Company News

Adjustment method of universal testing machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The "universal" test machine uses it to perform tensile, bending, compression and shear tests to perform performance evaluation, application development research and quality control of materials. Developed electronics improves the performance of these devices, making them easier to operate and less expensive.

Universal testing machineThrough adjustments at different speed levels, the splines of plastic material are stretched, bent, compressed or pulled, which is a common equipment in plastic mixing laboratories. During the preparation of compound mixing, UTM testing materials can be used to determine whether the material is suitable for certain specific processing applications or terminal applications. UTM can also be used for product quality control to ensure consistency between batches of product quality.

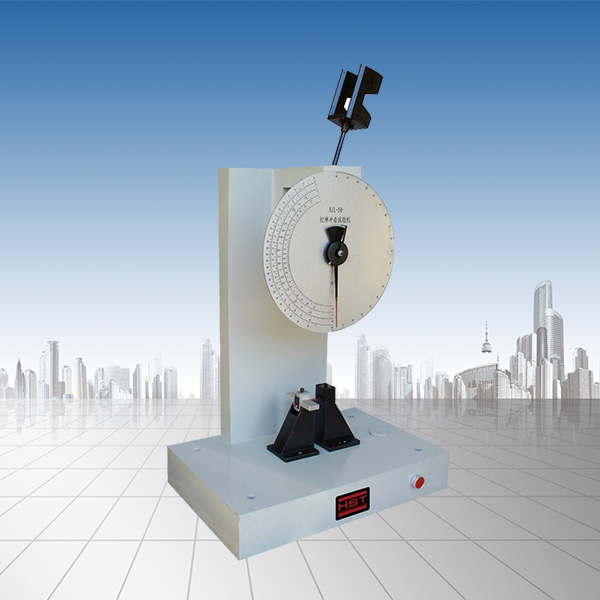

The UTM test machine includes one or more vertically loaded columns, a fixed horizontal base is installed on the columns, and a movable horizontal cross head (cross beam) on the top. In today's UTM testing machines, ball screws are usually on the columns to fix the movable cross head. The size of the UTM is characterized by a frame bearing level and a dynamometer measuring load/tension force. The dynamometer is attached to a movable cross head driven by an electric motor or hydraulic device. The series of dynamometers with fixtures measure the magnitude of force, and the results can be displayed through a digital display or PC. Many UTMs have interchangeable dynamometers and therefore can match the different materials tested. Static tests are carried out using standard electronic universal testing machines, and the usual loading speed range is 0.001~20 in./min (1in.=2.54cm). Dynamic or cyclic tests such as crack growth and fatigue tests are usually performed using a hydraulic servo system UTM test machine, which is longer and has a lower load.

Currently, common items tested with universal testing machines are tensile strength and tensile modulus, bending strength and modulus. When performing tensile tests according to ASTM D 638 and ISO 527, there are clamps on both ends of the spline. One clamp is stationary and the other is fixed on the cross head, moving away from the fixed clamp, pulling the spline until the spline breaks, and the cross head will automatically stop when it breaks. During bending test (ASTM D790, D6272 and ISO178), the spline is placed on the two supporters of the test machine fixed machine tool. In this test, the direction of the crosshead movement is opposite to the direction of movement in the tensile test, pushing towards a center without support instead of traction until the spline bends or even breaks. Because most thermoplastic materials do not break during this test, it is impossible to calculate the fracture bending strength. Therefore, the standard test method requires the calculation of bending stress when the strain is 5%.

The capacity of commonly used electronic UTM testing machines is 100~135,000 lb. The larger the size, the higher the cost. Generally speaking, vertical devices are smaller and easier to operate, and can also make difficult samples such as films as heavier injection molded parts by the gravity of the sample itself. The single column UTM test machine has a lower force range and a lower price, and its structural capacity is generally 1000 lb. The structural capacity of the gate-type UTM test machine can reach 1000~135,000 lb. The dynamometer is also classified based on a certain force value suitable for the structure of the UTM test machine and the sample. For example, a 100 lb dynamometer is installed in a 1000 lb mold frame and can provide a 100 lb test load. The capacity of the dynamometer should not exceed the sample's predicted fracture load, otherwise it will affect the accuracy of the test results.

Unlike the electronic UTM test machine used for static testing, the hydraulic servo UTM test machine can undergo dynamic testing and fatigue testing. This requires repeated stress application to be performed for a load-release cycle. For example, fatigue crack growth tests, users expect to know how many cycles the material to be tested will break. The stress required for dynamic testing of universal testing machines is smaller than that required for static testing of electronic universal testing machines. The frame capacity of the hydraulic servo system test machine ranges from 100 lb to several tons, and the price is usually 2 to 3 times that of the electronic mechanical test machine. It is basically used for fatigue testing of metal materials, but it is also becoming more and more widely used in automotive plastics, aerospace plastics, biomedical plastics, and plastics for electronic components, because structural components with good fatigue resistance are needed in these fields.

- Previous article:Application scope of tension machine

- Next article:Determinants of performance and accuracy of tensile tester

Recommended productsPRODUCTS