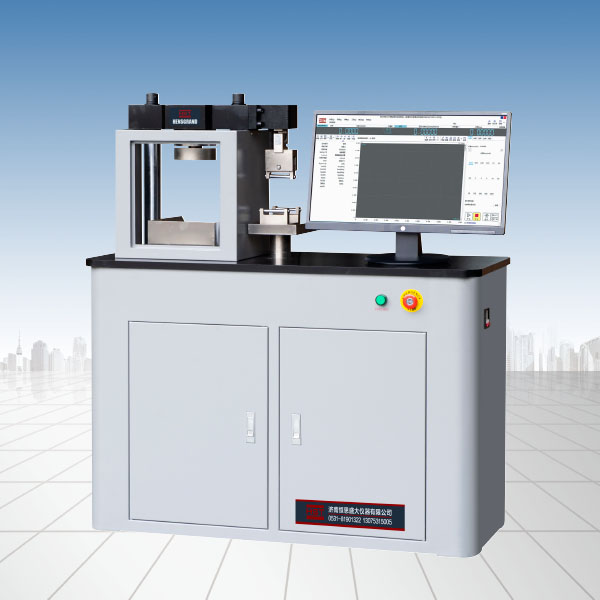

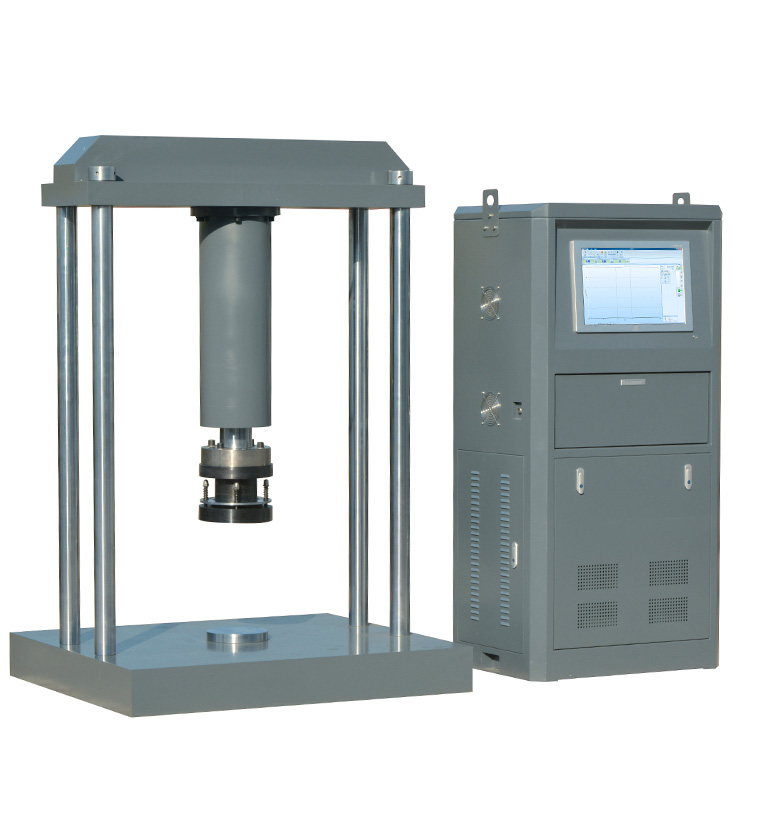

Recommended productsPRODUCTS