Company News

What points do you need to check when repairing a universal test machine?

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1.Universal testing machineMeasurement accuracy during maintenance. Accuracy issues, including force measurement accuracy, speed accuracy, deformation accuracy, and displacement accuracy. These accuracy values can reach plus or minus 0.5. But for ordinary manufacturers, achieving 1% accuracy is enough. In addition, the force resolution can almost reach tens of thousands of parts of the tension machine maintenance

2. Test speed during maintenance of universal testing machine. Some of the market equipment are 10~500mm/min, and some are 0.001~500mm/min. The former generally uses ordinary speed control systems, which are low in cost and rough affects accuracy; the latter uses servo systems, which are expensive and have high accuracy. For flexible packaging companies, if you choose a servo system, the speed control range of 1~500mm/min is enough, which does not affect the accuracy, and the price is within a reasonable range.

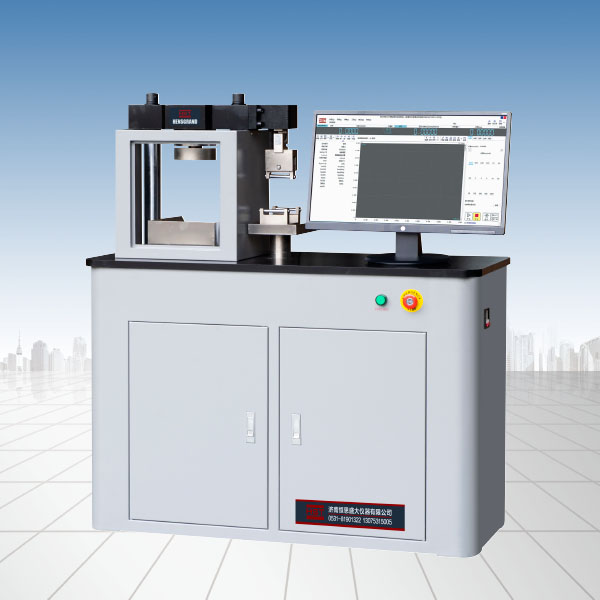

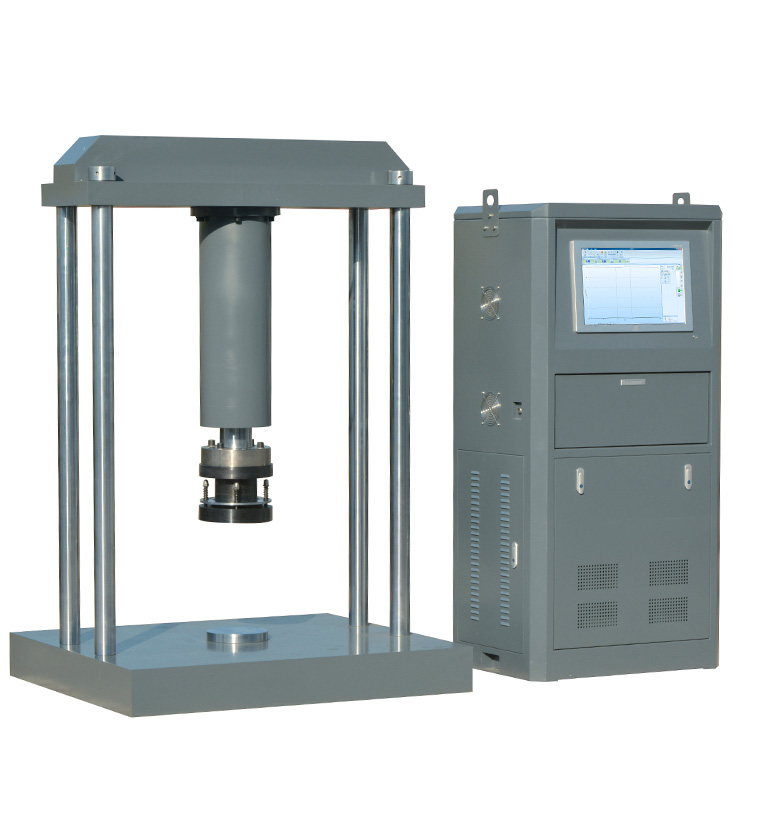

High temperature universal material testing machine

3. The main mechanical configurations of universal testing machine maintenance products: transmission, with lead screw transmission and rack transmission. The former is expensive, used for high precision and high test repeatability; the latter is cheap, used for low precision and low test repeatability. The lead screw and metal material testing machine have a decisive effect on the measurement of tensile accuracy. Generally, there are ball screws, trapezoidal screws, and general screws. Among them, the accuracy of the ball screw, but its performance can only be achieved by operating the computer servo system, and the whole set is also relatively expensive. The accuracy required for flexible packaging can be achieved by using general lead screws and trapezoidal lead screws, that is, 0.5-1% accuracy. Drive, with geared and chain drive, the former is expensive for high precision; the latter is cheap for low precision. The main cost of sensors lies in their lifespan. Optoelectronics is the most advanced technology, which is generally available for more than 100,000 times. Imported and some domestic joint venture manufacturers can achieve better technology.

4. When repairing the universal testing machine, it is possible to perform experimental projects. Flexible packaging requires that one tension machine is used for multiple purposes, that is, on the basis of equipped with different fixtures, tensile, compression, bending, tearing, shear, 180-degree peeling, and 90-degree peeling tests can be performed. In addition to the above items, some tensile machines on the market can also test the friction coefficient because of their high sensor accuracy (some reach one in 250,000).http://www.hssdtest.com/

Recommended productsPRODUCTS