Company News

15 Factors Influencing Mechanical Tensile Test

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1 The accuracy and bias of tensile experimental strength and ductility measurement depends on whether the specified experimental methods can be strictly adhered to and is affected by equipment and data elements, sample preparation and experiments, and measurement errors.

2 The consensus on the re-test of the same data depends on the averageness of the data, the repetition of the sample preparation, the experimental premise and the determination of tensile experimental parameters.

3 The equipment elements that can affect the consequences of the experiment include: the rigidity of the tensile experimental machine, shock absorption ability, inherent frequency and component of the moving parts; the accuracy of the force pointer and the application of internal forces of the experimental machine; the appropriate acceleration speed, the use of appropriate forces to center the sample, the parallelism of the fixture, the clamping force, the size of the control force, the compatibility and calibration of the extensometer, the loss of heat (through fixture, the extensometer or auxiliary installation), etc.

4 The data elements that can affect the experimental consequences include: representativeness and averageness of the experimental data, sample type, sample preparation (external brightness, dimensional accuracy, transition arc at the end of the gauge distance, taper inside the gauge distance, bending specimens, thread mass, etc.).

5 Some data are very sensitive to the brightness of the specimen (see Note 8). It is necessary to grind to fantasy brightness, or polish to obtain accurate consequences.

6 For forged, rolled, forged or other non-processed surface morphology, the experimental consequences can be affected by appearance characteristics (see Note 14).

7 Samples taken from parts or components, such as epitaxial or risers, may be self-produced casts (eg, ridge-shaped test blocks) that do not have representative parts or components.

8 The size of the sample can affect the experimental consequences. Regarding cylindrical or rectangular specimens, changing the specimen size generally has little impact on yield strength and tensile strength, but if there is a change, it can affect the yield strength, elongation and cross-section shortening. The elongation value measured by the divergent sample is compared with the following formula:

L0/(A0)1 / 2 (X1.1)

Among them:

L0 = original gauge distance of the sample

A0 = original cross-sectional area of the sample

9 Samples with a smaller L0/(A0)1/2 ratio usually result in a larger elongation and cross-sectional shortening, such as the width or thickness of the rectangular tensile sample added, which is the case.

10 Adhere to the fixed small value of L0/(A0)1/2r ratio, but the impact is not great. Since adding the size of the scale sample in Figure 8, it is possible to find that elongation and area shortening are added or reduced, depending on the data and experimental premises.

11 A 1% taper within the gauge distance can cause a decrease in elongation value. A taper of 1% will reduce elongation by 15%.

12 Changes in strain speed can affect yield strength, tensile strength and elongation values, especially information about high sensitivity and rationality in strain speed. The yield strength and tensile strength in the mortal world will be added with the addition of strain speed. Although the impact on tensile strength is not obvious, the elongation value generally decreases with the addition of strain speed.

13 The brittleness data requires careful preparation of samples, high-quality external brightness, large transition arcs at the end of the gauge, and local large-size threads. Deeper dots or scratches are not allowed to be used as gauge marks.

14 Using flattening tube products for experiments can change the characteristics of the data. In the mortal world, the unevenness in the flattened area can affect the experimental consequences.

15 The measurement errors that affect the experimental consequences include: calibration of experimental force, extensometer, micrometer, gauges and other measurement installations, diagrams record installation adjustments and zeroing, etc.

- Previous article:Requirements for fixture materials of tensile testing machines

- Next article:9 precautions for acceptance of test machine

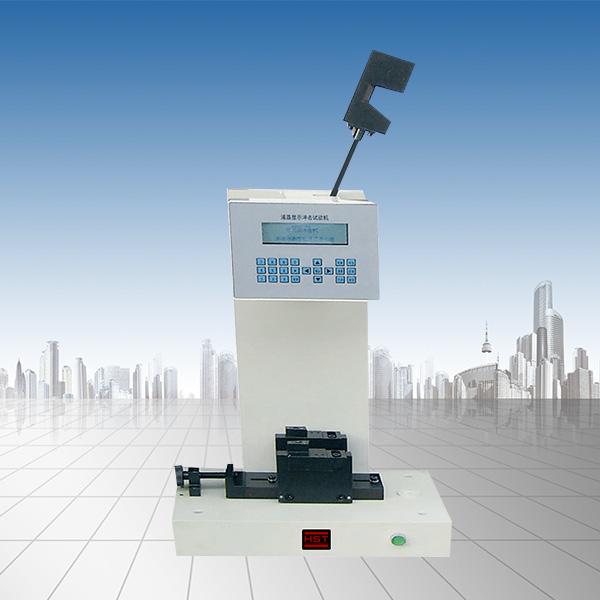

Recommended productsPRODUCTS