Company News

Analysis of the reasons for excessive maximum range error in verification of universal testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Force measurement is widely used in all sectors of the national economy. With the development of science and technology and the need for standardized production, the application of force measurement instruments is becoming more and more widely, and the social ownership is increasing. Metal or non-metallic materials, cement and wood, etc. that are widely used in the construction engineering and machinery manufacturing industries, are determined by enterprises themselves in order to ensure the mechanical properties of the materials. In order to make full use of the properties of materials, theoretical calculations are the basis of design, and the purpose of more economical and product safety has been achieved through force measurement and measurement. Our metrology and verification personnel use various means and methods to provide and ensure the accuracy of the test instruments.

1. Problem raised

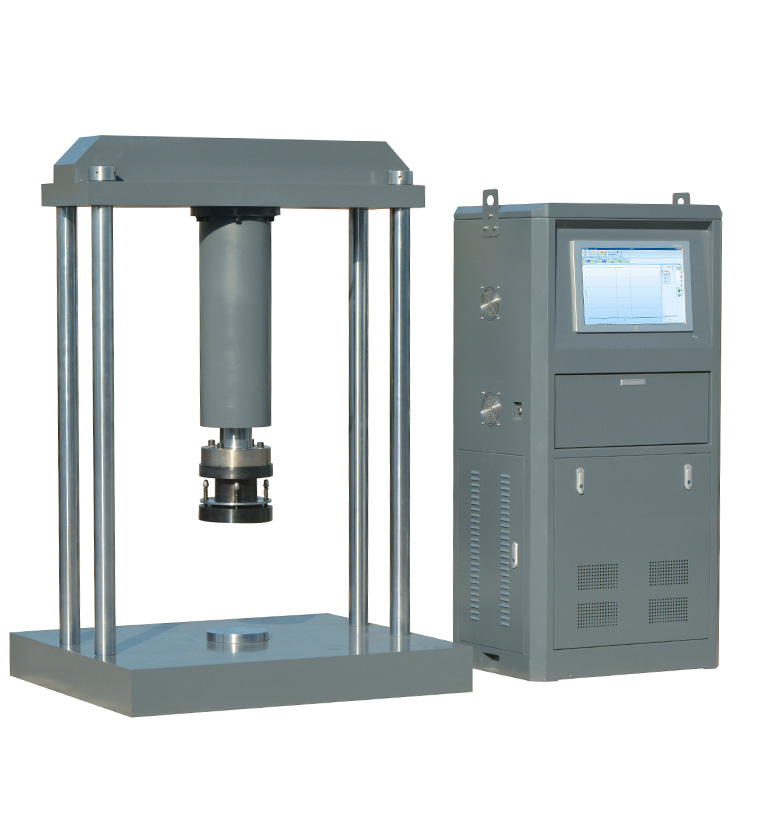

We've been in a few yearsUniversal testing machineIn the verification practice, it was found that some hydraulic universal testing machines, especially those with a long service life and a high frequency of use, were found during verification and testing that the instrument is within the specified error range within a relatively small range that is often used, and often exceeds the specified error range when approaching the measurement range.

The inspection regulations of the material testing machine stipulate that on the basis of qualified appearance and safety performance, a standard force measuring instrument is placed on the workbench of the universal testing machine, and the pointer zero point and balance weight of the universal testing machine are adjusted. After meeting the requirements, pre-pressing it to the corresponding dial test force of the machine three times. Then, three sets of test force values were measured continuously, and the display error and display repeatability error of the universal test machine were calculated. However, the set of test force values collected in actual work sometimes exceed the allowable error range of the universal testing machine of this level, especially the display value deviation of each dial range point.

Below are the measured data of the two machines we measured when we checked the above-mentioned universal testing machine.

2. Cause analysis and conclusion

After we discovered the above problems during the verification process of multiple universal testing machines, we passed the verification after multiple tests at the measuring range point, and the error dropped to the allowable value range. The verification passed, avoiding unnecessary repairs or downgrading and use until scrapped. The reason for the above problems is that I think there are two aspects: First, the experimenter with many years of operating experience can replace the test force with a larger level dial or larger level test instrument in advance before approaching the point of the test force, so the measuring piston and the force measuring piston always fail to reach the range point during work. Over time, the loss of the side wall of the piston side wall is small. Compared with the commonly used range section, the friction force increases, causing the measured force value of the range point to be low; second, the side wall part of the piston is not often used is prone to deposit dirt, and the deposit dirt in the inverted hanging groove connected to the force measuring piston also increases the friction force, causing the measured force value of the range point to be low. After the cause of the problem is found, during the verification, we recommend that the experimenter regularly test the instrument's range, resulting in uniform wear of the relative moving pairs, so that the technical state is often within the allowable error range.

To sum up, during the instrument verification process, the measurement and verification personnel must not only grasp the technical connotation of the verification procedures, but also fully consider various factors affecting the test data from reality to solve problems, grasp the technical quality, and avoid unnecessary premature scrapping of the instrument, shorten the service life and cause economic losses. http://www.hssdtest.com/

Recommended productsPRODUCTS