Company News

Problems and solutions for universal testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Universal testing machineWhen loading, sometimes the load cannot be added or unloaded during loading.

This type of failure occurs frequently and causes many reasons.

①The viscosity of the oil is too low (the oil flows out of the oil return pipe of the oil supply valve when loading). Generally, mineral oil of medium viscosity is used, which does not contain water, acid and other mixtures, does not decompose at room temperature, and does not thicken. If necessary, it can be measured with a viscometer. If the oil is used improperly, it will cause the valve and oil circuit to be blocked and may cause vibration or pipeline leakage. Oil should be used as required in the instructions.

② The oil pressure system has severe oil leakage, and the oil leakage in the oil circuit system generally occurs at the connections of the buffer valve, oil return valve, oil supply valve, oil pump and pipeline. Just tighten the screws after adding pads. If the sealing gasket is broken, it must be removed and replaced with a new one. The gaskets should be made of copper or aluminum alloy.

③The oil collector of the oil pump is not pressed on the pump body. In this way, each load can only reach a certain load, and the load cannot rise any further, and there is no oil flowing out of the oil supply valve return pipe. Exclusion method: Use a wrench to tighten the fixing screws at the rear end of the oil pump. If there is still a problem, remove the oil collector and add a gasket between the oil collector and the pump body.

④ The matching gap between the working piston and the oil cylinder is too large, and the gap is too oil spilled, which can be seen from the oil spill and other outlets. The method is to thicken the viscosity of the oil. If the problem cannot be solved, after precise measurement, you should go to the manufacturer to replace the piston and oil cylinder.

⑤The piston and piston sleeve in the oil supply valve are damaged or the spring becomes soft. In this way, the load that can be achieved by each load remains basically unchanged, and the oil supply valve is noisy. When the load cannot rise, the oil output of the oil supply valve returns the oil pipe is large. The piston and piston sleeve should be removed and ground. If the damage is serious, the spring should be replaced.

⑥The gap between the damping needle and the damping hole of the oil supply valve is too small. Main manifestations: Each load can only reach a certain load. When the load cannot rise again, the oil output of the oil return pipe of the oil supply valve is large. Exclusion method: Take out the damping needle and file part of it with a file along the axial direction of the damping needle.

⑦ The belt that drives the oil pump is loose and slipping. After loading to a certain load, the oil supply valve return pipe does not flow out, and the oil pump does not work sound.

Exclusion method: Loosen the motor fixing screws, adjust the position, tighten the belt, and then tighten the motor fixing screws. If the belt is too deformed, a new belt must be replaced.

http://www.hssdtest.com/

- Previous article:Changes in the new standards of universal testing machines

- Next article:Troubleshooting of universal testing machine

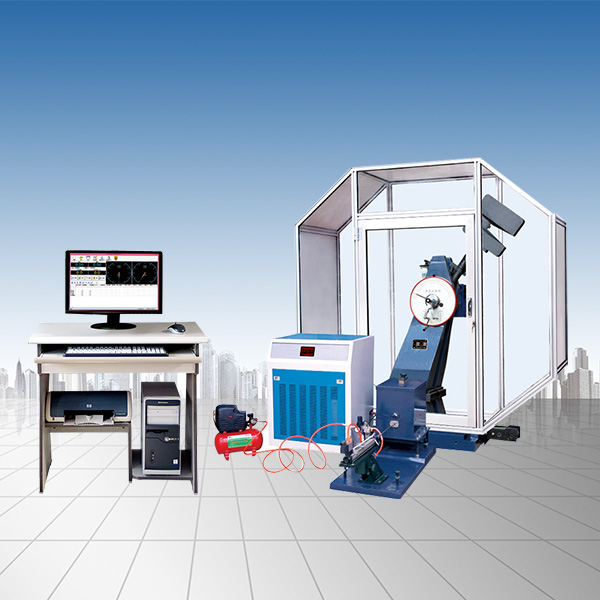

Recommended productsPRODUCTS