Company News

New developments in sensor data

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

With the widespread use of sensors, IT managers from major manufacturers and companies are exploring ways to integrate sensor information into the entire IT network. The goal? It is to not only use sensors to track, count and monitor things, but also combine sensor data with other business indicators for analysis to identify the long-term development trends of things and gain a deeper understanding of them.

Previously, most sensors were fixed inside the machine, using private communication protocols to send information to a closed system. However, in the past five years, new technologies have spawned a new generation of sensors - mobile, networkable sensors, making sensors more widely used.

Workshop administrators in companies may pay more attention to automatically controlling sensor information, device administrators may pay more attention to monitoring sensor information, while sales administrators may pay more attention to supply chain sensor information. The problem naturally arises, why not integrate these sensor information into a centralized control network and manifest it in the same business environment?

The answer is, because at least for now, it's too complicated to do so. For such a fusion, there are dual barriers to technology and culture.

First, there are a lot of protocols in the sensor industry. In the manufacturing field alone, there are 250 different private protocols. Even wireless sensor networks using IP protocols often have to use different non-standard versions because the sensors have different low power levels and processing capabilities.

Cisco and sensor network manufacturer Arch Rock jointly formed an IETF working group to develop wireless sensor network standards based on IP routing technology, but this process can take years. More importantly, in most enterprises, there is a cultural difference between the workshop administrator or supply chain administrator who controls the sensor network and the CIO who runs the enterprise IT.

Under special pressure, some companies have begun to investigate the possibility of integration. The following are two typical cases, both of which are forced by rising costs and lack of energy supply, and represent two different convergence methods, but the long-term goals of these projects are consistent: fusing sensor data into the business management process to improve efficiency and reduce costs.

Operators and equipment personnel are concerned about warnings and alarm information issued by the sensor network in order to respond in a timely manner and deal with it quickly. Common problems such as refrigeration failures.

The company's IT department is more concerned with how to use standard methods to analyze and process information. Cultural differences are the challenge of integration.

- Previous article:New textile standards are issued

- Next article:Testing of packaging materials

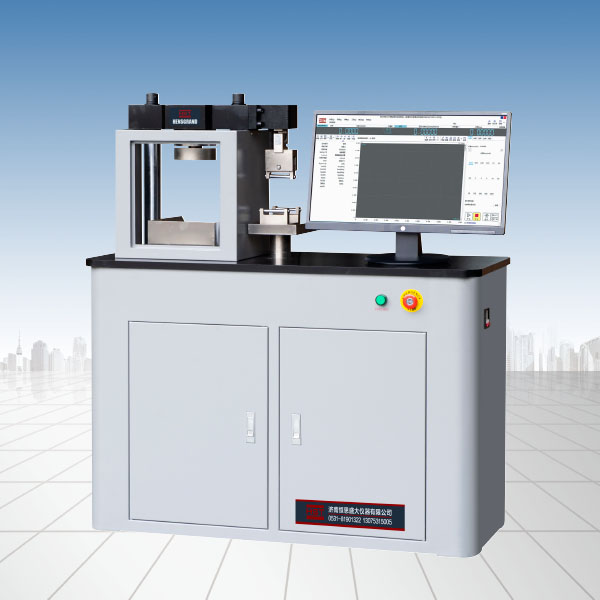

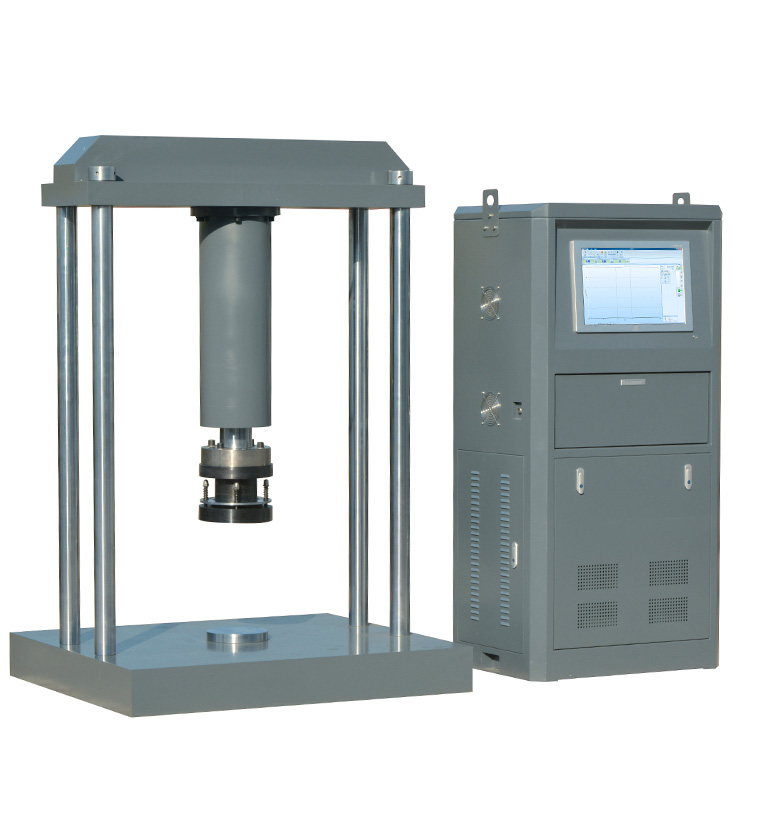

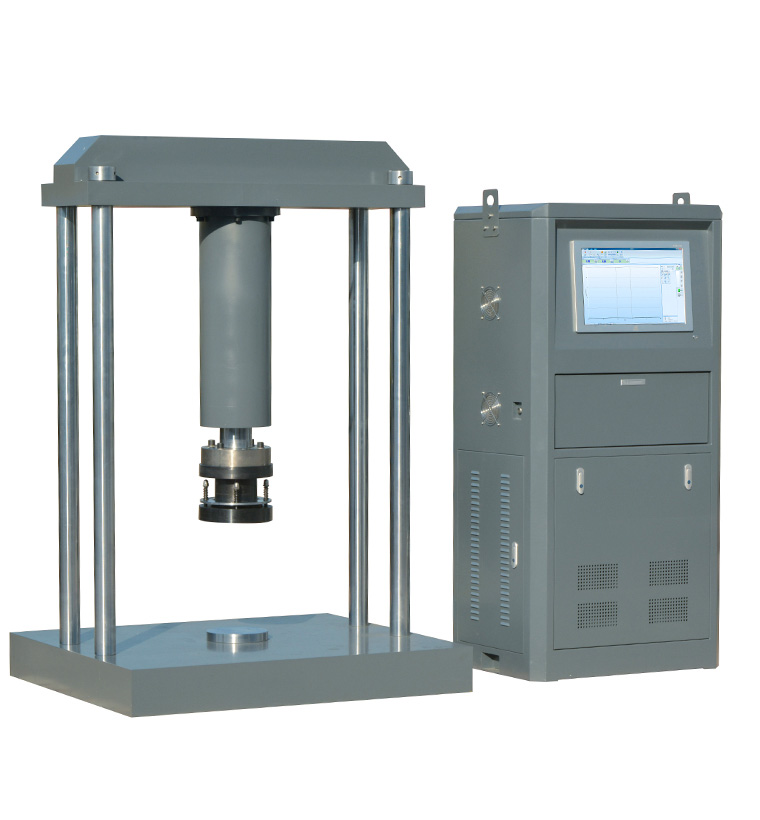

Recommended productsPRODUCTS