WAL microcomputer controlled horizontal tensile tester

WAL microcomputer controlled horizontal tensile tester

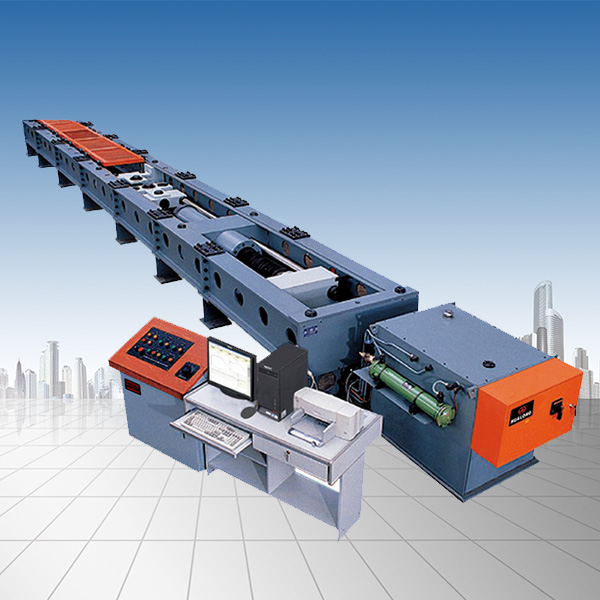

As shown in the figure, the product is produced by Jinan Hengsi Shanda Instrument Co., Ltd.WAL microcomputer controlHorizontal tensile testing machine, the following are the detailed information of the WAL microcomputer-controlled horizontal tensile test machine we introduced to you.

1. Purpose and characteristics

The WAL microcomputer-controlled horizontal tensile tester meets the tensile test of long samples and full-size samples. This product is mainly used for tensile performance tests of various metal components, steel cables, chains, anchor chains, hoisting belts, cables, separation discs, etc.

The WAL microcomputer-controlled horizontal tensile test machine adopts the steel plate welded frame structure, the sectional moving beam adjusts the test space, the single-outlet double-acting piston cylinder applies the test force, and the servo control test process, the load sensor measures the force, and the microcomputer displays the test force and the test curve.

2. Main technical parameters

name | WAL microcomputer controlled horizontal tensile tester |

model | WAL-600, 1000, 2000, 3000 |

Testing force (kN) | 600, 1000, 2000, 3000 |

Test force measurement range | 4%~100%FS |

Test force measurement accuracy | ±1% |

Displacement display error | ±1% |

Stress control speed | 1-45Mpa/s |

Constant stress control accuracy | ±1% |

Tensile distance (excluding piston stroke) | 0--10000mm, can be made according to the user's request. |

Cylinder stroke | 500mm (can be made according to user requirements) |

Sample clamping method | Standard is a pin, and hydraulic clamping can also be used as required. |

Test machine effective space | The width is 750mm, and can be made according to the user's request. |

Control test method | Automatic servo control of microcomputer, or manual valve control |

Trend space adjustment method and interval | Hand-push or electric adjustment; adjustment spacing is 500mm; |

Fixing method of moving beams | Manual latch fixation or hydraulic automatic latch fixation |

Computer configuration | Lenovo brand computer |

Printer configuration | HP A4 format color inkjet printer |

Software Configuration | 1 set of test software under the Chinese and English WINDOWSXP platform |

Power supply voltage | The conventional voltage is 220V/380V, and can also be configured according to the standard voltage of the country where the use is used. |

3. Product functions

(1) Control unit: The control system is a computer software and hardware technology, combined with semiconductor technology, which is reliable, advanced, easy to operate and flexible in measuring force, displacement, deformation and speed control.

(2) Microcomputer system: Lenovo brand microcomputer is used as the host to complete the functions of setting the whole machine test, data acquisition, computing processing, displaying the printing test results, etc.; it is equipped with the KQL-PowerTest2001 Chinese and English version intelligent testing software package for the test machine, which can measure and judge various performance parameters of various material tests based on national standards, international standards or standards provided by users, and calculate and process the data; then output test reports and test curves in various required formats.

(3) Safety protection: The WAL microcomputer-controlled horizontal tensile tester equipment is equipped with mechanical limit protection, automatic overload shutdown protection, automatic overcurrent and leakage power outage protection, emergency switch and other protection functions.

(4) Safety protection: A mesh safety protection net is installed in the test area. The protection net can be easily pushed and pulled and opened, which is convenient, safe and reliable.

4. Product Advantages

(1) The WAL microcomputer-controlled horizontal tensile test machine adopts a manual-automatic integrated control operation mode, which can be automatically controlled by the computer or manually operated, greatly improving work efficiency and reducing the labor intensity of the operator;

(2) Use a spoke-type load sensor, with high accuracy and stable performance;

(3) Italian imported oil pump unit with low noise and stable oil circuit without impact;

(4) Hydraulic seal adopts a double seal structure to effectively prevent oil leakage and oil leakage;

(5) The force-pressure cross beam connected to the piston head is equipped with a moving car, reducing various mechanical frictions.

Note: The above parameters are for reference only. Please focus on the real equipment in detail!

Recommended informationNEWS

- [2025-07-11]What are the calibration methods for electronic tensile testing machines?

- [2025-06-11]How to maintain and maintain the test machine

- [2025-06-11]Faced with a fiercely competitive market, what should China's lock industry make adjustments?

- [2025-05-20]Gate terminal tensile testing machine

- [2025-05-20]How to install and operate the tensile tester

- [2025-04-09]A list of test standards for rubber and its products

- [2025-04-09]Explanation of 9 test items of wire tension testing machine

- [2025-03-25]Common obstacles and methods for e-tension testing machines

- [2025-03-25]What should be paid attention to when operating and testing the impact test machine?

- [2025-03-20]Find different plastic test

- [2025-03-20]Characteristics and types of electro-hydraulic servo systems

- [2025-03-14]Process Standards of Tensile Testing Machine

- [2025-03-14]Test machine repair, test machine failure

- [2023-11-28]Hengsi Electronic Universal Testing Machine Hydraulic Universal Testing Machine Loading and Delivering

- [2023-11-27]Functions of electronic universal testing machine

- [2023-11-14]Breaking tension of wire rope

- [2023-11-03]Preparation of tensile test specimens of glass fiber woven fabric

- [2023-10-16]Wire and cable tension testing machine