Company News

Introduction to the functions of universal testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

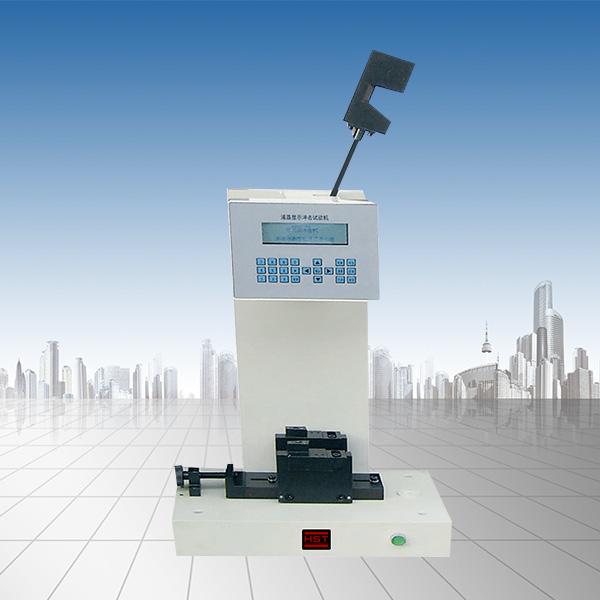

Universal testing machineIt is designed and manufactured according to the national standard GB/T 16826-2008 "Electro-hydraulic servo universal test machine". The host adopts a high stiffness design, and each stressed component is analyzed, designed by finite element, and has been precision machining and tested. The oil source system adopts a load-adaptive throttling speed control system, which is repeatedly pressurized and load-held. The controller adopts a new generation of high-performance, intelligent fully digital independent controllers, and the measurement and control software adopts a combination of advanced measurement and control algorithms to accurately control the entire test process and fully meet the requirements of domestic and international material testing methods. The main functions of the universal testing machine:

Universal testing machine is based on the national standard GB/T 16826-2008 "electro hydroulic servo universal testing machine design and manufacturing". The host adopts highrigidity design, each stress components by the finite elementanalysis, design, precision machining and testing. Oil source system by using the load adaptive throttle speed controlsystem, after repeated compression test and maximum loadand load test. The controller uses a new generation of high performance, intelligent digital independent controller, control software adopts the advanced control algorithm combination,can accurately control the whole process of the experiment,fully meet the test method of the domestic and international material requirements. The main function of universal testing machine:

The universal testing machine is an important instrument and equipment that tests the physical properties, mechanical properties, process properties, structural seismic strength, and internal and external defects of various materials and their products in various environments and simulated states. Tests such as tensile, compression, bending, shearing of metal or non-metallic materials can be achieved according to the corresponding standards. Performance indicators such as tensile strength, yield strength, specified non-proportional extension strength, elastic modulus of the measured material can be obtained, and closed-loop control such as equal rate loading, equal rate deformation, equal rate displacement, and equal rate strain can be achieved. Process qualification performance verification tests of materials or products can be carried out.

Universal testing machine is physical properties, testing of various materials and products in a variety of environment and the simulation state mechanical properties, process performance, seismic intensity structure as well as themes and components of internal and external defects in an important instrument and equipment. In accordance with the corresponding standards, tensile test of metal or non-metal materials compression, bending, shear type, can be obtained from the measured tensile strength, the yield strength of the material, specified non proportional extension strength, elastic modulus and other performance indicators, realizing rate loading, constant rate deformation, displacement, velocity constant the strain rate of closed-loopcontrol, the process can be material or product qualified performance verification test.

The universal testing machine is designed to consider the possibility of extending the assembly of other fixtures to complete more tests. For example: fitted bolt clamps can be used for tensile and load maintenance of bolts, fitted shear strength tests for round rods, and fitted with anti-flexion, shear, splitting, elastic modulus meter, etc. in the compressed space can be used for concrete and cement sample block tests. With special fixtures such as steel balls, anchor chains, fasteners, etc., you can complete various tests of the corresponding products.

Design of universal testing machine considering the assemblyfixture to complete the expansion of other more trials may.Such as: tensile loading bolt to bolt clamp and holding, with shear fixture can be round bar shear strength test, in the compression space is added to the flexural, shear, splitting,elastic modulus tester to do concrete and cement sample test, with special fixture, the ball, to be completed by the corresponding experiments. Products.

http://www.hssdtest.com/

Recommended productsPRODUCTS