Company News

Error analysis generated during verification of electronic universal testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1. Errors caused by the detection environment

Electronic universal testing machineThe site, temperature, humidity and vibration of the verification are objective reasons for the error in the detection data during the measurement verification. For example, an electronic pressure testing machine, due to changes in natural weather in spring, summer, autumn and winter, is the mechanical connectors of the pressure testing machine, sensors and standard devices, which will cause slight deviations in the metrological verification data. This slight error should be grasped in the long-term inspection practice, constantly explored and corrected scientifically to ensure the authenticity and reliability of the metrological verification data.

2. Error caused by standard force measuring instruments

At present, most electronic universal testing machines use standard dynamometers (mainly composed of sensors and displays). The quantization errors unique to these standard dynamometers are the direct cause of metrological errors. Although the standard dynamometer used for quantity transmission is performed periodically and laboratory comparison according to national regulations, since the standard dynamometer is dynamic in long-term calibration, it will naturally cause wear and fatigue during the moving and use process, which will cause certain errors during the calibration process. Therefore, standard dynamometers should strengthen supervision and control, strengthen the maintenance of universal material testing machines, confirm and conduct regular and irregular periodic verification after each handling, and conduct repetitive and stability tests in accordance with the 1033 metrological standard assessment specifications every year to ensure the accuracy and reliability of the metrological verification data.

3. Error caused by verification method

Currently, the cited procedures for verification of electronic universal testing machines are:

JJG139-1999 "Tenering Pressure and Universal Material Testing Machine" verification regulations, JJG475-2008 "Electronic Universal Testing Machine" verification regulations, JJG474-2008 "Wood Universal Material Testing Machine" verification regulations, JJG157-2008 "Non-metal tensile pressure and Universal Material Testing Machine" verification regulations.

In the above procedures, there are two methods for calculating the display error and the display repeatability:

4. Errors caused by operation of measurement and verification personnel

In the measurement and verification work, each verification personnel has different professional levels. Due to their different technical level and fineness, even if the same measurement and verification procedure is used for verification of the same electronic universal material testing machine, there will be slight errors. Furthermore, the speed control and reading methods of each inspector operating the oil inlet valve during calibration are different. Some inspectors can operate the oil inlet valve to the display device to clearly identify it according to the last number, and some people can read data synchronized with the standard force measuring instrument. Some checkers can control the oil inlet speed very well, while some people move very hard, and the oil inlet is moving forward and backward. The existence of friction force of the oil tank will inevitably affect the calibration results.

5. Full preheating and prepressing of standard force measuring instruments and electronic pressure testing machines

At present, the inspector's workload is heavy, and the preheating and pre-pressure before the inspection is not done well. A large part of the standard dynamometer and electronic universal testing machine are composed of electronic components, which fully preheat the electronic components. The preheating time is the key to ensuring the stability of the display value of the standard dynamometer and electronic universal testing machine. Pre-pressing can eliminate friction from mechanical parts. It is not too much to pre-press three times before verification in the regulations.

6. Errors caused by incorrect installation of the test machine

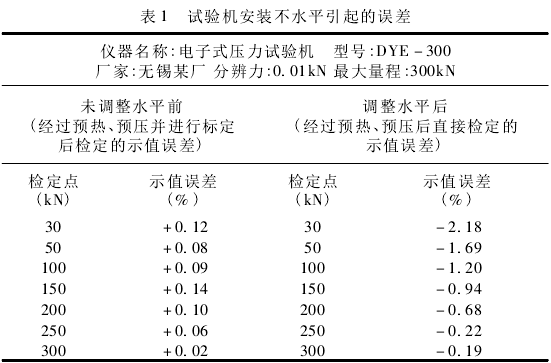

If the test machine is not installed horizontally, it will increase the friction between the moving parts, affecting the vertical installation, thereby causing errors in the verification data. Here, Jinan Hengsi Shanda Instruments quotes a set of data from daily calibration work (as shown in Table 1) to illustrate.

From Table 1, it can be seen that the data verification after calibration before the level is adjusted is qualified, but the verification data will exceed the limit once the level is adjusted. Therefore, during verification, especially when the pressure tester is first checked, it is necessary to check whether the press is installed at the same level.

7. The upper and lower pressure plates and spherical surfaces have not been cleaned or grinded

At present, the workbench (upper or lower workbench) of the pressure tester has a ball head, which is intended to eliminate lateral forces. It is ensured that the force applied by the pressure test machine is consistent with the force exposed by the object being tested. However, due to the unsatisfactory bridging between the ball head and the mount, things are contrary to their expectations, resulting in the force generated by the pressure test machine not acting perpendicularly on the test block being tested, and an error risk is introduced. For example: We checked an electronic pressure test machine for Changting beam field of China Railway 22nd Bureau Group Co., Ltd. The calibration results are accurate within the specified accuracy level. However, unexpectedly, the difference between the results of the C55 concrete test blocks in the same group by the electronic pressure test machine and the actual results is about 150kN, which is far beyond the 7% error between laboratories. After disassembly analysis, it was found that the screw connecting the ball head of the pressure plate on the test machine was severely deformed and inclined, and the ball head became a single-sided force. It can be seen from this that it is necessary to clean and grind the upper and lower pressure plates and spherical surfaces before conducting pressure test and verification.

8. Error caused by resolution of the pressure tester under test

Since the resolution of the pressure test machines being inspected is different, some are 0.1kN, some are 0.01 kN, and some are 0.001 kN, the error caused by the different number of bits can be read by the verification personnel when reading the test machine.

http://www.hssdtest.com/

Recommended productsPRODUCTS