Company News

Universal testing mechanism construction and working principle

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Test equipment is the basic guarantee for conducting various experimental research, and various experimental equipment has also emerged due to the needs of experimental research. Tensile performance is a very important performance indicator for engineering materials. In order to meet the tensile testing needs of different materials, domestic and foreign manufacturers have produced many types of tensile testing machines. These test mechanisms are basically similar in construction form, they are all designed according to test specifications, and mainly complete tensile tests of standard samples.

However, with the continuous emergence of new materials, or the speciality and complexity of engineering applications, some non-standard samples usually require anchoring or tensile tests. For non-standard tests, existing testing machine equipment often fails to meet the usage requirements. Re-customizing the testing machine equipment for non-standard specimens will incur large costs, so it is necessary to modify the existing equipment and make it meet the test requirements.

Universal testing machineConstruction and working principle.

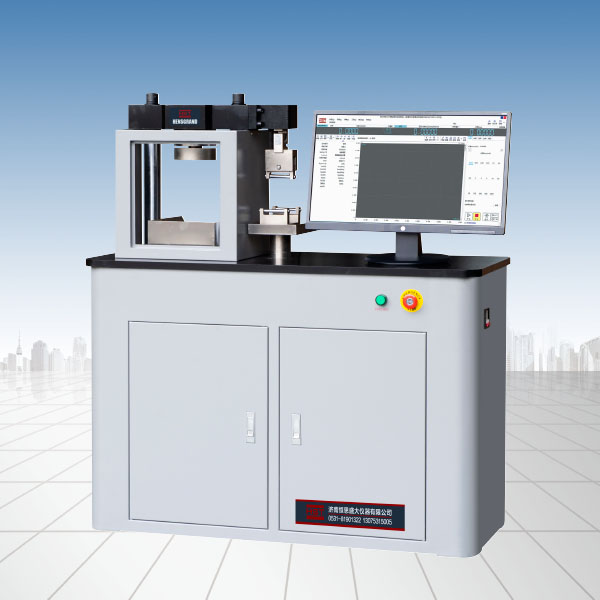

The SHT4605 microcomputer controlled electro-hydraulic servo universal testing machine is mainly composed of a base, 4 columns, 2 screws, upper beams and lower beams. The structure principle is as follows:

(1) The base includes a motor, oil source, and jack, which is the power part of the test machine; (2) The bottom of the 4 columns is fixed to the base table, and the upper beam is fixed to the top of the column through clamps, so that the upper beam and the column form a reaction frame; (3) The 2 screws pass through the base table and are independent of the base table and have no constraints. The screw is driven by a special motor and can rotate simultaneously. While the screw rotates, it can drive the lower beam to move up and down. According to the size of the sample, adjust the lower beam to a suitable position. After the screw stops rotating, the position of the lower beam is fixed; (4) The upper beam and the lower beam are equipped with clamps to support the sample; (5) After the sample is installed, turn on the power supply and oil source, and the jack tops the machine base table, and at the same time drives the 4 columns and the upper beam to move upwards. Because the position of the lower beam is fixed, moving the upper beam upwards will create a tension on the specimen. (6) The stretched space between the upper and lower beams is 710mm.

http://www.hssdtest.com/

Recommended productsPRODUCTS