Company News

Hydraulic universal testing machine to detect 35CrMo steel

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

35CrMo steel has good comprehensive mechanical properties and is a kind of alloy structural steel commonly used in industrial production, especially in the automotive industry. Because there will be different degrees of torsional prestrained overload during processing and use, such as the moment of starting and shutting down by car transmission shafts, engine crankshafts, etc., these components often cause torsional prestrained overloads, and these overloads will definitely have a certain impact on the conventional mechanical properties and fatigue properties of the material. At present, there are not many research reports on the detection of the mechanical properties of 35CrMo steel after pretorsion and pretension strengthening of hydraulic universal testing machines, especially the high-period and low-period fatigue properties after torsion prestraining.

This chapterHydraulic universal testing machineThe 35CrMo steel was tested as the research object, starting from the perspective of tensile and fatigue properties, and the mechanical properties and high and low cycle fatigue properties of the materials after torsional prestrain were studied. To this end, this paper specially designed samples for both tensile and torsion, fatigue and torsion. Through different angles and different strains of pre-tension, the hydraulic universal test machine systematically studied the mechanical properties of 35CrMo steel after pre-tension and pre-torsion strengthening and fatigue properties of low and high cycles under torsion pre-strain. The hydraulic universal test machine after torsion pre-strain was focused on analyzing the tensile properties, fatigue limits, S-N curves, cyclic hardening and softening characteristics, hysteresis loops, plastic strain energy and cyclic elastic modulus changes. The fractures of high and low cycle fatigue tests were analyzed, and the following main conclusions were obtained:

(1) The hydraulic universal testing machine detects that the 35CrMo steel specimens have no obvious yield platform in tensile and torsional tests; torsional prestrain can improve the yield strength and tensile strength of the hydraulic universal testing machine when tensile detection of the 35CrMo steel specimens, and reduces the tensile strain hardening index and strength coefficient of the specimens; pretension strengthening can improve the shear yield strength of the hydraulic universal testing machine when the 35CrMo steel specimens is twisted, but it has little impact on the shear strength limit on the limit of the shear strength;

(2) The hydraulic universal testing machine detects the high-period fatigue limits of 35CrMo steel at pre-torsion 0, 3π/4 and 7π/4 by lifting method is 321.6MPa, 308.12MPa, and 294.90MPa, respectively; under the same cyclic stress amplitude, the fatigue life of the pre-torsion angle specimen is significantly lower than that of the pre-torsion angle specimen without pre-torsion angle specimen, and the larger the pre-torsion angle, the lower the corresponding fatigue life.

(3) When pre-torsion 0, π/4, 3π/4, 5π/4, hydraulic universal testing machine detects that the low-cycle fatigue test pieces of 35CrMo steel all show cyclic softening phenomenon, and the cycle softening law and attenuation degree are basically the same; after pre-torsion strengthening, the test piece has process hardening, and the width between the unloading curves in the stress and strain hysteresis loop decreases with the increase of the pre-torsion angle, that is, the range of plastic strain in the fatigue cycle decreases; the cyclic elastic modulus of the test piece gradually decreases with the increase of the number of fatigue cycles, and with the increase of the pre-torsion angle, the attenuation trend of the cyclic elastic modulus of the fatigue test piece slows down, and the reduction amplitude also decreases; and the plastic strain energy increases with the increase of the number of fatigue cycles, and with the increase of the pre-torsion angle, the amplitude of the decrease of the plastic strain energy increases.

(4) The hydraulic universal testing machine detects that the high-circumference and low-circumference fatigue cracks of 35CrMo steel both originate on the surface of the specimen, and the cross-section of the crack source area is bright and flat, and a large number of secondary cracks are generated in the crack expansion area; the fatigue step height of the pre-torsion specimen is higher than that of the fatigue step height without the pre-torsion specimen, and increases with the increase of the pre-torsion angle; the instantaneous breaking area of the high and low-circumference fatigue fracture has obvious tough morphology and secondary cracks and cracking phenomena.http://www.hssdtest.com/

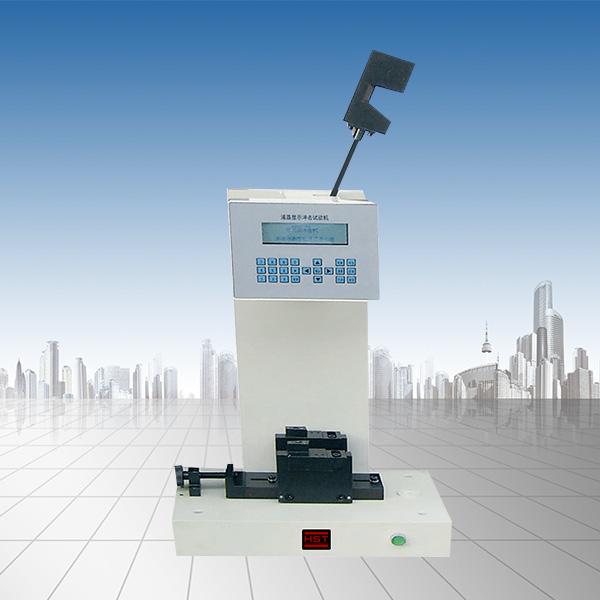

Recommended productsPRODUCTS